-

摘要: 微细铣刀在主轴上存在装夹偏角时,会加剧刀刃磨损,降低刀具使用寿命。为了精确观测微细铣刀在机倾斜状态,提出了基于景深的微细铣刀三维位姿重建方法。利用金宝搏188软件怎么用 同轴数字全息实验装置得到微细铣刀全息图,并通过菲涅尔再现算法获得再现像。在再现像中提取刀具边缘点作为关键点,采用小波变换局部方差算子求出关键点的聚焦程度,确定铣刀对应的轴向位置。利用最小二乘法对关键点拟合修正重建误差,实现微细铣刀的三维位姿重建。实验结果表明,基于景深的微细铣刀三维位姿重建方法获得的微细铣刀重建误差优于0.1°。该方法能够精确测量微细铣刀三维位姿,可为后续的微细铣刀装夹精度修正提供参考依据。Abstract: When a micro-milling tool has a clamping angle on its spindle, the wear of the tool edge will accelerate and shorten the tool’s lifespan. In order to accurately observe the inclination state of the micro-milling tool on the machine, a three-dimensional pose reconstruction method based on the depth of field of a micro-milling tool is proposed. The laser coaxial digital holographic experimental device is used to obtain the micro-milling tool hologram, and the reconstruction image is obtained through the Fresnel reconstruction algorithm. The tool edge points are extracted as the key points in the reconstruction image, the wavelet transform local variance operator is used to obtain the degree of focus of the key points, and then the axial position corresponding to the milling tool is determined. The least square method is used to fit the key points and correct the reconstruction error, from which the three-dimensional pose reconstruction of the micro-milling tool is realized. The experimental results show that the reconstruction error of the micro-milling tool obtained by the three-dimensional pose reconstruction method is better than 0.1°. This method can accurately measure a three-dimensional pose of a micro-milling tool, which can provide a reference for the subsequent correction of micro-milling tool clamping accuracy.

-

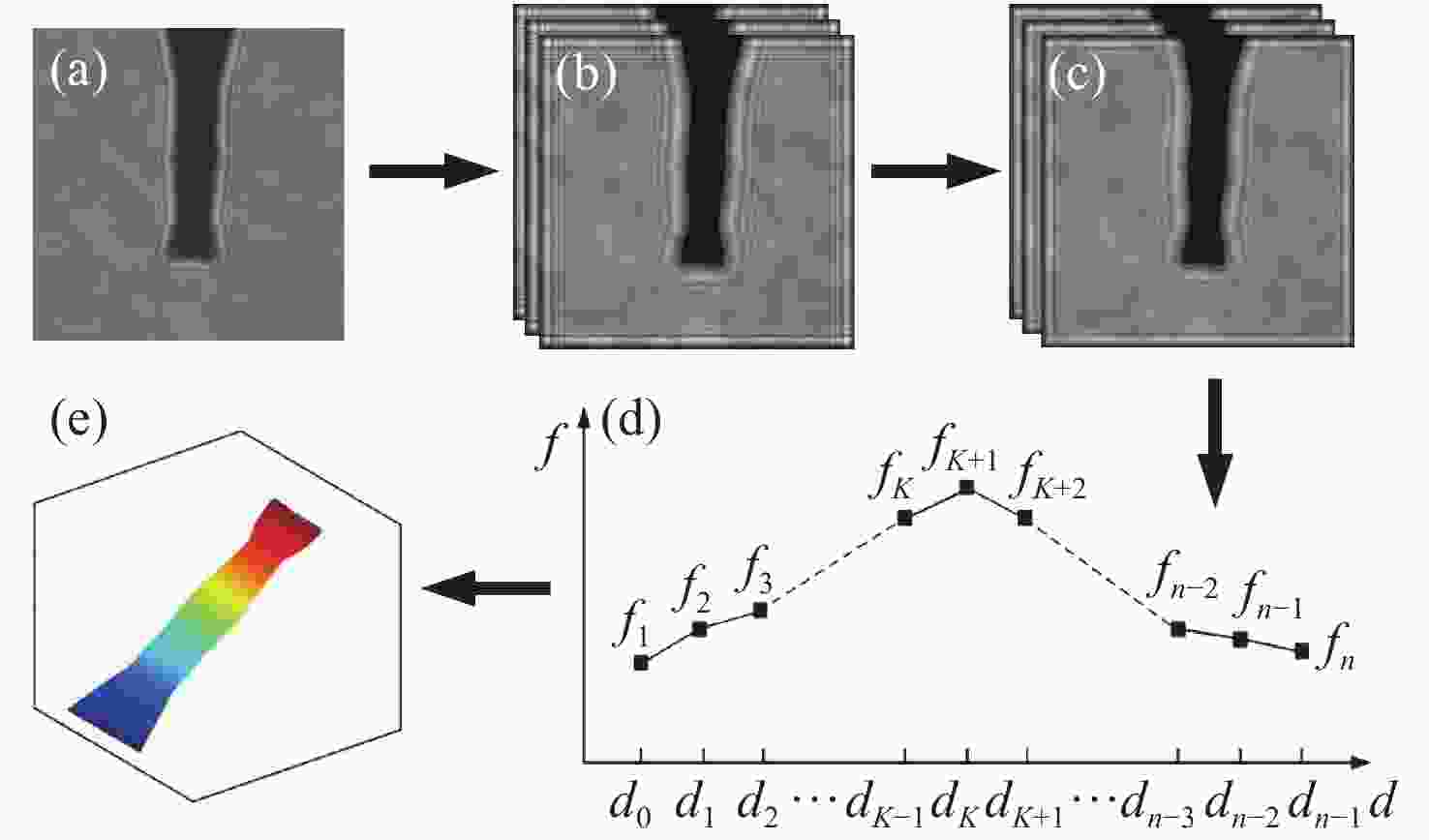

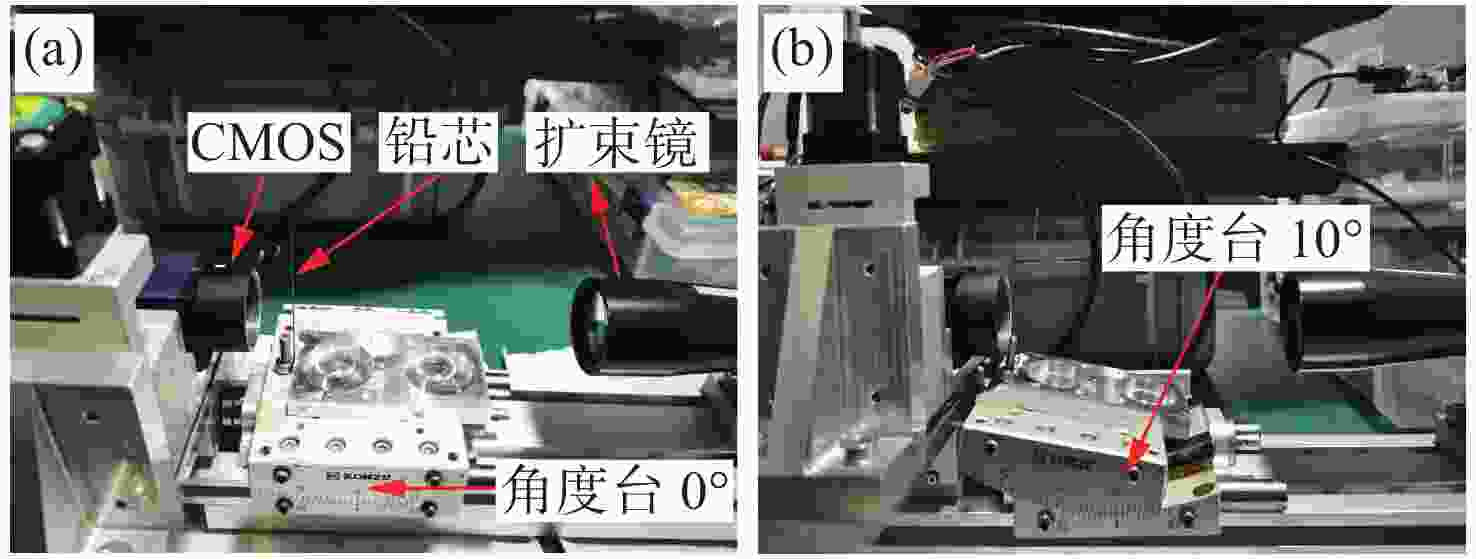

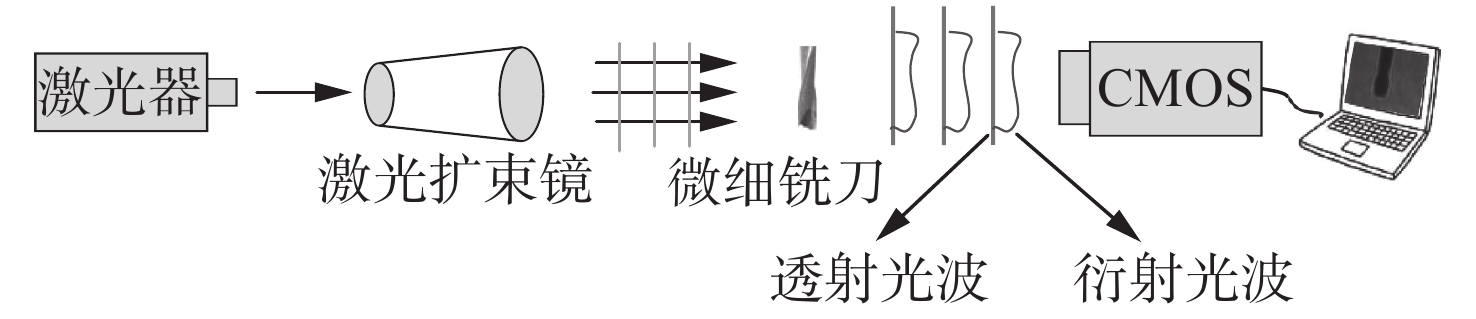

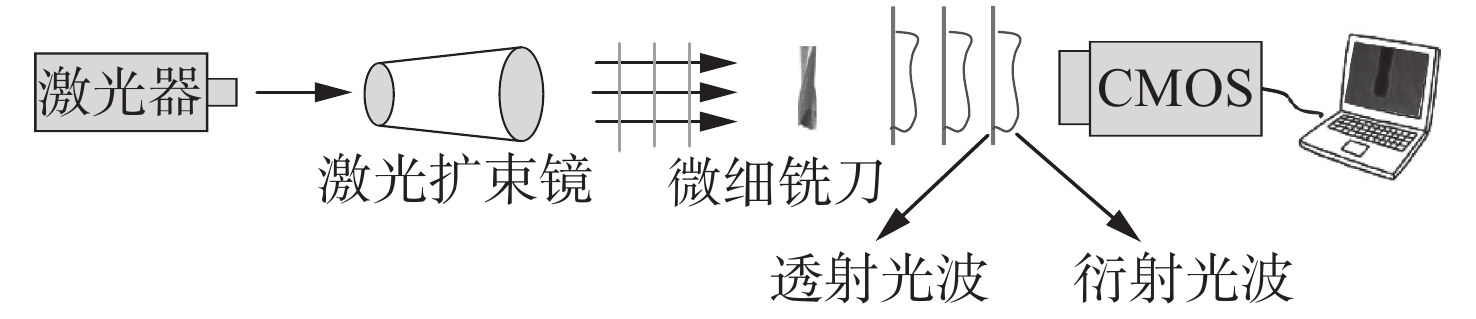

图 3 刀具三维位姿重构流程图。(a)刀具全息图;(b) n张再现像;(c)滤波后的n张再现像;(d)点(i, j)的最佳再现距离;(e)刀具三维位姿示意图

Figure 3. Flow diagram of three-dimensional pose reconstruction of the tool. (a) Tool hologram; (b) reconstruction images; (c) reconstruction images after filtering; (d) best reconstruction distance for point (i, j); (e) schematic diagram of the tool’s three-dimensional pose

图 8 (a)小波变换局部方差算子对应的低频点的聚焦评价曲线; (b)小波变换局部方差算子对应的边缘点的聚焦评价曲线; (c)局部灰度方差算子对应的低频点聚焦评价曲线; (d)局部灰度方差算子对应的边缘点聚焦评价曲线

Figure 8. (a) Focus evaluation curve of low frequency points corresponding to the local variance operator of the wavelet transform; (b) focus evaluation curve of the edge points corresponding to the local variance operator of the wavelet transform; (c) focus evaluation curve of the low frequency points corresponding to the local gray-scale variance operator; (d) focus evaluation curve of the edge points corresponding to the local gray-scale variance operator

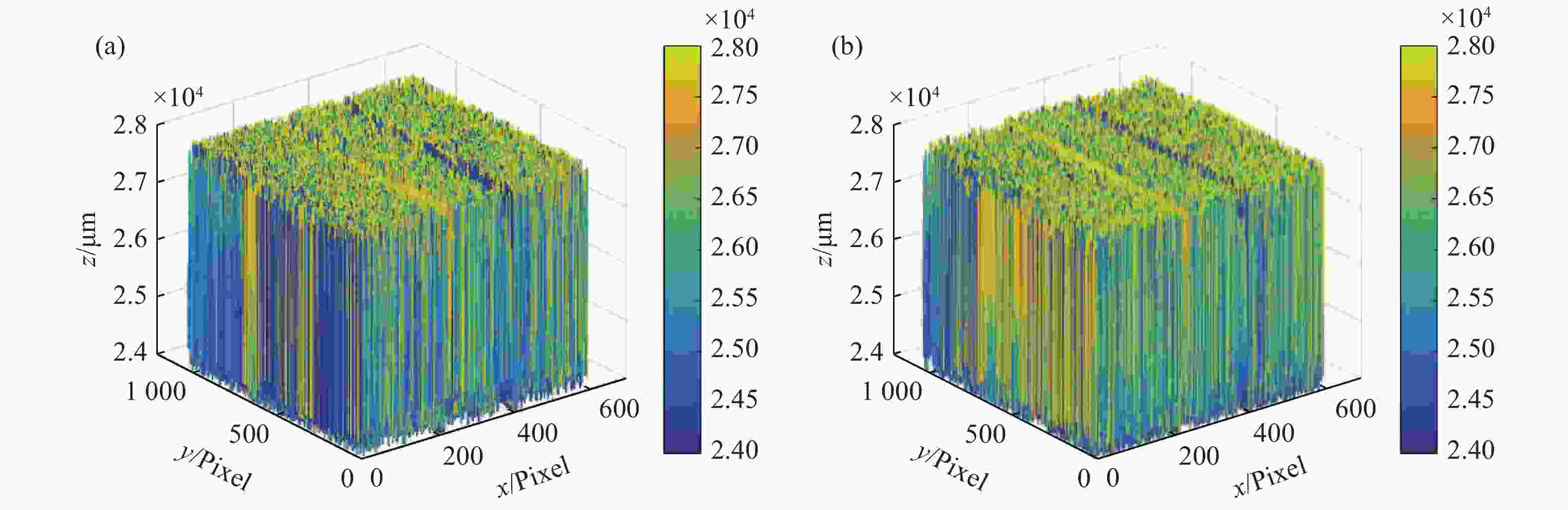

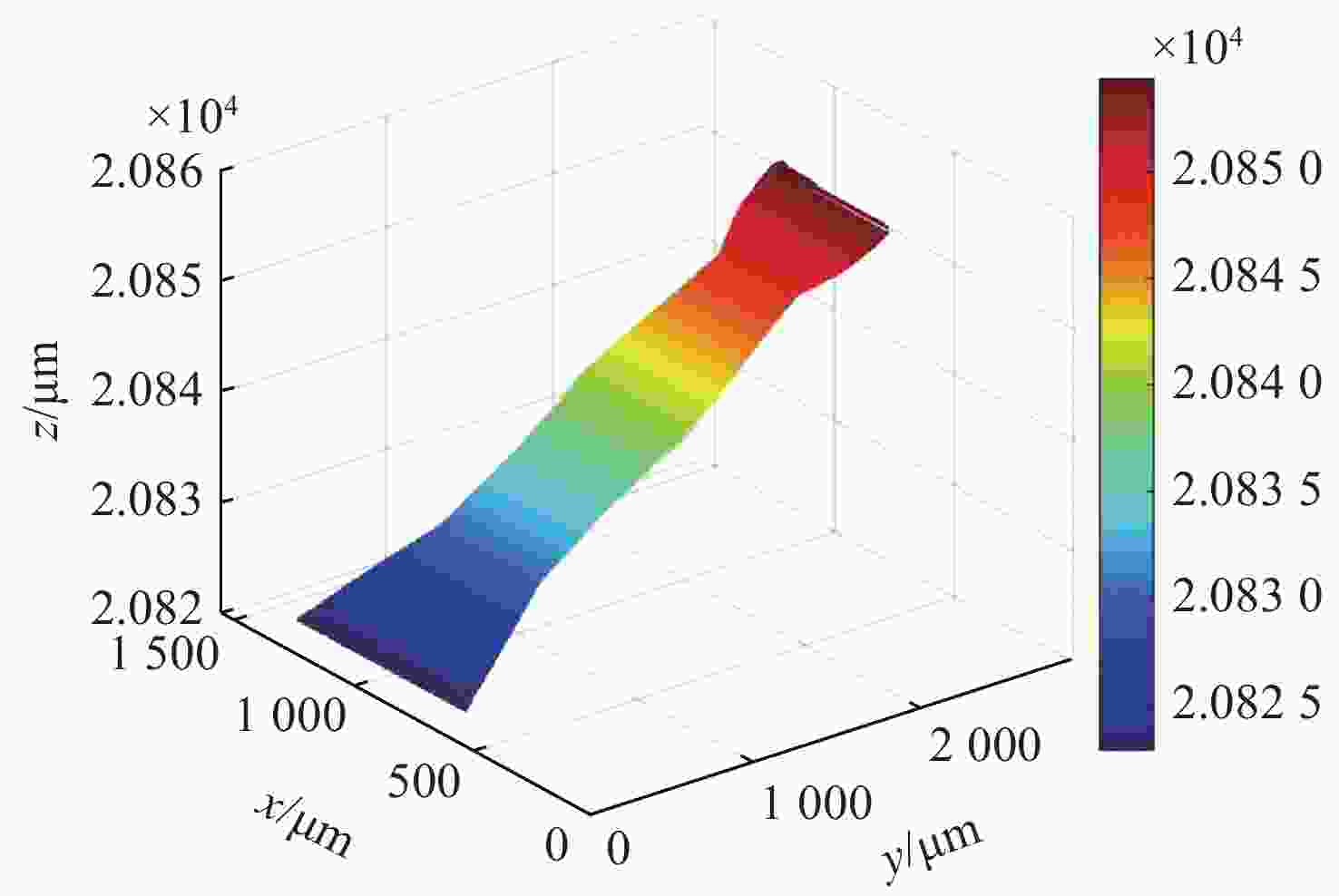

图 9 铅芯的三维重建结果。(a)小波变换局部方差算子的三维重建结果;(b)局部灰度方差算子的三维重建结果

Figure 9. Three-dimensional reconstruction results of lead core. (a) Three-dimensional reconstruction results calculated by local variance operator of the wavelet transform; (b) three-dimensional reconstruction results calculated by local gray-scale variance operator

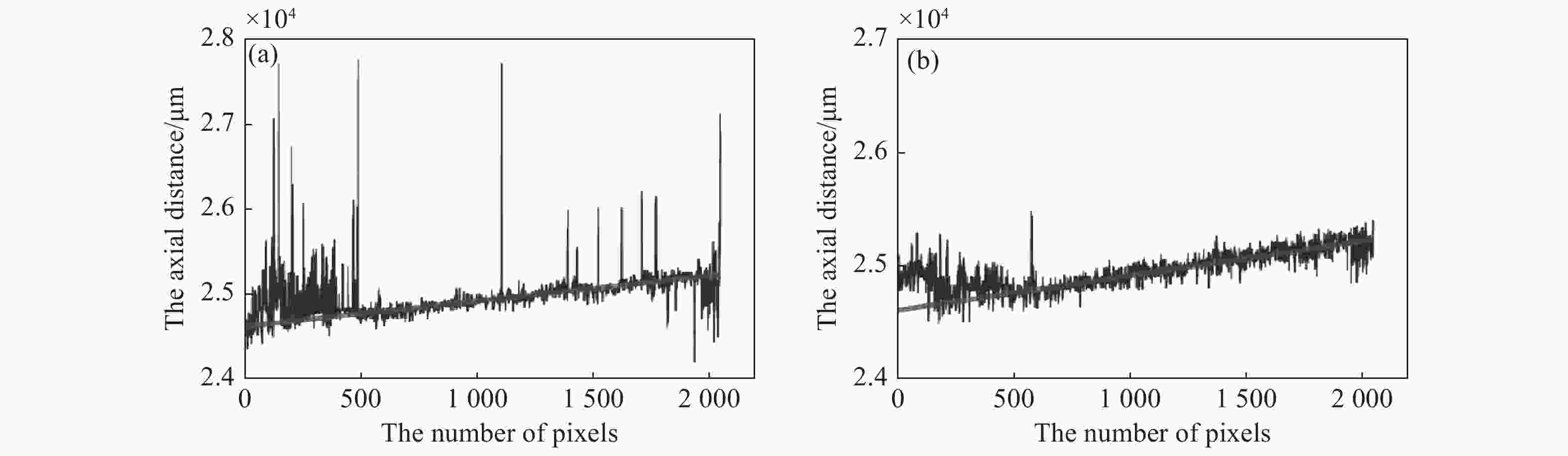

图 10 像素坐标下铅芯三维重建结果。(a)小波变换局部方差算子的三维重建结果;(b)局部灰度方差算子的三维重建结果

Figure 10. Three-dimensional reconstruction results of the lead core in pixel coordinates. (a) Three-dimensional reconstruction results calculated by local variance operator of wavelet transform; (b) three-dimensional reconstruction result calculated by local gray-level variance operator

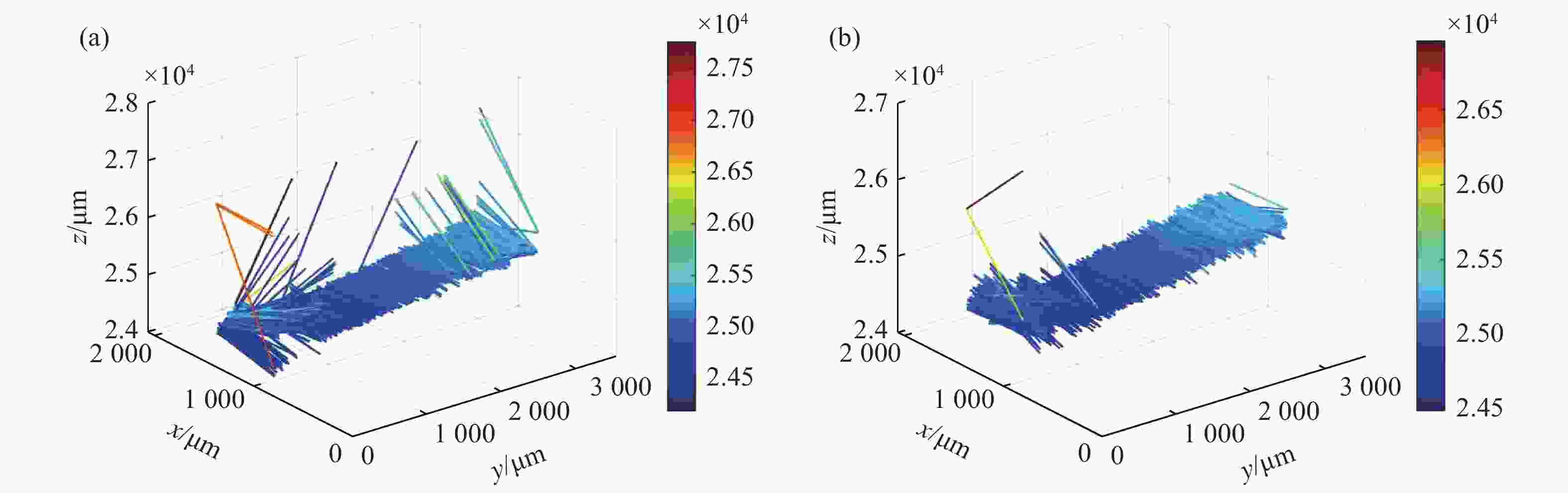

图 11 距离坐标下铅芯三维重建结果。(a)小波变换局部方差算子的三维重建结果;(b)局部灰度方差算子的三维重建结果

Figure 11. Three-dimensional reconstruction results of the lead core in the distance coordinates. (a) Three-dimensional reconstruction result calculated by local variance operator of the wavelet transform; (b) three-dimensional reconstruction results calculated by local gray-level variance operator

-

[1] SHI G F, ZHANG Y SH, ZHANG H, et al. Analysis of the influence of installation tilt error on the tool setting accuracy by laser diffraction[J]. Applied Optics, 2018, 57(12): 3012-3020. doi: 10.1364/AO.57.003012 [2] ZHENG K B, HE N, LI L, et al. Method of precise tool setting for micro turning[J]. Materials Science Forum, 2012, 723: 383-388. doi: 10.4028/www.scientific.net/MSF.723.383 [3] XU M, NAKAMOTO K, TAKEUCHI Y. Compensation method for tool setting errors based on non-contact on-machine measurement[J]. International Journal of Automation Technology, 2020, 14(1): 66-72. doi: 10.20965/ijat.2020.p0066 [4] 曾超, 高洪跃, 刘吉成, 等. 动态全息三维显示研究最新进展[J]. 物理学报,2015,64(12):124215. doi: 10.7498/aps.64.124215ZENG CH, GAO H Y, LIU J CH, et al. Latest developments of dynamic holographic three-dimensional display[J]. Acta Physica Sinica, 2015, 64(12): 124215. (in Chinese) doi: 10.7498/aps.64.124215 [5] 陈竹, 姜宏振, 刘旭, 等. 数字全息术用于光学元件表面缺陷形貌测量[J]. 光学 精密工程,2017,25(3):576-583. doi: 10.3788/OPE.20172503.0576CHEN ZH, JIANG H ZH, LIU X, et al. Measurement of surface defects of optical elements using digital holography[J]. Optics and Precision Engineering, 2017, 25(3): 576-583. (in Chinese) doi: 10.3788/OPE.20172503.0576 [6] KOZACKI T, CHLIPALA M, MAKOWSKI P L. Color Fourier orthoscopic holography with laser capture and an LED display[J]. Optics Express, 2018, 26(9): 12144-12158. doi: 10.1364/OE.26.012144 [7] 朱越, 刘文耀, 刘方超, 等. 用数字全息术检测轮胎气泡缺陷[J]. 光学 精密工程,2009,17(5):1099-1104.ZHU Y, LIU W Y, LIU F CH, et al. Inspection of air bubble defect in tires by digital holography[J]. Optics and Precision Engineering, 2009, 17(5): 1099-1104. (in Chinese) [8] 王雪, 刘虹遥, 路鑫超, 等. 无透镜全息显微细胞成像[J]. 光学 精密工程,2020,28(8):1644-1650.WANG X, LIU H Y, LU X CH, et al. Cell imaging by holographic lens-free microscopy[J]. Optics and Precision Engineering, 2020, 28(8): 1644-1650. (in Chinese) [9] 郭力菡, 王新柯, 张岩. 生物组织的太赫兹数字全息成像[J]. 光学 精密工程,2017,25(3):611-615. doi: 10.3788/OPE.20172503.0611GUO L H, WANG X K, ZHANG Y. Terahertz digital holographic imaging of biological tissues[J]. Optics and Precision Engineering, 2017, 25(3): 611-615. (in Chinese) doi: 10.3788/OPE.20172503.0611 [10] DI CAPRIO G, FERRARA M A, MICCIO L, et al. Holographic imaging of unlabelled sperm cells for semen analysis: a review[J]. Journal of Biophotonics, 2015, 8(10): 779-789. doi: 10.1002/jbio.201400093 [11] 杨德兴, 许增奇, 姜宏振, 等. 利用数字全息干涉术测量电路板的连续弯曲形变[J]. 光学 精密工程,2012,20(8):1789-1795. doi: 10.3788/OPE.20122008.1789YANG D X, XU Z Q, JIANG H ZH, et al. Measurement of continuous bending deformation for circuit boards by digital holographic interferometry[J]. Optics and Precision Engineering, 2012, 20(8): 1789-1795. (in Chinese) doi: 10.3788/OPE.20122008.1789 [12] LI X Y, TANG CH, ZHU X J, et al. Image/video encryption using single shot digital holography[J]. Optics Communications, 2015, 342: 218-223. doi: 10.1016/j.optcom.2014.12.082 [13] SU Y G, XU W J, LI T L, et al. Optical color image encryption based on fingerprint key and phase-shifting digital holography[J]. Optics and Lasers in Engineering, 2021, 140: 106550. doi: 10.1016/j.optlaseng.2021.106550 [14] 马利红, 王辉, 李勇, 等. 全息模拟再现像的三维重构[J]. 光子学报,2006,35(4):595-598.MA L H, WANG H, LI Y, et al. 3-D rebuilding based on numerical reconstruction of the hologram[J]. Acta Photonica Sinica, 2006, 35(4): 595-598. (in Chinese) [15] 阳静, 吴学成, 吴迎春, 等. 数字显微全息重建图像的景深扩展研究[J]. 物理学报,2015,64(11):114209. doi: 10.7498/aps.64.114209YANG J, WU X CH, WU Y CH, et al. Study on extending the depth of field in reconstructed image for a micro digital hologram[J]. Acta Physica Sinica, 2015, 64(11): 114209. (in Chinese) doi: 10.7498/aps.64.114209 [16] 程亚亚, 于化东, 于占江, 等. 微铣刀同轴全息图像增强方法[J]. 中国光学,2020,13(4):705-712. doi: 10.37188/CO.2019-0217CHENG Y Y, YU H D, YU ZH J, et al. Method of enhancing the quality of in-line holographic images for micro-milling tool[J]. Chinese Optics, 2020, 13(4): 705-712. (in Chinese) doi: 10.37188/CO.2019-0217 -

下载:

下载: