Light modulation performance control of the coating on the repaired damage sites in fused silica surface

-

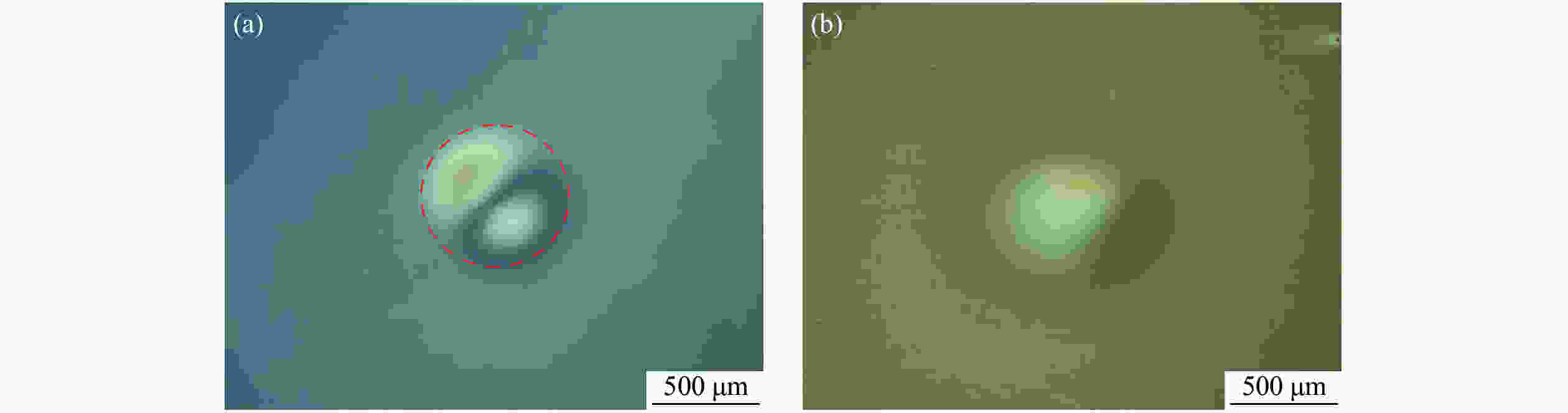

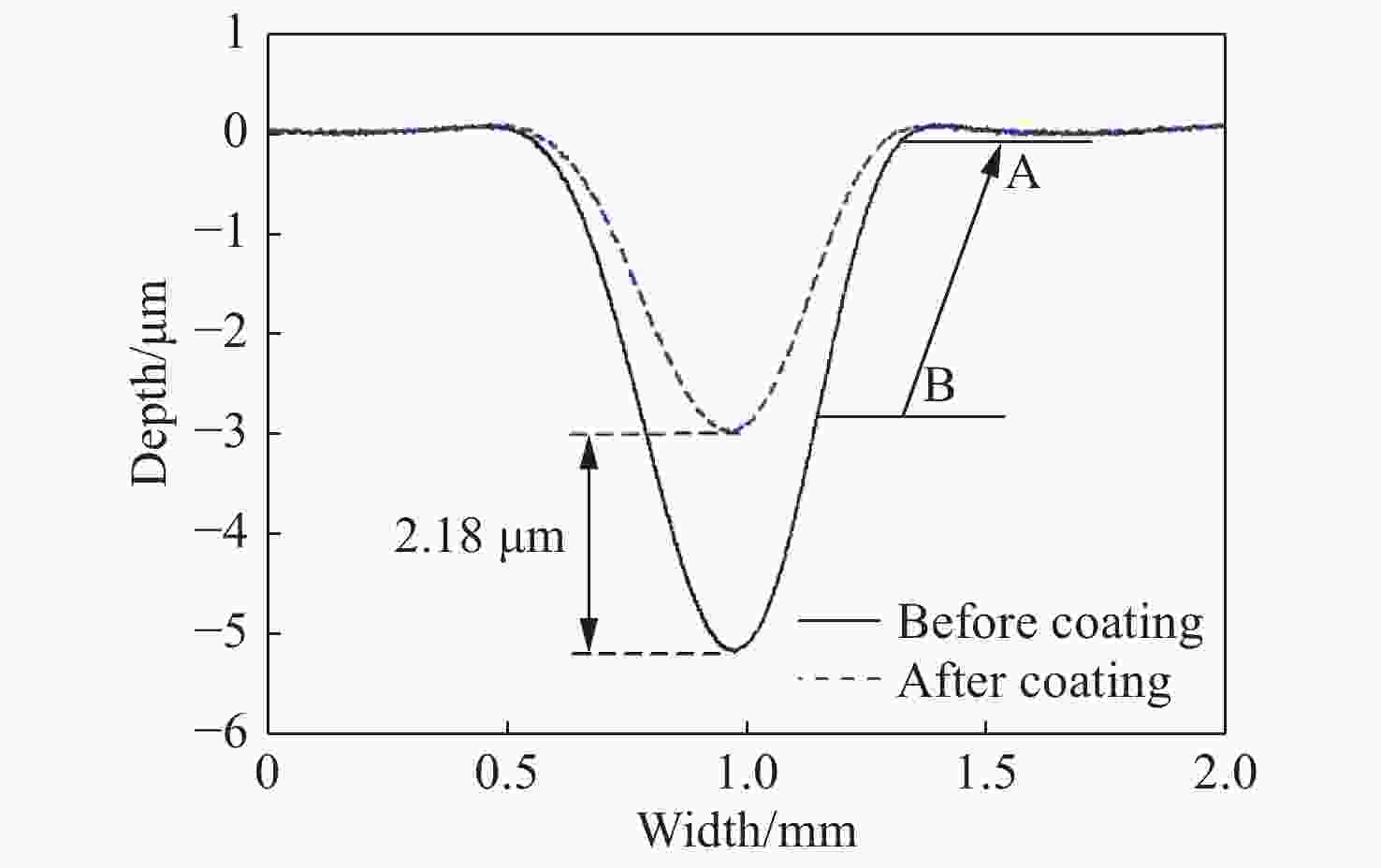

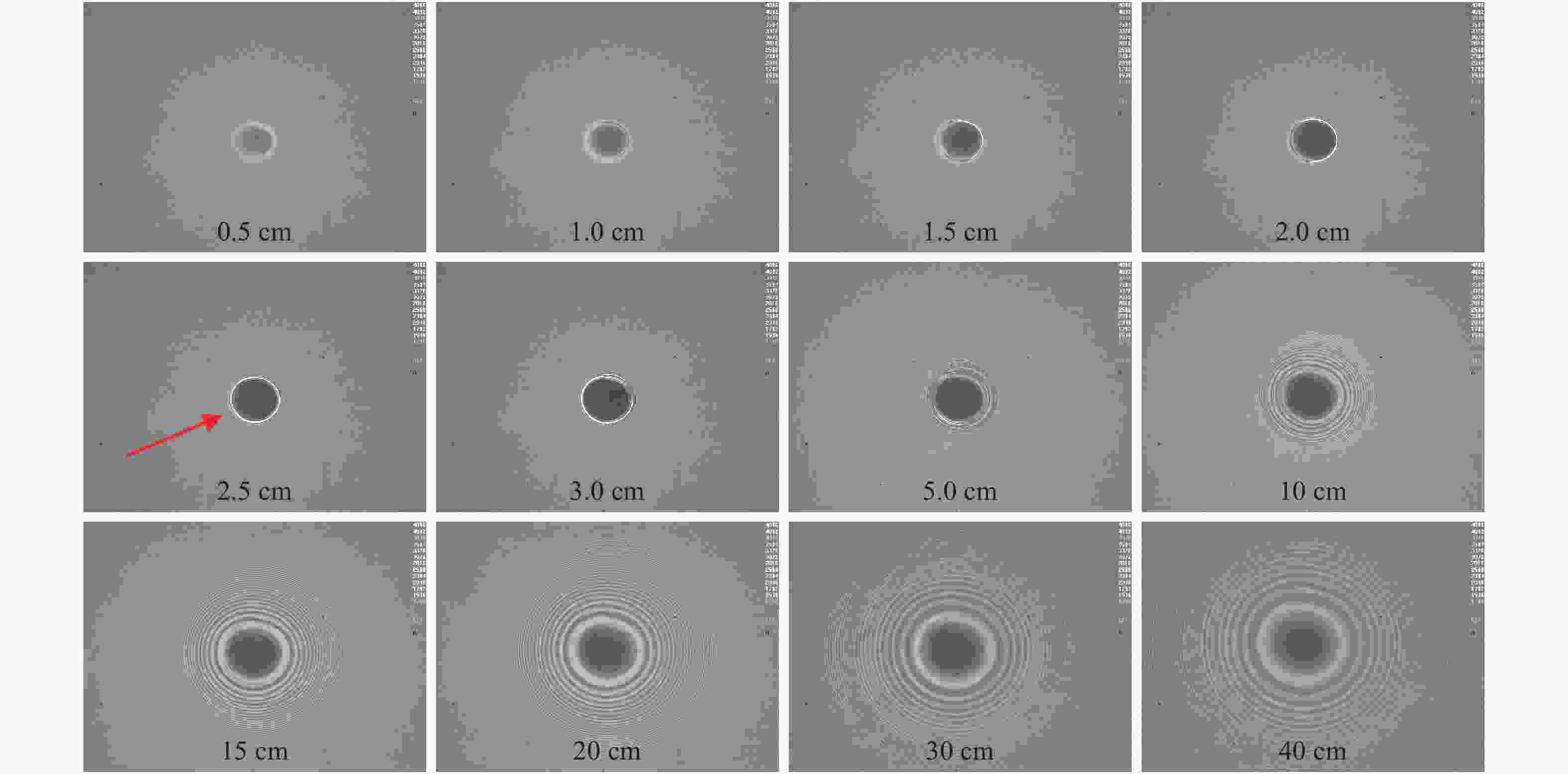

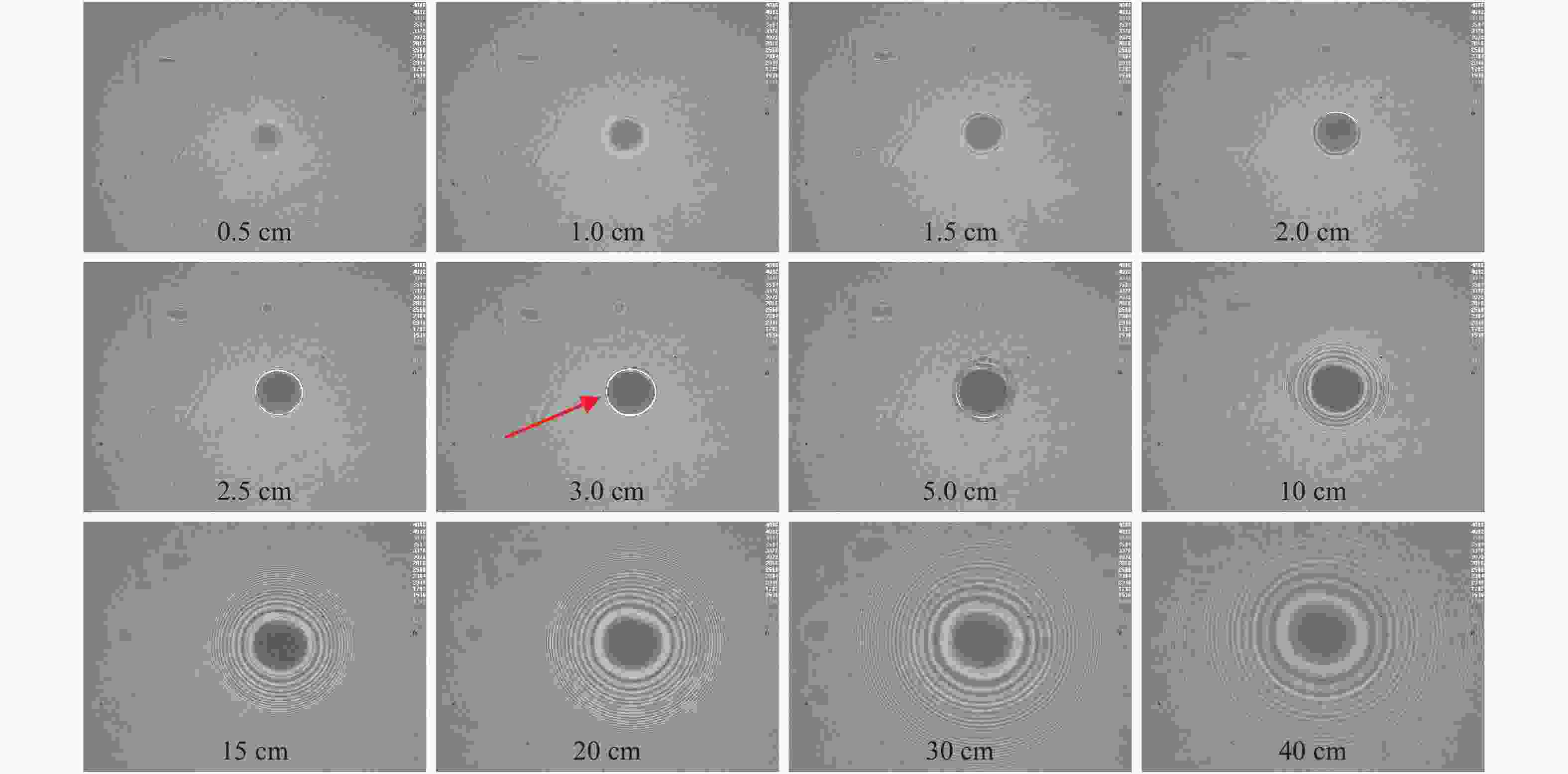

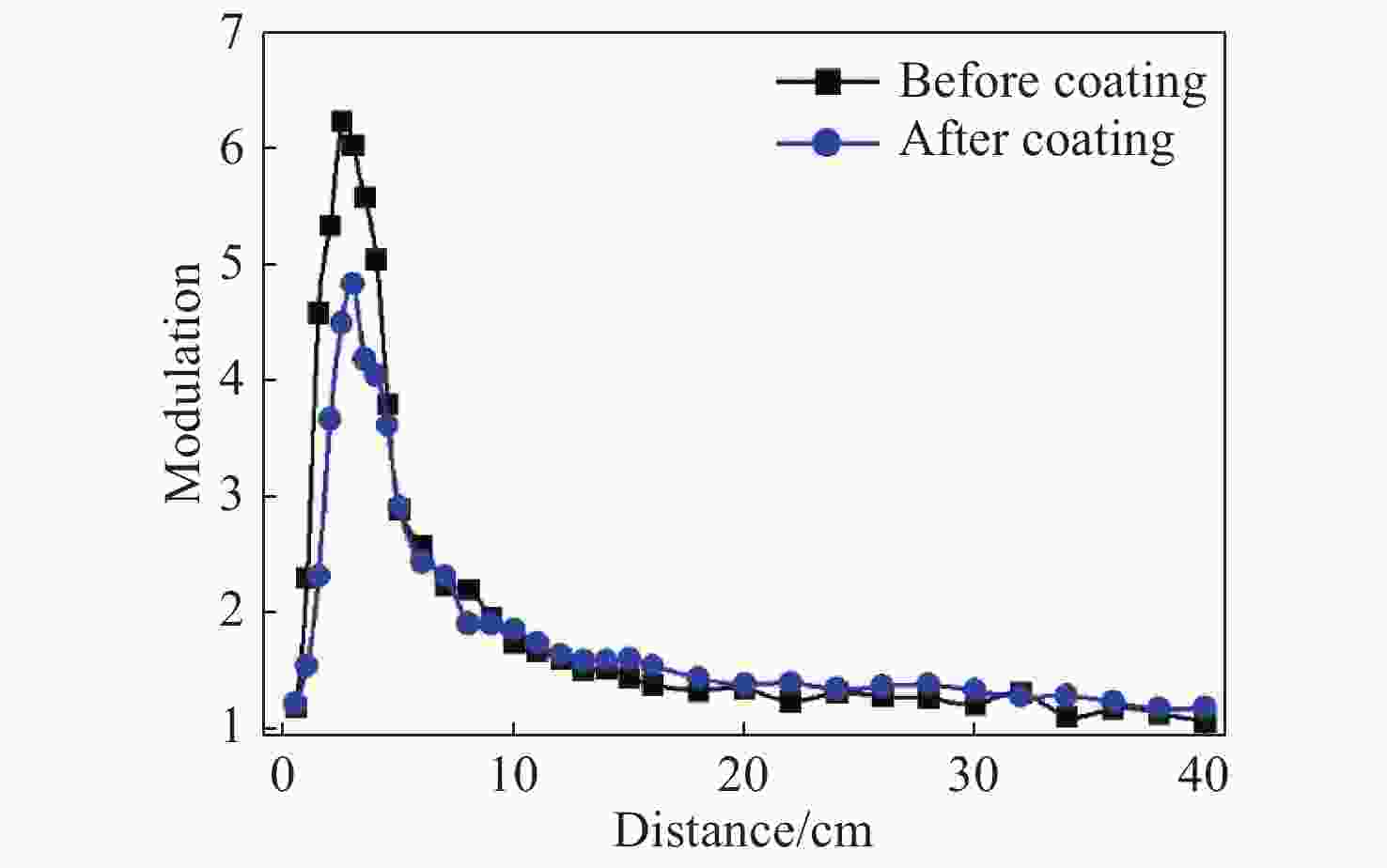

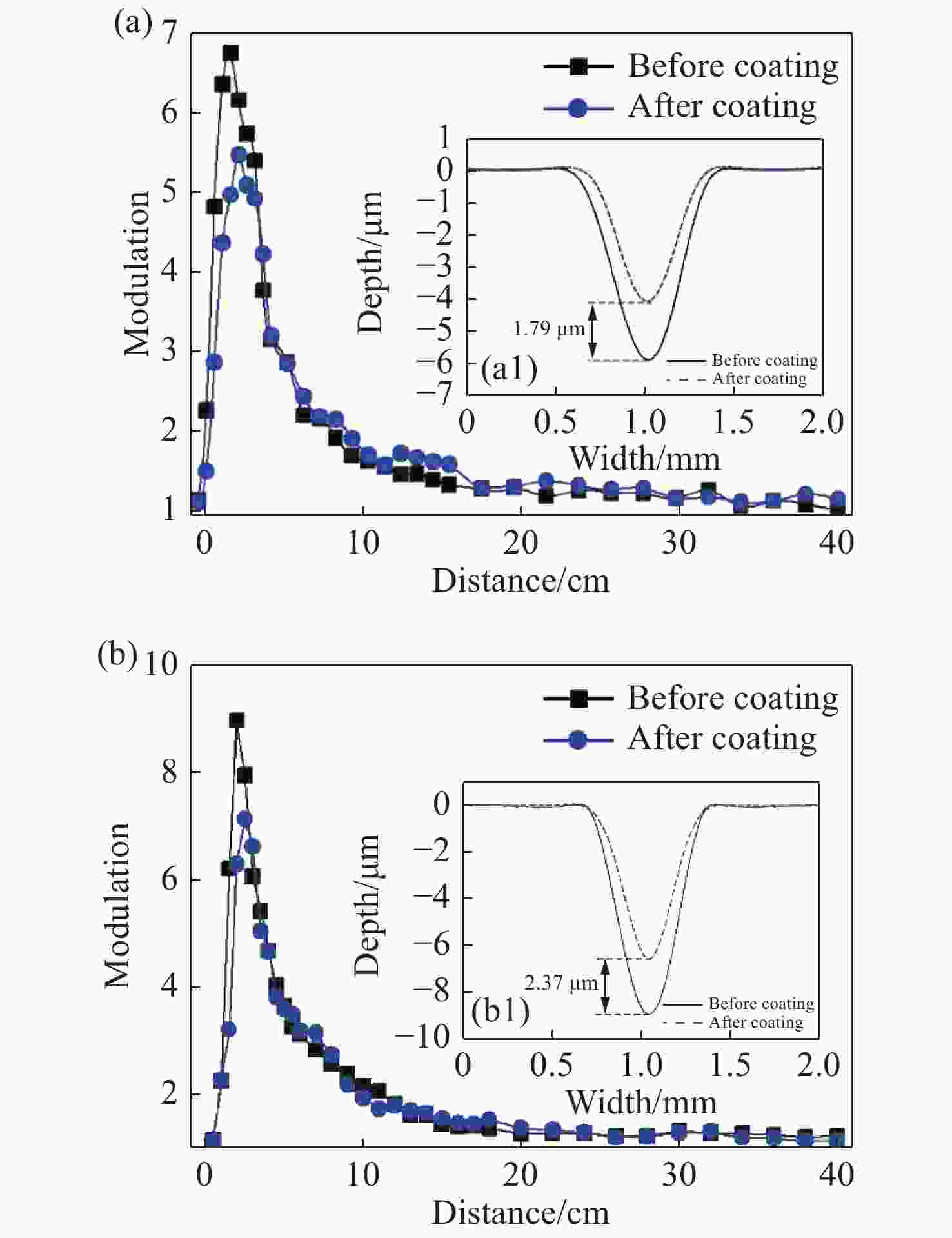

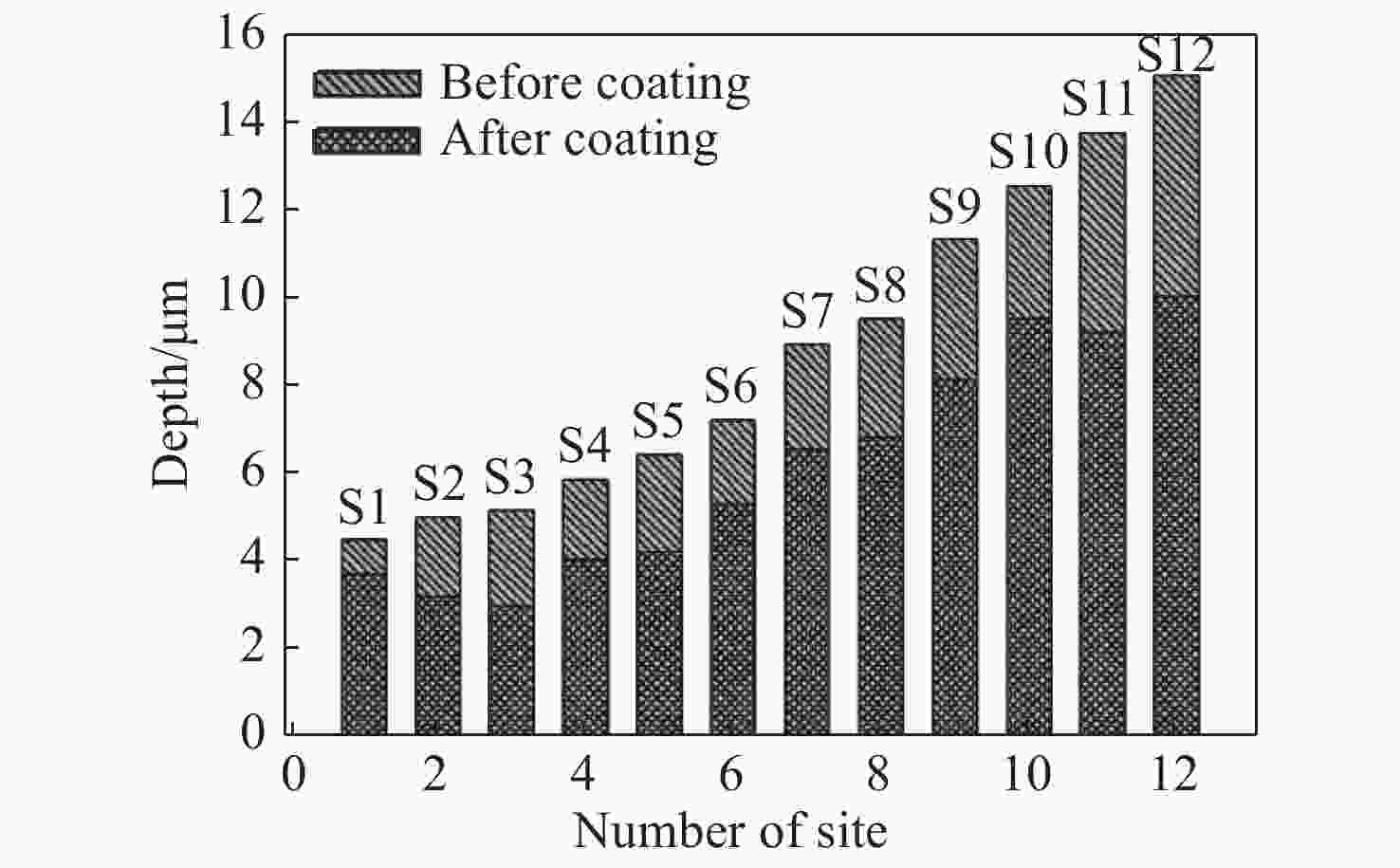

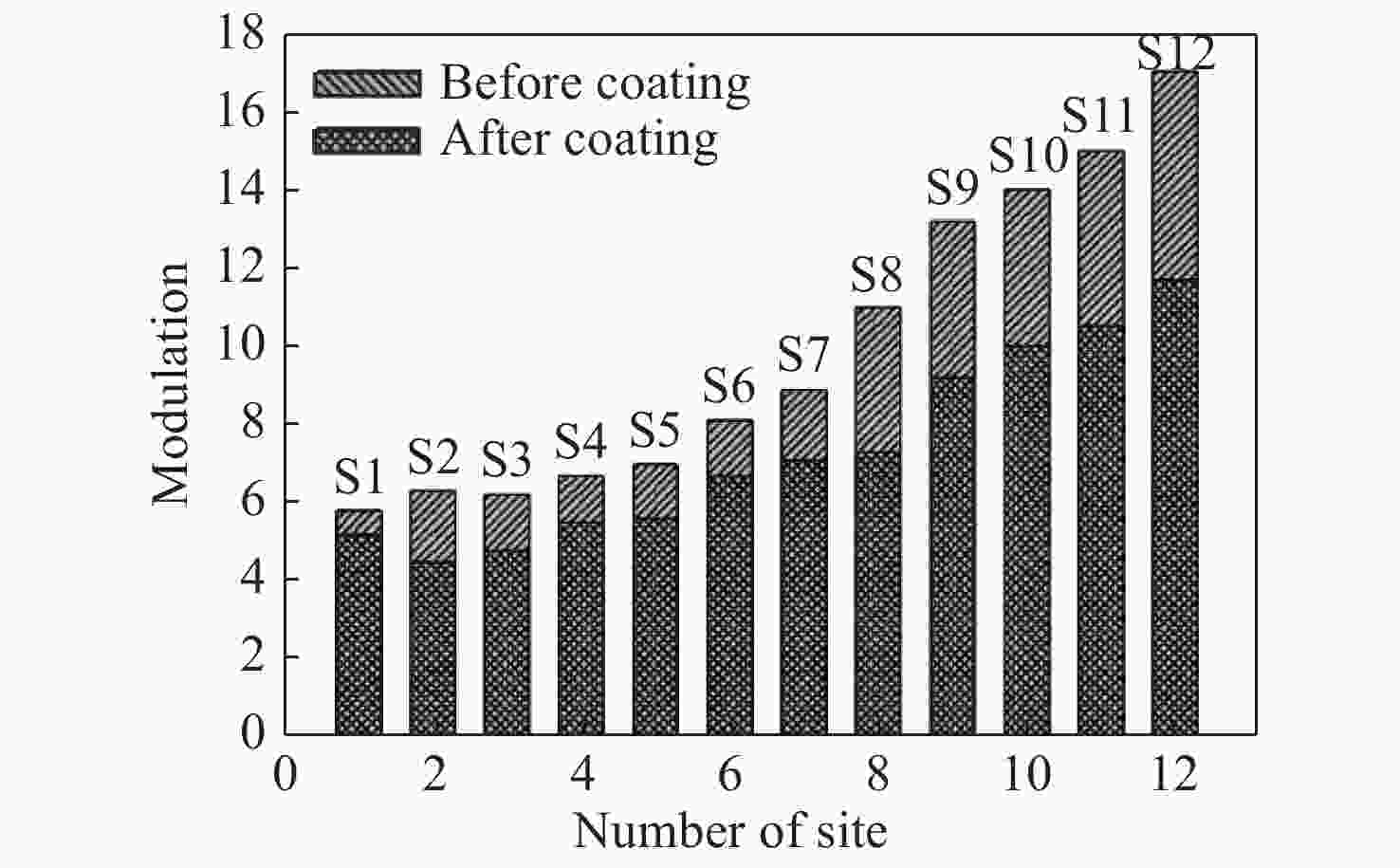

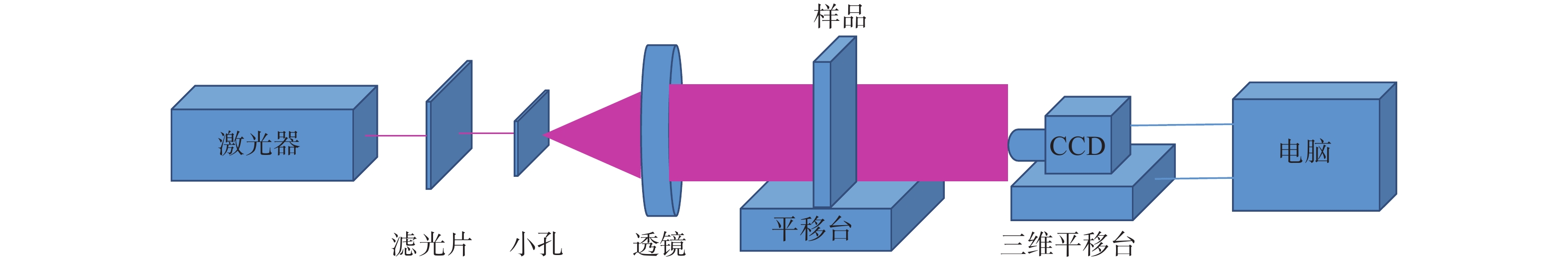

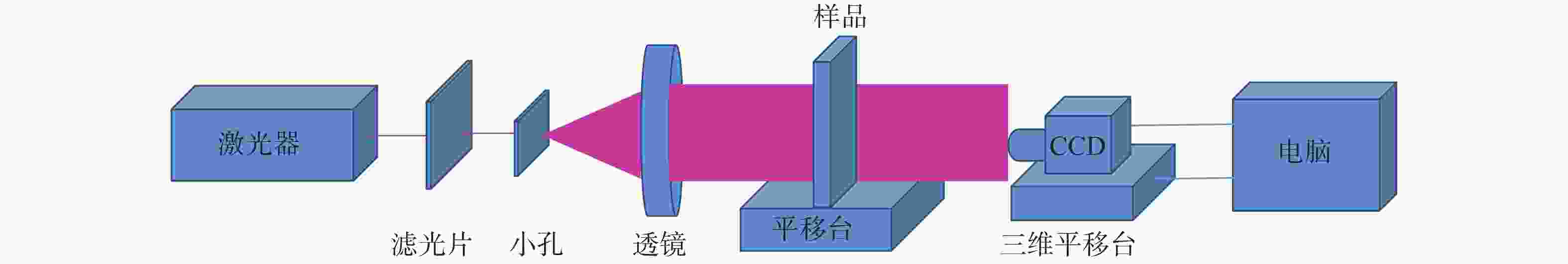

摘要: 针对CO2金宝搏188软件怎么用 修复熔石英表面损伤点后得到的修复点(简称损伤修复点)产生的光调制问题,重点研究损伤修复点在镀增透膜前后的形貌及光调制的变化规律,探讨修复点深度、宽度等形貌因素对SiO2胶体在修复点坑内沉积的影响,以及对光调制效应的影响。研究结果表明:胶体材料在损伤修复点坑内具有明显的富集效应,可有效改善损伤修复点的形貌尺寸,尤其是对深度的影响尤为明显。这虽然会导致损伤修复点镀膜后最大光调制位置的增大,但该最大光调制却远小于相应未镀膜损伤修复点引起的调制度。研究结果对进一步优化熔石英表面损伤点的修复工艺及光调制度控制提供参考。Abstract: In order to address the light modulation problem on repaired spots created after using a CO2 laser to repair the damage in fused silica surface, we research the change of the profile and the modulation of the repaired sites before and after coating them with antireflective film. The influence of the depth and width of the repaired site on the deposition of the colloid are discussed, with some attention also given to the influence of the modulation effect. The results indicate that the colloidal material significantly enriches the pits of a repair, which can effectively improve their topographic dimensions with regards to their depth. The maximum modulation locations of a repaired site will increase after being coated with the antireflective film. However, the maximum modulation caused by the repaired site is much smaller than that of the corresponding uncoated repaired point. The results of this study can provide a reference for further optimization of repair processes and light modulation regime control of the surface damage sites on fused silica.

-

Key words:

- fused silica /

- repaired site /

- light modulation /

- chemical coating /

- enrichment

-

表 1 损伤修复点镀膜前后参数与最大光调制度

Table 1. Parameters of the repaired site before and after coating vs. the maximum modulation

-

[1] 董家宁, 范杰, 王海珠, 等. 高反射光学薄膜金宝搏188软件怎么用 损伤研究进展[J]. 中国光学,2018,11(6):931-948. doi: 10.3788/co.20181106.0931DONG J N, FAN J, WANG H ZH, et al. Research progress in laser damage of high reflective optical thin films[J]. Chinese Optics, 2018, 11(6): 931-948. (in Chinese) doi: 10.3788/co.20181106.0931 [2] 王超, 张一杨, 张雅静, 等. 掺Yb3+石英玻璃中非桥氧空穴缺陷特性的研究[J]. 发光学报,2018,39(10):1359-1364. doi: 10.3788/fgxb20183910.1359WANG CH, ZHANG Y Y, ZHANG Y J, et al. Characteristics of non-bridging oxygen hole centers defects in Yb3+-doped silica glass[J]. Chinese Journal of Luminescence, 2018, 39(10): 1359-1364. (in Chinese) doi: 10.3788/fgxb20183910.1359 [3] BETTI R, HURRICANE O A. Inertial-confinement fusion with lasers[J]. Nature Physics, 2016, 12(5): 435-448. doi: 10.1038/nphys3736 [4] ZHENG W G, WEI X F, ZHU Q H, et al. Laser performance of the SG-III laser facility[J]. High Power Laser Science and Engineering, 2016, 4: e21. doi: 10.1017/hpl.2016.20 [5] 王玺, 李志明, 谢运涛, 等. 紫外准分子金宝搏188软件怎么用 损伤典型光学材料的特性分析[J]. 发光学报,2018,39(5):692-698. doi: 10.3788/fgxb20183905.0692WANG X, LI ZH M, XIE Y T, et al. Characteristics of typical optical materials damaged by ultraviolet excimer laser[J]. Chinese Journal of Luminescence, 2018, 39(5): 692-698. (in Chinese) doi: 10.3788/fgxb20183905.0692 [6] 田润妮, 邱荣, 蒋勇, 等. 熔石英亚表面球形杂质对入射光场的调制作用[J]. 光学学报,2015,35(4):0414003. doi: 10.3788/AOS201535.0414003TIAN R N, QIU R, JIANG Y, et al. Light field modulation induced by spherical inclusion in fused silica subsurface[J]. Acta Optica Sinica, 2015, 35(4): 0414003. (in Chinese) doi: 10.3788/AOS201535.0414003 [7] CHENG X B, ZHANG J L, DING T, et al. The effect of an electric field on the thermomechanical damage of nodular defects in dielectric multilayer coatings irradiated by nanosecond laser pulses[J]. Light:Science &Applications, 2013, 2(6): e80. [8] ZHU ZH W, CHENG X G, HUANG L J, et al. Light field intensification induced by nanoinclusions in optical thin-films[J]. Applied Surface Science, 2012, 258(12): 5126-5130. doi: 10.1016/j.apsusc.2012.01.145 [9] 孙晓艳, 雷泽民, 卢兴强, 等. 表面颗粒污染物诱导薄光学元件初始损伤的机理[J]. 物理学报,2014,63(13):134201.SUN X Y, LEI Z M, LU X Q, et al. Mechanism of original damage of thin optical components induced by surface particle contamination[J]. Acta Physica Sinica, 2014, 63(13): 134201. (in Chinese) [10] CHENG J, CHEN M J, LIAO W, et al. Influence of surface cracks on laser-induced damage resistance of brittle KH2PO4 crystal[J]. Optics Express, 2014, 22(23): 28740-28755. doi: 10.1364/OE.22.028740 [11] GÉNIN F Y, SALLEO A, PISTOR T V, et al. Role of light intensification by cracks in optical breakdown on surfaces[J]. Journal of the Optical Society of America A, 2001, 18(10): 2607-2616. doi: 10.1364/JOSAA.18.002607 [12] FEIGENBAUM E, ELHADJ S, MATTHEWS J M. Light scattering from laser induced pit ensembles on high power laser optics[J]. Optics Express, 2015, 23(8): 10589-10597. doi: 10.1364/OE.23.010589 [13] ZHENG Y, MA P, LI H B, et al. Studies on transmitted beam modulation effect from laser induced damage on fused silica optics[J]. Optics Express, 2013, 21(14): 16605-16614. doi: 10.1364/OE.21.016605 [14] HARRIS C D, SHEN N, RUBENCHIK A M, et al. Characterization of laser-induced plasmas associated with energetic laser cleaning of metal particles on fused silica surfaces[J]. Optics Letter, 2015, 40(22): 5212-5215. doi: 10.1364/OL.40.005212 [15] CORMONT P, COMBIS P, GALLAIS L, et al. Removal of scratches on fused silica optics by using a CO2 laser[J]. Optics Express, 2013, 21(23): 28272-28289. doi: 10.1364/OE.21.028272 [16] LIU CH M, YAN ZH H, YANG L, et al. Mitigation scratch on fused silica optics using CO2 laser[J]. Optica Applicata, 2016, 46(3): 387-397. [17] CORMONT P, BOURGEADE A, CAVARO S, et al. Relevance of carbon dioxide laser to remove scratches on large fused silica polished optics[J]. Advanced Engineering Materials, 2015, 17(3): 253-259. doi: 10.1002/adem.201400383 [18] JIANG Y, XIANG X, LIU CH M, et al. Two localized CO2 laser treatment methods for mitigation of UV damage growth in fused silica[J]. Chinese Physics B, 2012, 21(6): 064219. doi: 10.1088/1674-1056/21/6/064219 [19] JIANG Y, LIU CH M, LUO CH S, et al. Mitigation of laser damage growth in fused silica by using a non-evaporative technique[J]. Chinese Physics B, 2012, 21(5): 054216. doi: 10.1088/1674-1056/21/5/054216 [20] DOUALLE T, GALLAIS L, MONNERET S, et al. CO2 laser microprocessing for laser damage growth mitigation of fused silica optics[J]. Optical Engineering, 2016, 56(1): 011022. [21] 白阳, 张丽娟, 廖威, 等. 熔石英损伤修复坑下游光场调制的数值模拟与实验研究[J]. 物理学报,2016,65(2):024205. doi: 10.7498/aps.65.024205BAI Y, ZHANG L J, LIAO W, et al. Study of downstream light intensity modulation induced by mitigated damage pits of fused silica using numerical simulation and experimental measurements[J]. Acta Physica Sinica, 2016, 65(2): 024205. (in Chinese) doi: 10.7498/aps.65.024205 [22] GAO X, JIANG Y, QIU R, et al. Effect of the repaired damage morphology of fused silica on the modulation of incident laser[J]. Optical Materials, 2017, 64: 295-301. doi: 10.1016/j.optmat.2016.12.032 [23] LIAO W, LI B, ZHOU Q Y, et al. Optical modulation study of repaired damage morphologies of fused silica by scalar diffraction theory[J]. Optical Engineering, 2017, 56(1): 016113. doi: 10.1117/1.OE.56.1.016113 [24] 蒋勇, 向霞, 刘春明, 等. 熔石英表面损伤修复点上烧蚀碎片的分类与去除的研究[J]. 中国金宝搏188软件怎么用 ,2012,39(12):1203003. doi: 10.3788/CJL201239.1203003JIANG Y, XIANG X, LIU CH M, et al. Classification and elimination of ablation debris on the mitigated damage site in fused silica surface[J]. Chinese Journal of Lasers, 2012, 39(12): 1203003. (in Chinese) doi: 10.3788/CJL201239.1203003 [25] 蒋勇. 熔石英光学元件表面损伤修复的理论和实验研究[D]. 成都: 电子科技大学, 2012: 173-179.JIANG Y. Theoretical and experimental studies on surface damage repaire of fused silica optical components[D]. Chengdu: University of Electronic Science and Technology of China, 2012: 173-179. (in Chinese). [26] GUSS G, BASS I, DRAGGOO V, et al. Mitigation of growth of laser initiated surface damage in fused silica using a 4.6-micron wavelength laser[J]. Proceedings of SPIE, 2007, 6403: 64030M. [27] JIANG Y, MU X Y, QIU R, et al. Comparison of bare and sol-gel coated of mitigated site on fused silica[J]. Proceedings of SPIE, 2015, 9543: 95430M. doi: 10.1117/12.2177808 -

下载:

下载: