| [1] |

YE ZH, WANG L P, GU Y G, et al.. A laser triangulation-based 3d measurement system for inner surface of deep holes[C]. Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, ASME, 2018.

|

| [2] |

丁超, 唐力伟, 曹立军, 等. 深孔内表面结构光图像几何畸变校正[J]. 光学 精密工程,2018,26(10):2555-2564. doi: 10.3788/OPE.20182610.2555DING CH, TANG L W, CAO L J, et al. Geometric distortion correction for structured-light image of deep-hole inner-surface[J]. Optics and Precision Engineering, 2018, 26(10): 2555-2564. (in Chinese) doi: 10.3788/OPE.20182610.2555

|

| [3] |

刘玉洁, 朱韶平. 基于全局和局部多特征的图像增强算法[J]. 液晶与显示,2020,35(5):508-512. doi: 10.3788/YJYXS20203505.0508LIU Y J, ZHU SH P. Image enhancement algorithm based on global and local multi features[J]. Chinese Journal of Liquid Crystals and Displays, 2020, 35(5): 508-512. (in Chinese) doi: 10.3788/YJYXS20203505.0508

|

| [4] |

朱烨. 深孔类零件内表面三维综合测量技术的研究[D]. 合肥: 中国科学技术大学, 2018.ZHU Y. Research of 3D measurement technology for inner surface of deep holes[D]. Hefei: University of Science and Technology of China, 2018. (in Chinese).

|

| [5] |

MCGUIGAN M, CHRISTMAS J. Automating RTI: automatic light direction detection and correcting non-uniform lighting for more accurate surface normals[J]. Computer Vision and Image Understanding, 2020, 192: 102880. doi: 10.1016/j.cviu.2019.102880

|

| [6] |

WAKAYAMA T, TAKAHASHI Y, ONO Y, et al. Three-dimensional measurement of an inner surface profile using a supercontinuum beam[J]. Applied Optics, 2018, 57(19): 5371-5379. doi: 10.1364/AO.57.005371

|

| [7] |

YOKOTA M, KOYAMA T, TAKEDA K. Digital holographic inspection system for the inner surface of a straight pipe[J]. Optics and Lasers in Engineering, 2017, 97: 62-70. doi: 10.1016/j.optlaseng.2017.05.012

|

| [8] |

经周, 樊嘉杰, 陈威, 等. 光净化用紫外LED阵列模组的均匀照度优化设计[J]. 金宝搏188软件怎么用

与光电子学进展,2019,56(19):192303.JING ZH, FAN J J, CHEN W, et al. Optimized uniform illumination design of ultraviolet LED array module used in light purification[J]. Laser &Optoelectronics Progress, 2019, 56(19): 192303. (in Chinese)

|

| [9] |

胡莹, 苏宙平, 曹晶辉. 实现白光LED阵列色温分布均匀化技术研究[J]. 液晶与显示,2018,33(4):326-337. doi: 10.3788/YJYXS20183304.0326HU Y, SU ZH P, CAO J H. Design of white LED array for uniform correlated color temperature distribution[J]. Chinese Journal of Liquid Crystals and Displays, 2018, 33(4): 326-337. (in Chinese) doi: 10.3788/YJYXS20183304.0326

|

| [10] |

MA Y P, LUO X B. Small-divergent-angle uniform illumination with enhanced luminance of transmissive phosphor-converted white laser diode by secondary optics design[J]. Optics and Lasers in Engineering, 2019, 122: 14-22. doi: 10.1016/j.optlaseng.2019.05.022

|

| [11] |

付瀚毅, 刘原原. 高均匀性小孔径金宝搏188软件怎么用

照明系统[J]. 液晶与显示,2018,33(7):548-554. doi: 10.3788/YJYXS20183307.0548FU H Y, LIU Y Y. High uniformity laser illumination system with small aperture[J]. Chinese Journal of Liquid Crystals and Displays, 2018, 33(7): 548-554. (in Chinese) doi: 10.3788/YJYXS20183307.0548

|

| [12] |

BABADI S, RAMIREZ-INIGUEZ R, BOUTALEB T, et al. Symmetric and asymmetric freeform lens to produce uniform illumination[J]. Optical Engineering, 2020, 59(1): 015102.

|

| [13] |

周强, 王峥, 李敏. 基于菌群算法的飞机铆钉表面缺陷检测系统光源优化控制[J]. 液晶与显示,2017,32(11):895-904.ZHOU Q, WANG ZH, LI M. Bacterial foraging optimization control of light source for surface defect detection system based on colony algorithm[J]. Chinese Journal of Liquid Crystals and Displays, 2017, 32(11): 895-904. (in Chinese)

|

| [14] |

李炳乾, 罗明浩, 俞理云, 等. COB封装全光谱LED光源及其光电特性[J]. 液晶与显示,2018,33(11):931-935. doi: 10.3788/YJYXS20183311.0931LI B Q, LUO M H, YU L Y, et al. Full spectrum LED light in COB package and its characteristics[J]. Chinese Journal of Liquid Crystals and Displays, 2018, 33(11): 931-935. (in Chinese) doi: 10.3788/YJYXS20183311.0931

|

| [15] |

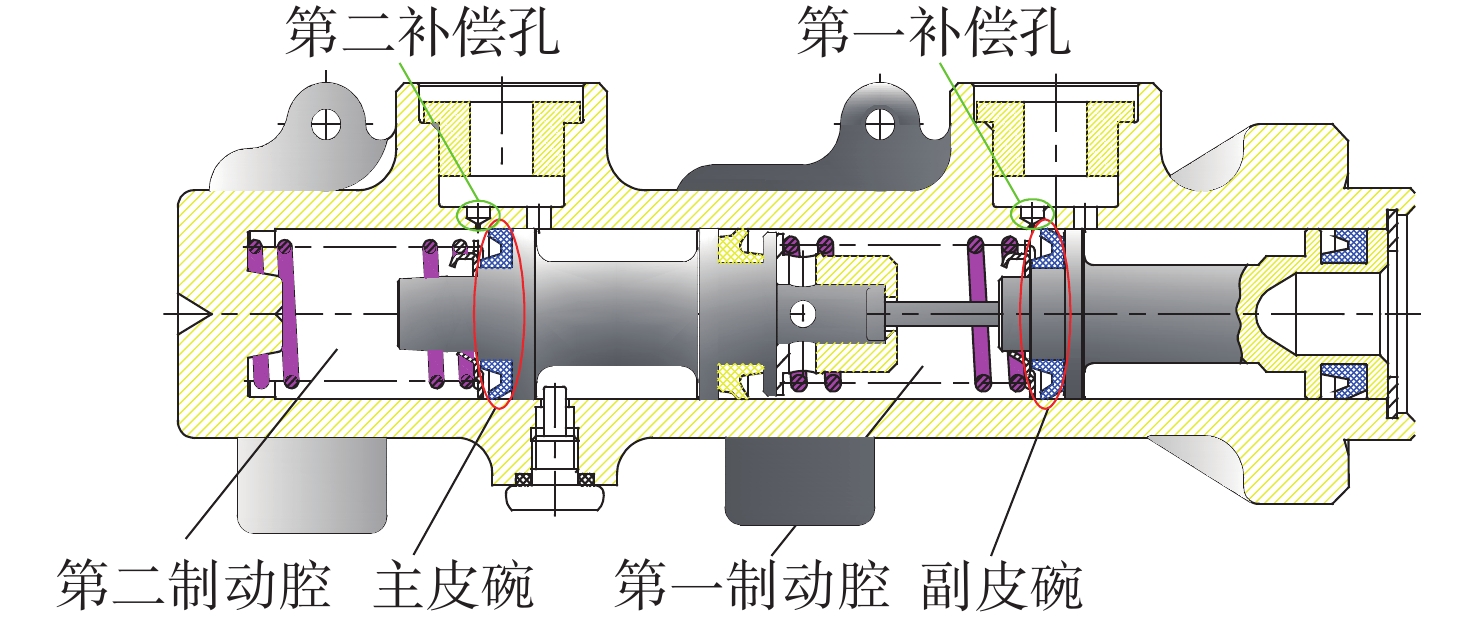

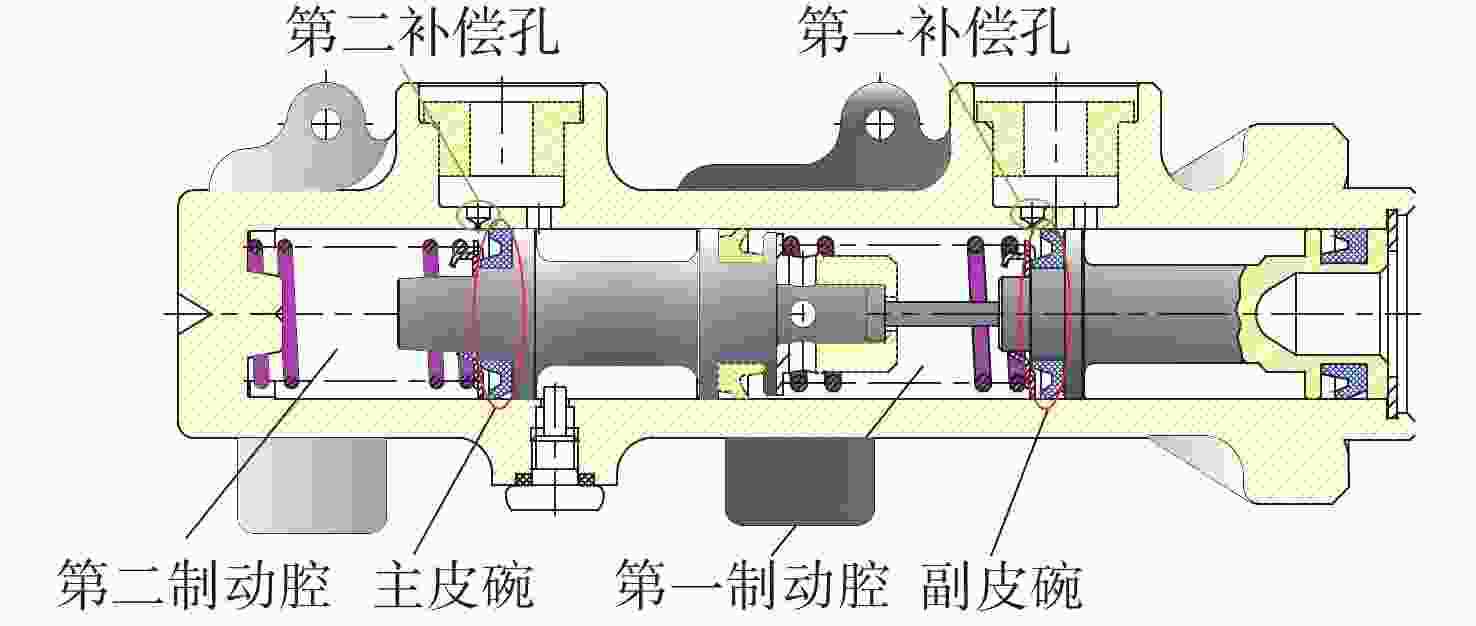

姜涛, 张桂林, 高俊鹏. 制动主缸补偿孔位置检测误差分析与补偿[J]. 光学 精密工程,2020,28(5):1094-1100.JIANG T, ZHANG G L, GAO J P. Error analysis and compensation in position measurement of brake master cylinder compensation hole[J]. Optics and Precision Engineering, 2020, 28(5): 1094-1100. (in Chinese)

|

| [16] |

高俊鹏, 姜涛, 张桂林, 等. 汽车制动主缸补偿孔形位尺寸检测双远心光学系统研究[J]. 计量学报,2017,38(3):262-266.GAO J P, JIANG T, ZHANG G L. Research on double telecentric optical system for the form and position detection of automobile brake cylinder compensation hole[J]. Acta Metrologica Sinica, 2017, 38(3): 262-266. (in Chinese)

|

| [17] |

袁银麟, 郑小兵, 吴浩宇, 等. 大口径积分球参考光源的均匀性研究[J]. 光子学报,2015,44(4):0422003. doi: 10.3788/gzxb20154404.0422003YUAN Y L, ZHENG X B, WU H Y, et al. Uniformity research of integrating spheres reference light source with large exit aperture[J]. Acta Photonica Sinica, 2015, 44(4): 0422003. (in Chinese) doi: 10.3788/gzxb20154404.0422003

|

下载:

下载: