-

摘要:

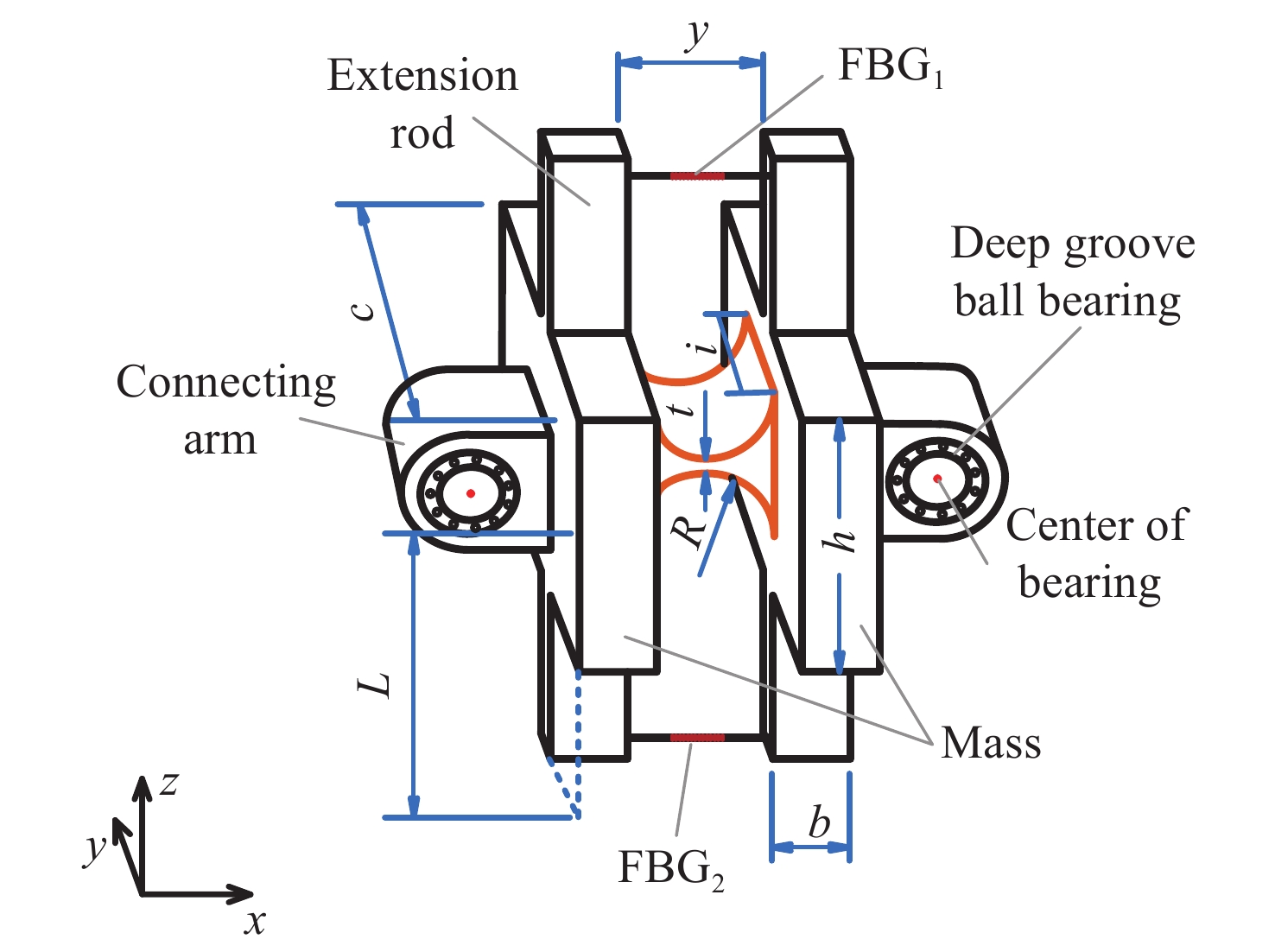

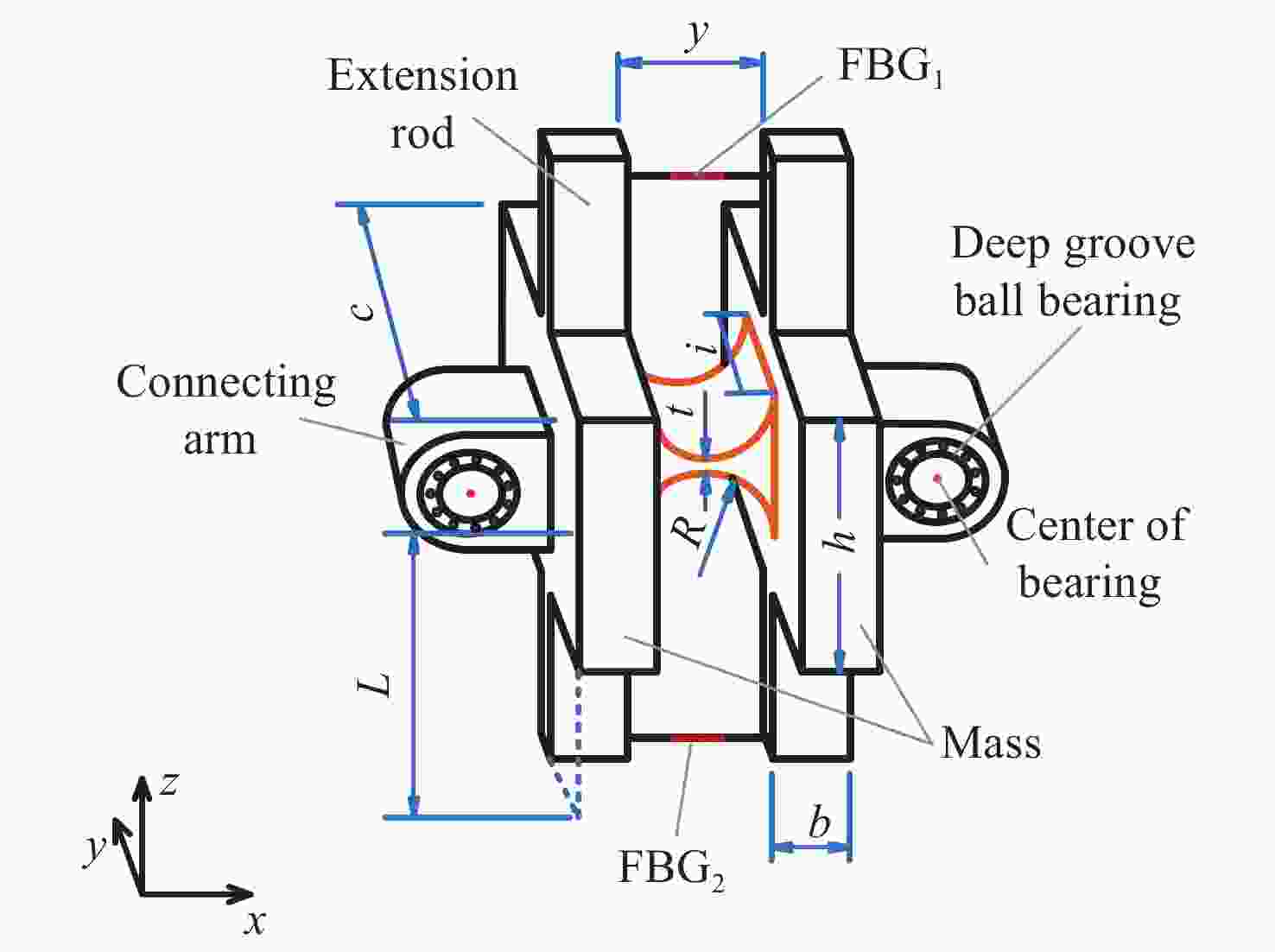

为实现中高频振动信号的测量,本文设计了一种基于轴承和柔性铰链结构的光纤布拉格光栅加速度传感器。首先,基于理论力学模型推导出其固有频率、灵敏度与结构参数的数学模型,然后进行结构优化设计,并制作了传感器实物。在此基础上,对所设计传感器动态特性进行有限元仿真和实验测试。研究结果表明:传感器工作频率为10~1200 Hz,加速度灵敏度达17.25 pm/g,测量误差小于0.3 g,线性度大于0.99,重复性误差为2.33%,且能实现温度补偿。

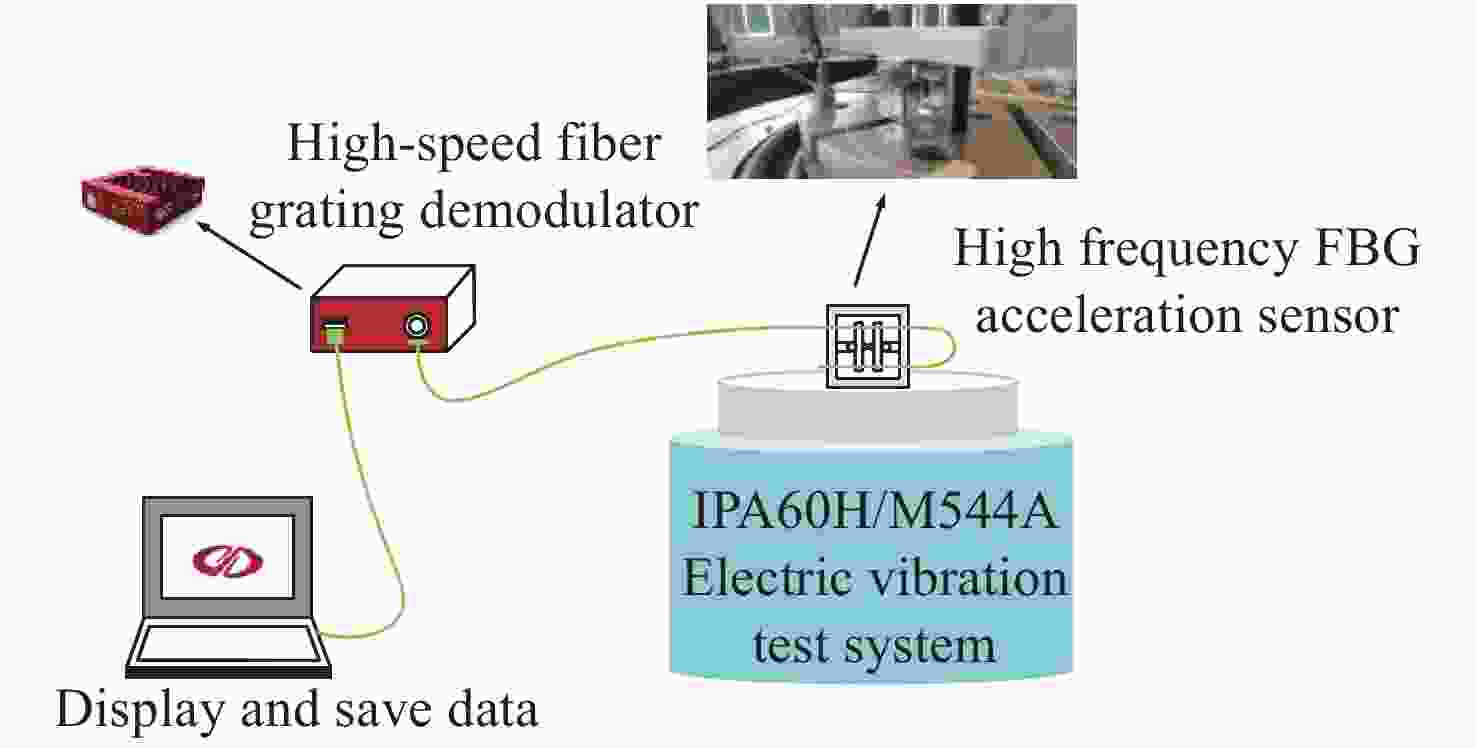

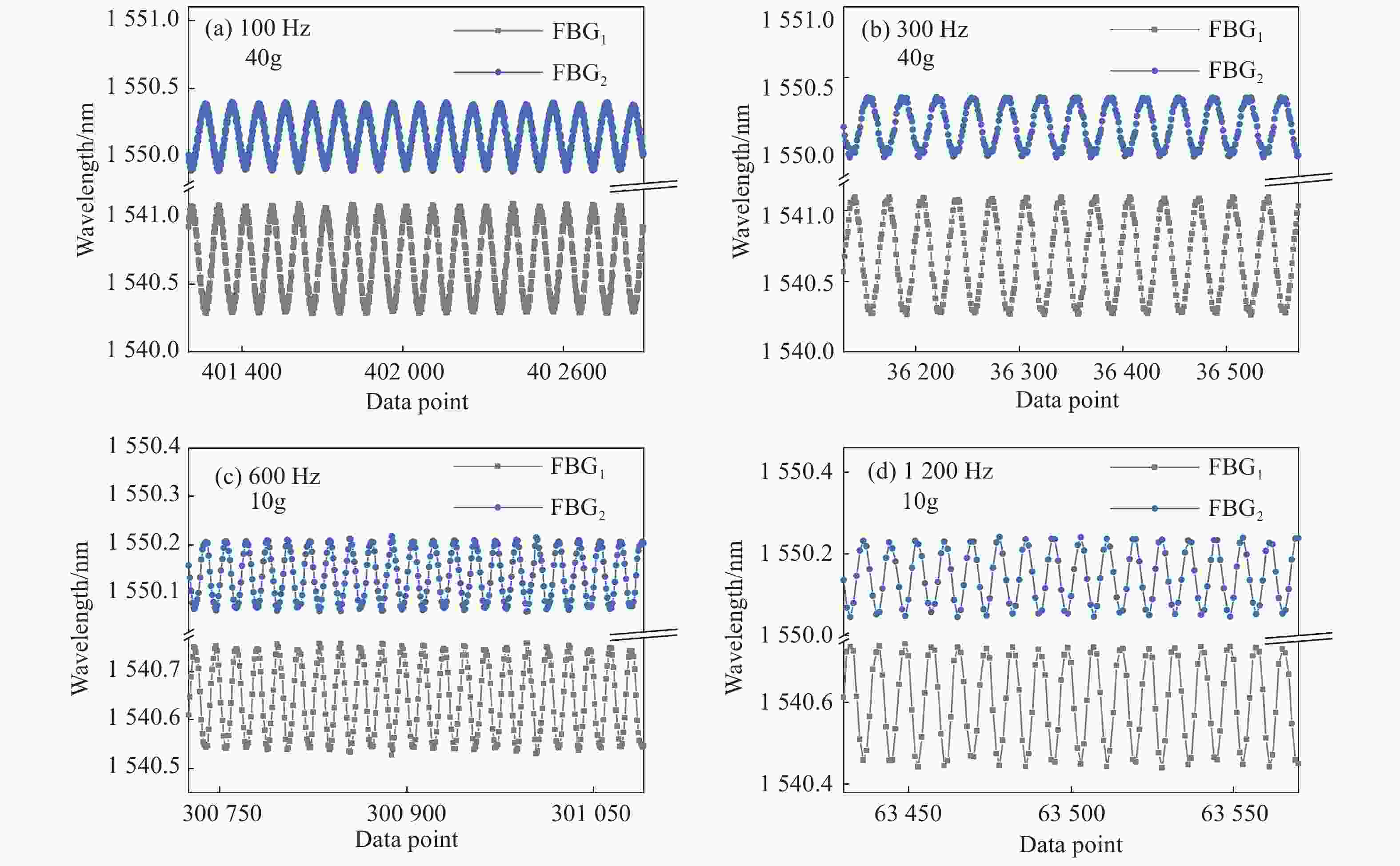

Abstract:We develop a fiber Bragg grating accelerometer based on a bearing and flexure hinge for the measurement of medium-high frequency vibration signals. The mathematical model between its natural frequency and sensitivity and structural parameters is derived based on a mechanical model, and the structural design is optimized based on the theoretical analysis results. With these prerequisites, the sensor was fabricated. Ultimately, its dynamic characteristics are validated using a finite element simulation and vibration experiment. The results show that both its operating frequency range and acceleration sensitivity are 10−1200 Hz and 17.25 pm/g. In addition, this proposed sensor has some advantages such as an error of less than 0.3 g, a good linearity of greater than 0.99, a repeatability error of 2.33%, and it is free of temperature.

-

Key words:

- sensor /

- accelerometer /

- fiber Bragg grating /

- mid-high frequency /

- bearing /

- flexure hinge

-

表 1 加速度传感器尺寸参数

Table 1. Dimensional parameters of FBG accelerometer

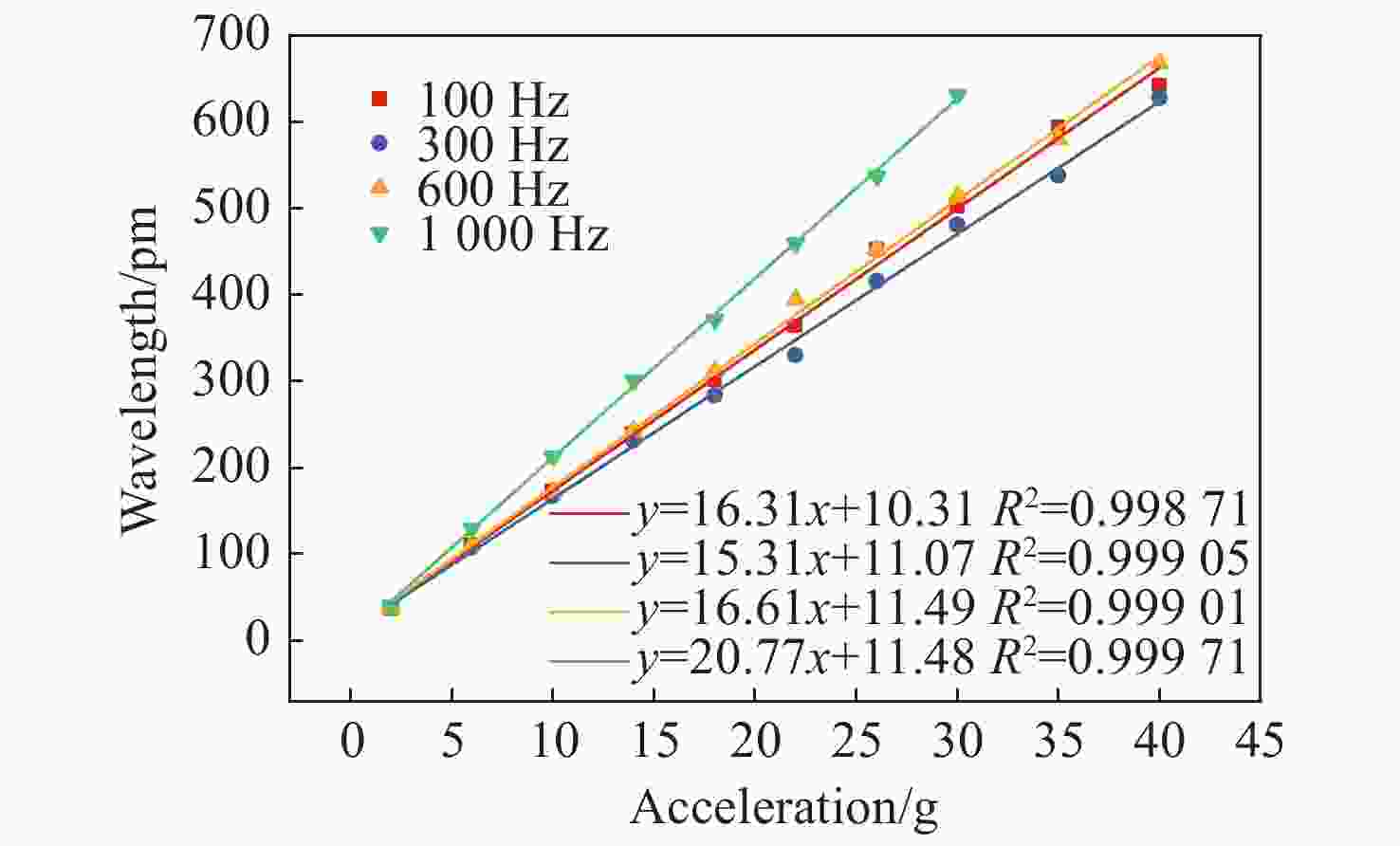

参数 含义 值 Pe 有效弹光系数 0.22 λ1 FBG1中心波长/nm 1540 λ2 FBG2中心波长/nm 1550 R 柔性铰链切割半径/mm 2.5 t 柔性铰链最小厚度/mm 2 i 柔性铰链宽度(y方向长度)/mm 6 b 质量块长/mm 4 c 质量块宽/mm 35 h 质量块高/mm 15 L 质量块质心到延伸杆端部距离/mm 20 E 304不锈钢弹性模量/GPa 210 Af 光纤横截面积/m2 1.23×10−8 Ef 光纤弹性模量/GPa 72 表 2 不同加速度下光栅波长变化量

Table 2. Wavelength shifts of FBG at different accelerations

加速度/g 波长变化量/pm 标准差/pm 第一次 第二次 第三次 平均值 2 42.01 42.37 44.73 43.04 1.48 6 130.60 130.36 134.71 131.89 2.45 10 213.68 217.52 217.53 216.25 2.22 14 301.16 295.53 300.51 299.07 3.08 18 371.33 378.76 385.35 378.48 7.01 22 460.05 457.72 462.66 460.14 2.47 26 538.20 538.20 527.20 534.53 6.35 30 632.40 640.91 626.22 633.18 7.38 表 3 FBG加速度传感器的结构性能对比

Table 3. Performance comparison of FBG accelerometer designed in this paper and reported in other Refs.

-

[1] 顾宏灿, 黄俊斌, 程玲, 等. 20~1250 Hz光纤金宝搏188软件怎么用 加速度传感系统设计[J]. 中国光学(中英文),2017,10(4):469-476. doi: 10.3788/co.20171004.0469GU H C, HUANG J B, CHENG L, et al. 20-1250 Hz fiber laser acceleration sensing system[J]. Chinese Optics, 2017, 10(4): 469-476. (in Chinese) doi: 10.3788/co.20171004.0469 [2] LI J H, MA H, YANG CH Y, et al. Research progress of the laser vibration measurement techniques for acoustic-to-seismic coupling landmine detection[J]. Chinese Optics, 2021, 14(3): 487-502. doi: 10.37188/CO.2020-0134 [3] BAASCH B, HEUSEL J, ROTH M, et al. Train wheel condition monitoring via cepstral analysis of axle box accelerations[J]. Applied Sciences, 2021, 11(4): 1432. doi: 10.3390/app11041432 [4] GOTO H, KANEKO Y, YOUNG J, et al. Extreme accelerations during earthquakes caused by elastic flapping effect[J]. Scientific Reports, 2019, 9(1): 1117. doi: 10.1038/s41598-018-37716-y [5] 朱峰, 唐毓涛, 高晨轩. 弓网离线电弧对CRH380BL型动车组速度传感器的电磁干扰机理及抑制[J]. 中国铁道科学,2016,37(6):69-74. doi: 10.3969/j.issn.1001-4632.2016.06.09ZHU F, TANG Y T, GAO CH X. Mechanism and suppression of electromagnetic interference of pantograph-catenary arc to speed sensor of CRH380BL electric multiple unit[J]. China Railway Science, 2016, 37(6): 69-74. (in Chinese) doi: 10.3969/j.issn.1001-4632.2016.06.09 [6] 吴虎, 孔勇, 王振伟, 等. 基于端点检测与信号重组的光纤分布式传感信号识别[J]. 光子学报,2021,50(11):1106005. doi: 10.3788/gzxb20215011.1106005WU H, KONG Y, WANG ZH W, et al. Fiber distributed sensing signal recognition based on endpoint detection and signal recombination[J]. Acta Photonica Sinica, 2021, 50(11): 1106005. (in Chinese) doi: 10.3788/gzxb20215011.1106005 [7] JIANG SH D, WANG Y Y, ZHANG F X, et al. A high-sensitivity FBG accelerometer and application for flow monitoring in oil wells[J]. Optical Fiber Technology, 2022, 74: 103128. doi: 10.1016/j.yofte.2022.103128 [8] QIU ZH CH, SUN R, TENG Y T, et al. Design and test of a low frequency fiber Bragg grating acceleration sensor with double tilted cantilevers[J]. Optics Communications, 2022, 507: 127663. doi: 10.1016/j.optcom.2021.127663 [9] 魏莉, 刘壮, 李恒春, 等. 基于“士”字形梁增敏结构的光纤光栅振动传感器[J]. 光学学报,2019,39(11):1106004.WEI L, LIU ZH, LI H CH, et al. Fiber Bragg grating vibration sensor based on sensitive structure for "Shi"-shaped beam[J]. Acta Optica Sinica, 2019, 39(11): 1106004. (in Chinese) [10] ZHAO X F, JIA ZH A, FAN W, et al. A fiber Bragg grating acceleration sensor with temperature compensation[J]. Optik, 2021, 241: 166993. doi: 10.1016/j.ijleo.2021.166993 [11] LI T L, TAN Y G, HAN X, et al. Diaphragm based fiber Bragg grating acceleration sensor with temperature compensation[J]. Sensors, 2017, 17(1): 218. [12] 魏莉, 余玲玲, 姜达州, 等. 基于膜片与菱形结构的光纤布拉格光栅加速度传感器[J]. 中国金宝搏188软件怎么用 ,2019,46(9):0910003. doi: 10.3788/CJL201946.0910003WEI L, YU L L, JIANG D ZH, et al. Fiber Bragg grating accelerometer based on diaphragm and diamond structure[J]. Chinese Journal of Lasers, 2019, 46(9): 0910003. (in Chinese) doi: 10.3788/CJL201946.0910003 [13] FAN W, WEN J, GAO H, et al. Low-frequency fiber Bragg grating accelerometer based on diaphragm-type cantilever[J]. Optical Fiber Technology, 2022, 70: 102888. doi: 10.1016/j.yofte.2022.102888 [14] WU H, LIN Q J, ZHAO N, et al. A high-frequency acceleration sensor based on fiber grating[J]. IEEE Transactions on Instrumentation and Measurement, 2021, 70: 7003808. [15] WANG X F, GUO Y X, XIONG L, et al. High-frequency optical fiber Bragg grating accelerometer[J]. IEEE Sensors Journal, 2018, 18(12): 4954-4960. doi: 10.1109/JSEN.2018.2833885 [16] LI Y ZH, MA Q Q, CHEN F Y, et al. A flexible hinge accelerometer based on dual short fiber Bragg grating[J]. Sensors and Actuators A:Physical, 2022, 344: 113695. doi: 10.1016/j.sna.2022.113695 [17] LIANG L, WANG H, LI Z CH, et al. Miniature bending-resistant fiber grating accelerometer based on a flexible hinge structure[J]. Optics Express, 2022, 30(19): 33502-33514. doi: 10.1364/OE.465453 [18] YAN B, LIANG L. A novel fiber Bragg grating accelerometer based on parallel double flexible hinges[J]. IEEE Sensors Journal, 2020, 20(9): 4713-4718. doi: 10.1109/JSEN.2019.2925017 [19] LUO X D, LI Y F, FENG D Q, et al. Fiber Bragg grating accelerometer based on symmetrical double flexure hinges[J]. Optical Fiber Technology, 2022, 68: 102795. doi: 10.1016/j.yofte.2021.102795 [20] QIU ZH CH, ZHANG J Q, TENG Y T, et al. Hinge-type FBG acceleration sensor based on double elastic plate[J]. Scientific Reports, 2021, 11(1): 24319. doi: 10.1038/s41598-021-03628-7 [21] LI Z CH, LIANG L, WANG H, et al. A medium-frequency fiber Bragg grating accelerometer based on flexible hinges[J]. Sensors, 2021, 21(21): 6968. doi: 10.3390/s21216968 [22] FRIEDRICH R, LAMMERING R, HEURICH T. Nonlinear modeling of compliant mechanisms incorporating circular flexure hinges with finite beam elements[J]. Precision Engineering, 2015, 42: 73-79. doi: 10.1016/j.precisioneng.2015.04.001 [23] 吴鹰飞, 周兆英. 柔性铰链转动刚度计算公式的推导[J]. 仪器仪表学报,2004,25(1):125-128,137. doi: 10.3321/j.issn:0254-3087.2004.01.032WU Y F, ZHOU ZH Y. Deduction of design equation of flexure hinge[J]. Chinese Journal of Scientific Instrument, 2004, 25(1): 125-128,137. (in Chinese) doi: 10.3321/j.issn:0254-3087.2004.01.032 [24] 周晓林, 崔长彩, 范伟, 等. 柔性铰链的3种模型计算和分析[J]. 机械设计,2011,28(5):5-9. doi: 10.13841/j.cnki.jxsj.2011.05.014ZHOU X L, CUI CH C, FAN W, et al. Computation and analysis of the three models of flexure hinge[J]. Journal of Machine Design, 2011, 28(5): 5-9. (in Chinese) doi: 10.13841/j.cnki.jxsj.2011.05.014 [25] 谢官模. 振动力学[M]. 北京: 国防工业出版社, 2007.XIE G M. Vibration Mechanical[M]. Beijing: National Defense Industry Press, 2007. (in Chinese) [26] 何道清, 张禾, 石明江. 传感器与传感器技术[M]. 4版. 北京: 科学出版社, 2020.HE D Q, ZHANG H, SHI M J. Sensors and Sensor Technology[M]. 4th ed. Beijing: Science Press, 2020. (in Chinese) -

下载:

下载: