Multi-optical axis parallelism calibration of space photoelectric tracking and aiming system

-

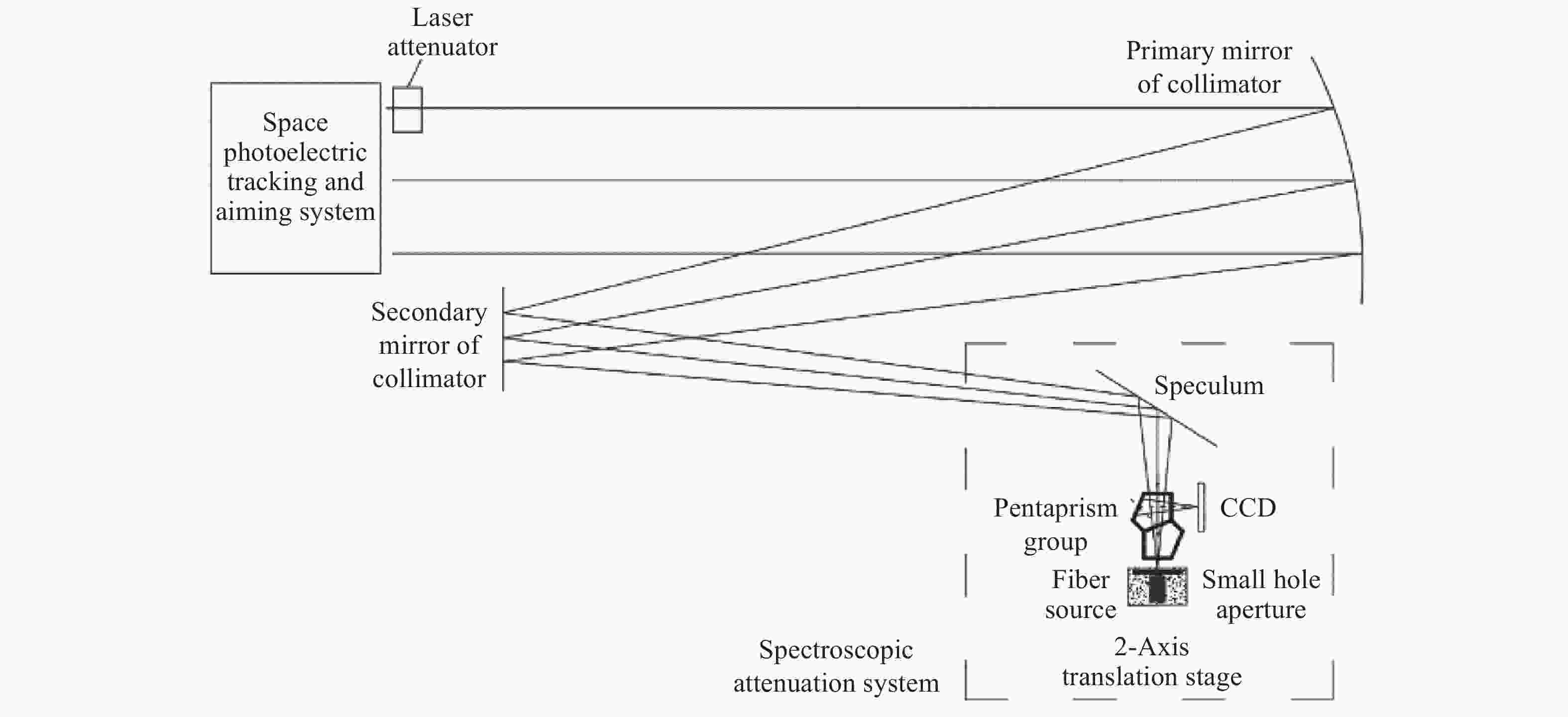

摘要: 为了解决空间光电跟瞄系统在真空环境下的多光轴标校问题,本文首先根据空间光电跟瞄系统的多光轴一致性检测精度要求,设计了一套多光轴标校系统。接着,对多光轴标校系统各子系统进行了详尽的误差分析,并给出了关键子系统的误差影响抑制方法。然后,对通信技术试验卫星三号的空间光电跟瞄系统进行了实验室环境与真空环境下的技术测试,分析了多光轴标校系统在两种测试环境下的误差来源以及测试精度,并给出了测试结果。最后,对多光轴标校系统进行了精度验证。最终结果表明:本文设计的多光轴标校系统在实验室测试环境下的标校精度为0.998″,收发平行度标定误差为1.165″;在真空测试环境下的标校精度为1.219″,收发平行度标定误差为1.359″,完全满足空间光电跟瞄系统1.5″的多光轴检测精度要求,为相关工程应用提供了技术支持。Abstract: To achieve multi-optical axis calibration of the space photoelectric tracking and aiming system in a vacuum, this paper first designed a set of multi-axis calibration systems according to the accuracy requirements for multi-axis consistency detection of the space photoelectric tracking and aiming system. Then, a detailed error analysis of each subsystem of the multi-axis calibration system was conducted, and the methods to restrain the influence of error in the key subsystem were given. After that, the technical tests of the space photoelectric tracking and aiming system of the Communications Technology Experiment Satellite 3 were implemented in laboratory and vacuum environments, and the error sources and test accuracy of the multi-axis calibration system in the two test environments were analyzed and the test results were given. Finally, the accuracy of the multi-axis calibration system was verified. The final results show that the calibration accuracy of the multi-axis calibration system in this paper is 0.998" in the laboratory test environment, and the calibration error of the parallelism of transmitter and receiver is 1.165"; the calibration accuracy is 1.219" in the vacuum test environment, and the calibration error of parallelism of transmitter and receiver is 1.359". These results fully meet the 1.5" multi-optical axis detection accuracy requirements of the space photoelectric tracking system, and provide support for research in related engineering applications.

-

表 1 分光衰减系统的测试设备

Table 1. Test equipment of the spectroscopic attenuation system

仪器 指标要求 干涉仪 PV测量精度优于λ/30(@632.8 nm) 标准球面镜 Φ100 mm口径,F#7和F#11标准头 调整机构 可实现平移和倾斜调整 表 2 实验室环境下的测试结果

Table 2. Test results in a laboratory environment (″)

测试环境 测试结果 水平方向 竖直方向 实验室环境 43.68 37.41 表 3 空间光电跟瞄系统的真空环境测试结果

Table 3. Test results of space photoelectric tracking and aiming system in a vacuum environment (″)

测试环境 测试结果 水平方向 竖直方向 真空环境 48.37 36.26 表 4 反置后的跟瞄系统实验室环境与真空环境收发平行度测试数据对比

Table 4. Comparison of parallelism test results of reversed placed tracking and aiming system in the laboratory environment and the vacuum environment (Unit: ″)

测试环境 测试结果 水平方向 竖直方向 实验室环境 −43.12 −36.98 真空环境 −47.96 −36.12 表 5 同类多光轴平行性标校设备的标校精度统计表

Table 5. Calibration accuracy statistics of similar multi-axis parallelism calibration equipment (Unit: ″)

主要设计者 设计年份 标校精度 徐丹慧 2020 5 黄富瑜 2019 27.68 杨雪 2019 8.87 王若帆 2018 6.19 谢国兵 2018 5 纪小辉 2018 10.31 易瑔 2018 2.92 -

[1] 王卫兵, 王挺峰, 郭劲. 基于星载光电成像跟踪测距的空间目标定轨[J]. 光学 精密工程,2015,23(2):528-539. doi: 10.3788/OPE.20152302.0528WANG W B, WANG T F, GUO J. Orbit determination for space target based on opto-electrical imaging, tracking and ranging on satellite[J]. Optics and Precision Engineering, 2015, 23(2): 528-539. (in Chinese) doi: 10.3788/OPE.20152302.0528 [2] 李治国, 高立民, 张博妮, 等. 空间光电跟踪系统动量平衡设计与试验[J]. 光学 精密工程,2013,21(1):62-68. doi: 10.3788/OPE.20132101.0062LI ZH G, GAO L M, ZHANG B N, et al. Design and experiment of momentum balance wheels for optoelectric tracking gimbals[J]. Optics and Precision Engineering, 2013, 21(1): 62-68. (in Chinese) doi: 10.3788/OPE.20132101.0062 [3] 徐丹慧, 唐霞辉, 方国明, 等. 基于干涉条纹的光轴平行性校准方法[J]. 光学学报,2020,40(17):1712005. doi: 10.3788/AOS202040.1712005XU D H, TANG X H, FANG G M, et al. Method for calibration of optical axis parallelism based on interference fringes[J]. Acta Optica Sinica, 2020, 40(17): 1712005. (in Chinese) doi: 10.3788/AOS202040.1712005 [4] 谢国兵, 薛永刚, 晁格平, 等. 基于LABVIEW的多光轴平行性测试方法[J]. 应用光学,2018,39(6):856-861.XIE G B, XUE Y G, CHAO G P, et al. Test method of multi-axis parallelism based on LABVIEW[J]. Journal of Applied Optics, 2018, 39(6): 856-861. (in Chinese) [5] 宋俊儒, 邢辉, 穆生博, 等. 航空红外相机的装调[J]. 光学 精密工程,2015,23(8):2125-2133. doi: 10.3788/OPE.20152308.2125SONG J R, XING H, MU SH B, et al. Alignment of aerial multi-angle infrared camera[J]. Optics and Precision Engineering, 2015, 23(8): 2125-2133. (in Chinese) doi: 10.3788/OPE.20152308.2125 [6] 叶露, 武晓阳, 聂真威. 强 与红外传感器光轴平行性测量仪器的研制[J]. 中国光学与应用光学,2008,1(1):100-104.YE L, WU X Y, NIE ZH W. Development of measuring instrument of optical-axis parallelism for strong laser and infrared sensor[J]. Chinese Journal of Optics and Applied Optics, 2008, 1(1): 100-104. (in Chinese) [7] 黄富瑜, 李刚, 史云胜, 等. 多光谱多光轴平行性检测方案设计与误差分析[J]. 光电工程,2019,46(2):9-17.HUANG F Y, LI G, SHI Y SH, et al. Design and error analysis of multi-spectral and multi-axis parallelism testing scheme[J]. Opto-Electronic Engineering, 2019, 46(2): 9-17. (in Chinese) [8] 纪小辉, 孔巍. 多光谱共孔径无穷远目标器设计[J]. 应用光学,2018,39(3):339-342.JI X H, KONG W. Design of multi-spectral common aperture infinity collimator[J]. Journal of Applied Optics, 2018, 39(3): 339-342. (in Chinese) [9] 易瑔, 王林森, 杨建昌, 等. 观瞄系统光轴平行性原位检测的光学系统设计[J]. 光学技术,2018,44(1):113-116.YI Q, WANG L S, YANG J CH, et al. Design of parallelism of optical axis in-situ detection's optical system of observing and aiming system[J]. Optical Technique, 2018, 44(1): 113-116. (in Chinese) [10] 杨雪, 陈文红, 张玺, 等. 宽光谱光电系统多光轴平行性工程化测试方法研究[J]. 与红外,2019,49(8):978-982. doi: 10.3969/j.issn.1001-5078.2019.08.012YANG X, CHEN W H, ZHANG X, et al. A method for multi-axial parallelism measurement of a multi-band optoelectronic system in engineering[J]. Laser &Infrared, 2019, 49(8): 978-982. (in Chinese) doi: 10.3969/j.issn.1001-5078.2019.08.012 [11] 贾文武, 刘培正, 唐自力, 等. 靶场适用的光电经纬仪光轴平行性检测[J]. 光学 精密工程,2020,28(8):1670-1677.JIA W W, LIU P ZH, TANG Z L, et al. Detection method for optical-axis parallelism of photoelectric theodolite in range[J]. Optics and Precision Engineering, 2020, 28(8): 1670-1677. (in Chinese) [12] JAKLITSCH J J, EHART A F, JONES D A, et al.. Gyroscopic system for boresighting equipment: USA, 7065888B2[P]. 2006-06-27. [13] JAKLITSCH J J, PATURZO V A. Non line of sight boresight based on inertial measurement technology[C]. Proceedings of 2003 IEEE Systems Readiness Technology Conference, IEEE, 2003: 527-533. [14] CARL ZEISS. Calibration and alignment[EB/OL].[2018-08-01]. www.zeiss.com/optronics. [15] SCHILL REGLERTEKNIK. Aligner 308 ship alignment system[EB/OL].[2018-08-01]. www.schill.se. [16] METRONOR. Next generation boresight system[EB/OL].[2018-08-01]. www.metronor.com/military/. [17] CI SYSTEMS. Advanced Weapon Boresight System (AWBS)[EB/OL].[2020-05-18]. https://www.ci-systems.com/awbs. [18] CABIB D, RAHAV A, BARAK T. Broad-band optical test bench (OPTISHOP) to measure MTF and transmittance of visible and IR optical components[J]. Proceedings of SPIE, 2007, 6543: 654311. doi: 10.1117/12.719170 [19] 张勇, 吴浩, 马飒飒. 大间距轴线一致性检测技术进展与分析[J]. 光电工程,2019,46(2):73-81.ZHANG Y, WU H, MA S S. Development and analysis of large spacing axis consistency detection technology[J]. Opto-Electronic Engineering, 2019, 46(2): 73-81. (in Chinese) [20] 凌军, 刘秉琦, 赵熙林. 几种光轴平行性测试方法的比较与探讨[J]. 应用光学,2003,24(1):43-45.LING J, LIU B Q, ZHAO X L. The comparison and discussion of several testing methods about optical-axis parallelism[J]. Journal of Applied Optics, 2003, 24(1): 43-45. (in Chinese) [21] 陈志斌, 李义照, 王呈阳, 等. 测距机光斑及其光轴平行性检测方法研究[J]. 红外与 工程,2007,36(S1):529-532.CHEN ZH B, LI Y ZH, WANG CH Y, et al. Laser spot and it's optic axis collimation detection method for laser range finder[J]. Infrared and Laser Engineering, 2007, 36(S1): 529-532. (in Chinese) [22] 陈志斌, 肖文健, 马东玺, 等. 大间距多光轴一致性野外在线检测方法[J]. 光学学报,2017,37(1):0112006. doi: 10.3788/AOS201737.0112006CHEN ZH B, XIAO W J, MA D X, et al. A method for large distance multi-optical axis parallelism online detection[J]. Acta Optica Sinica, 2017, 37(1): 0112006. (in Chinese) doi: 10.3788/AOS201737.0112006 [23] 张磊, 邱伟, 张凯. 基于双五棱镜组件的大间距光轴平行性检测方法[J]. 红外与 工程,2018,47(7):0717005. doi: 10.3788/IRLA201847.0717005ZHANG L, QIU W, ZHANG K. Detection method of large space optical axis parallelism based on double pentaprism components[J]. Infrared and Laser Engineering, 2018, 47(7): 0717005. (in Chinese) doi: 10.3788/IRLA201847.0717005 [24] 张勇, 吴浩, 牛刚. 基于非合作目标图像处理技术的大间距轴线一致性检测方法[J]. 与光电子学进展,2019,56(5):051203.ZHANG Y, WU H, NIU G. Consistency detection method for large spacing axis based on non-cooperative target image processing technology[J]. Laser &Optoelectronics Progress, 2019, 56(5): 051203. (in Chinese) [25] 王春艳, 姜会林, 王陆, 等. 用于火控动态性能测试的多光轴光学系统[J]. 兵工学报,2011,32(6):746-751.WANG CH Y, JIANG H L, WANG L, et al. The multi-axial optical system study for fire control dynamic performance testing[J]. Acta Armamentarii, 2011, 32(6): 746-751. (in Chinese) [26] 王若帆, 张国玉, 曹秒, 等. 红外脉冲 测距仪发收光轴一致性测试方法研究[J]. 长春理工大学学报(自然科学版),2018,41(1):60-62.WANG R F, ZHANG G Y, CAO M, et al. Research on measurement method of optical coherence of transmitting and receiving infrared pulse laser range finder[J]. Journal of Changchun University of Science and Technology (Natural Science Edition) , 2018, 41(1): 60-62. (in Chinese) [27] 刘亚辰, 张新磊, 高扬, 等. 光电跟踪瞄准系统的多光轴平行度校准方法研究[J]. 宇航计测技术,2015,35(4):5-8, 23. doi: 10.3969/j.issn.1000-7202.2015.04.005LIU Y CH, ZHANG X L, GAO Y, et al. Study for multi-spectral axes parallelism calibration of photoelectric tracking and aiming system[J]. Journal of Astronautic Metrology and Measurement, 2015, 35(4): 5-8, 23. (in Chinese) doi: 10.3969/j.issn.1000-7202.2015.04.005 [28] 黄静, 刘朝晖, 折文集, 等. 室内多波段光轴一致性测试系统的设计[J]. 应用光学,2007,28(5):663-666.HUANG J, LIU ZH H, SHE W J, et al. Design of lab test system for boresight of multi-channel optical axes[J]. Journal of Applied Optics, 2007, 28(5): 663-666. (in Chinese) -

下载:

下载: