Capillary liquid-core optical fiber temperature sensor based on fluorescence intensity ratio

-

摘要:

针对现有光纤荧光温度传感探头制备复杂的问题,本文提出了一种制备简单、成本低廉且性能优异的基于毛细管液芯的光纤荧光温度传感器。首先将对温度敏感的罗丹明B和对温度不敏感的罗丹明123的混合溶液作为温敏材料封装在不锈钢毛细管中制备成传感探头,利用两者荧光发射峰强度的比值进行温度传感。之后对传感探头中混合溶液的浓度和毛细管的结构参数进行了优化,并对传感器的性能进行了测试,最终将其应用于实际生活温度检测中。实验结果表明:该传感器的温度响应范围为30~70 °C,荧光强度比与温度之间呈二次相关,拟合相关系数高达0.9984,且具有很好的准确性、重复性和稳定性,使用时间可达3个月以上,能很好地应用于对日常生活中温度的检测。该光纤荧光温度传感器在实时监测和远端探测方面具有很大的潜力。

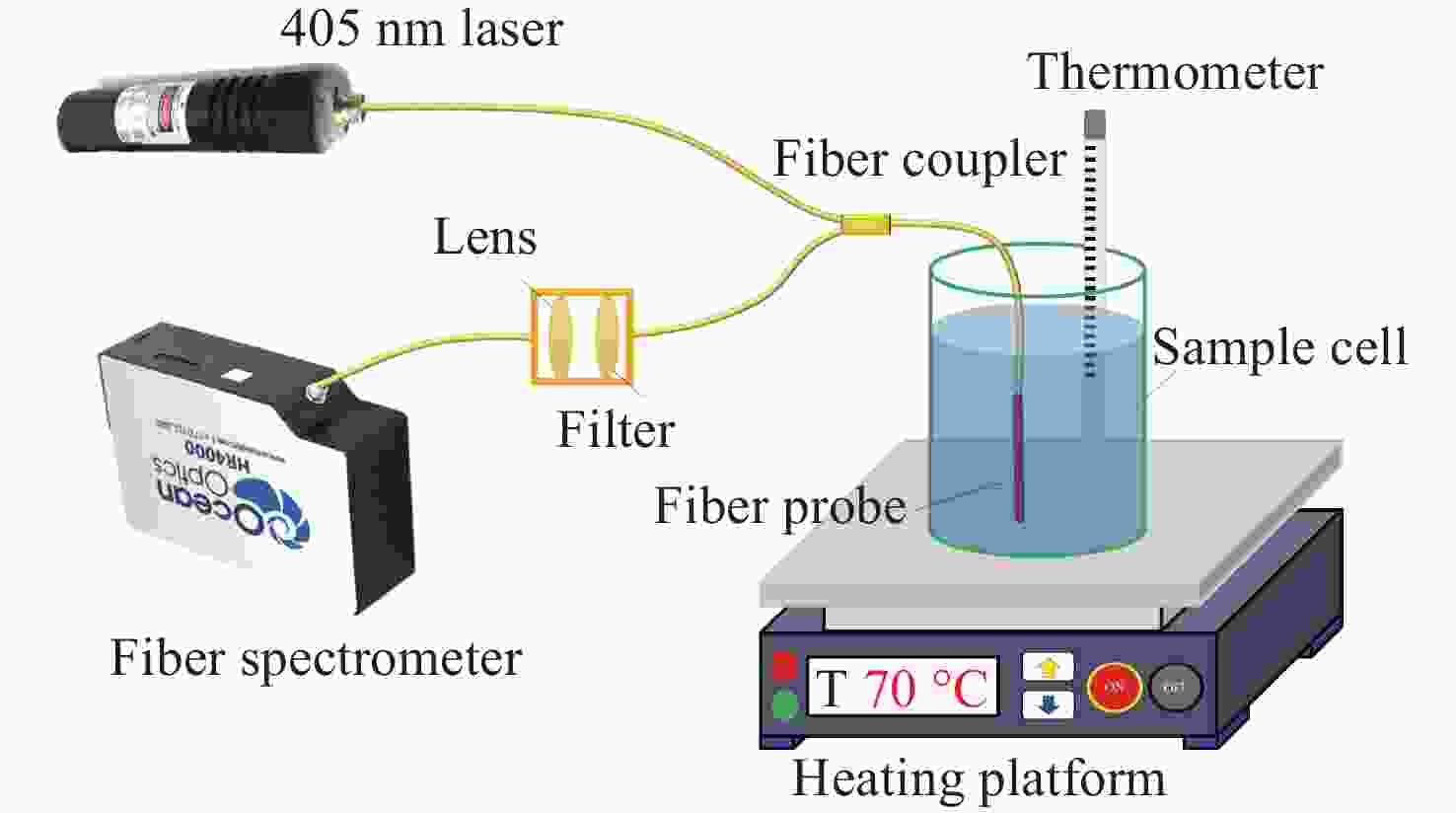

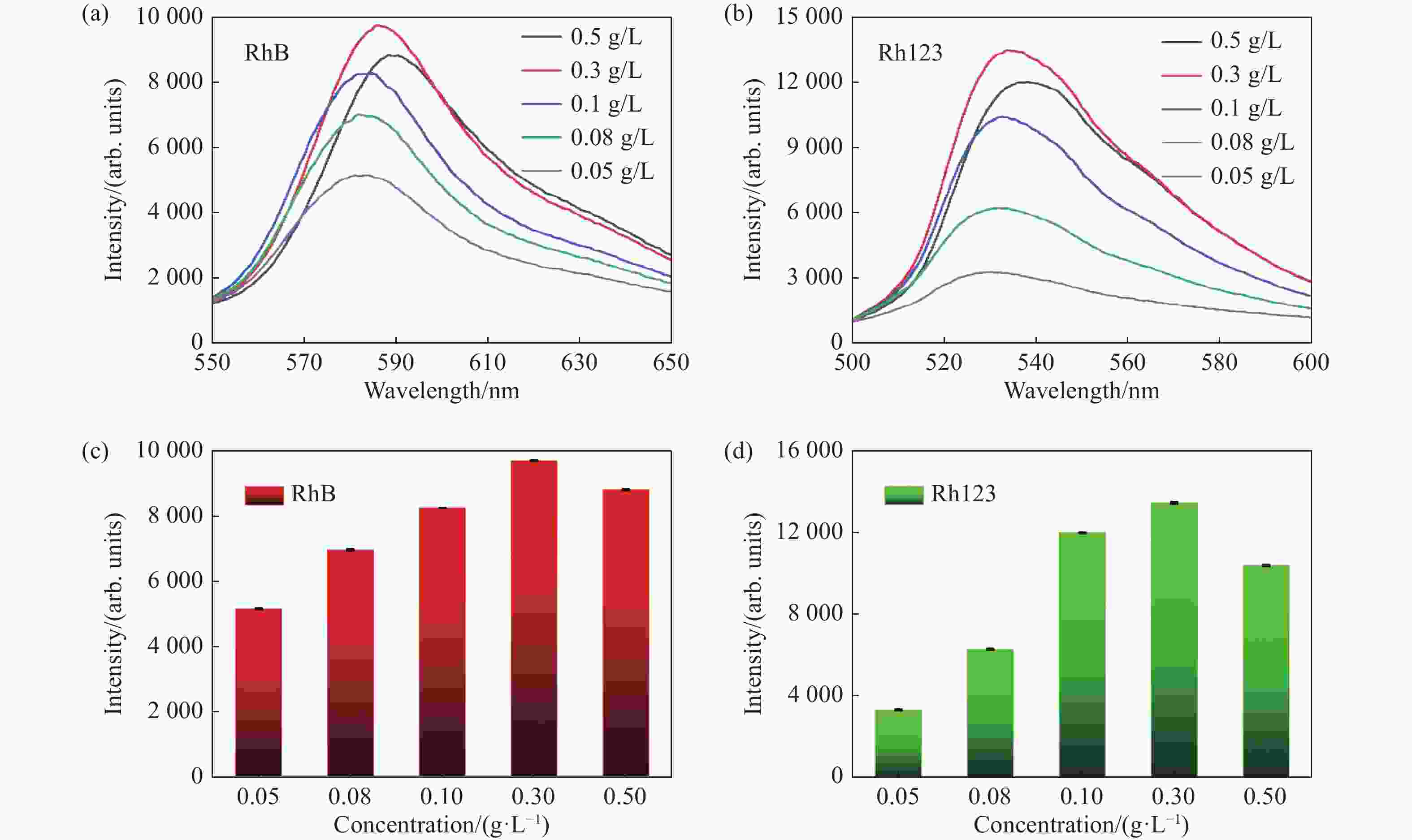

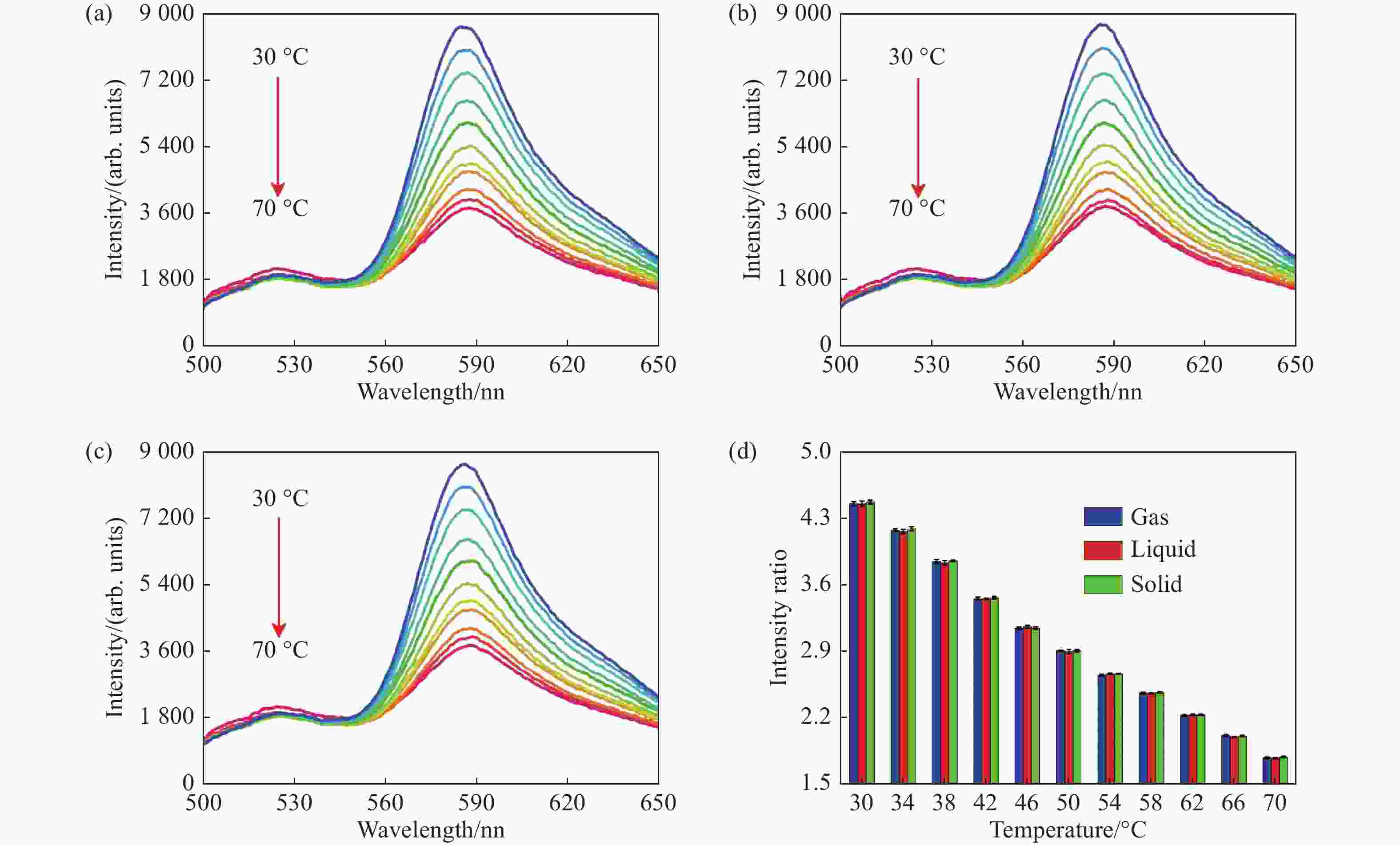

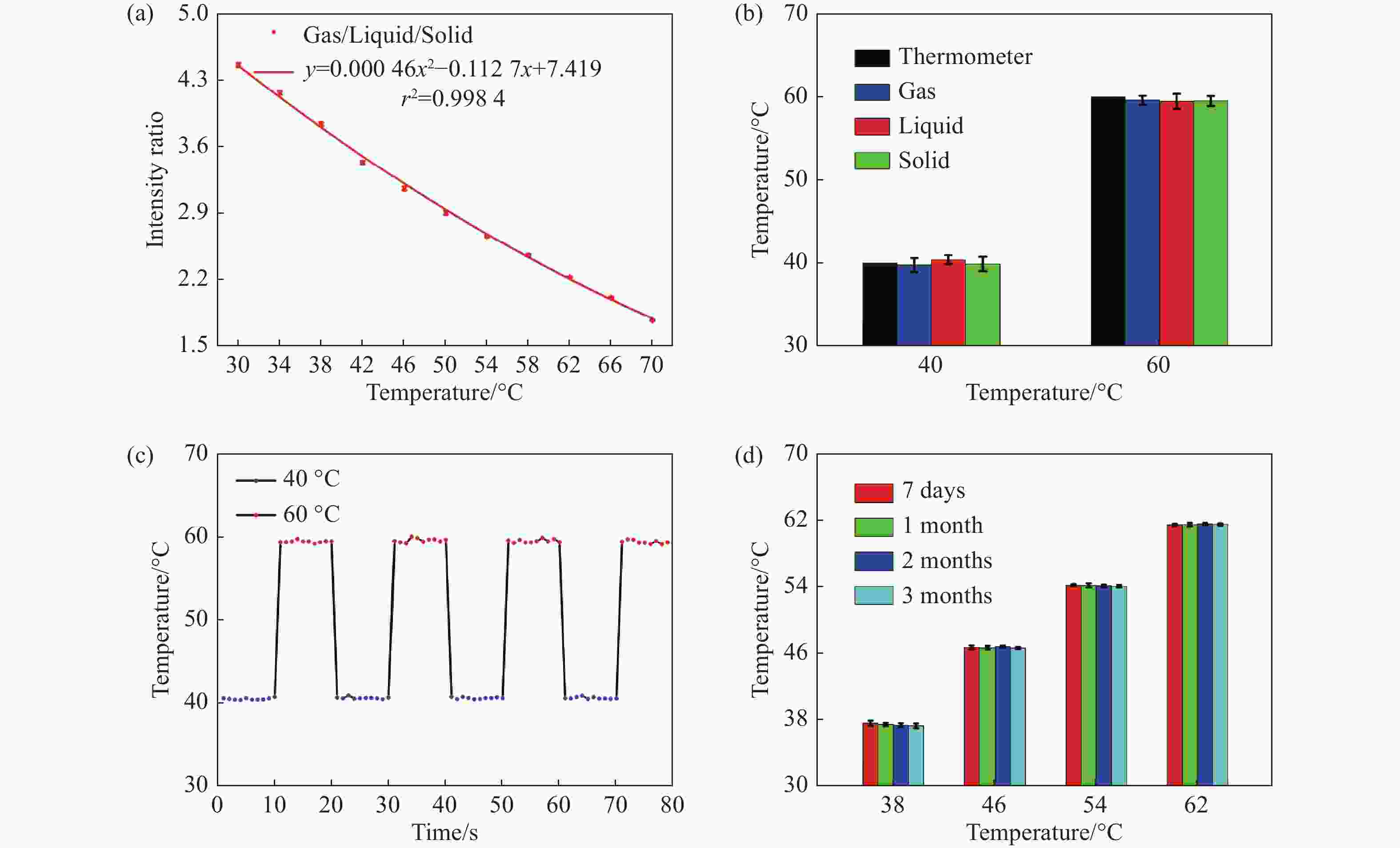

Abstract:Aiming to the problem of the complicated preparation of existing optical fiber fluorescence temperature sensing probes, we propose a simple, cost-effective, and high-performance optical fiber fluorescence temperature sensor based on a capillary liquid core. Firstly, a mixed solution consisting of temperature-sensitive rhodamine B and temperature-insensitive rhodamine 123 was used as the temperature-sensitive material and encapsulated in a stainless-steel capillary to prepare a sensing probe. The ratio of the fluorescence emission peak intensities of the two dyes was utilized for temperature sensing. Subsequently, the sensing probe’s mixed solution concentration and capillary structural parameters were optimized. Then, the performance of the sensor was tested. Finally, the sensor was applied to real-life temperature measurements. The experimental results demonstrate that the sensor has a temperature response range of 30−70 °C and that there is a quadratic correlation between the fluorescence intensity ratio and the temperature, with the fitted correlation coefficient as high as 0.9984. The sensor exhibits excellent accuracy, repeatability, and stability, with more than three months of service time. Moreover, it can be well-utilized to detect temperature in daily life. The optical fiber fluorescence temperature sensor shows significant potential for real-time monitoring and remote detection applications.

-

Key words:

- optical fiber /

- temperature sensor /

- fluorescence intensity ratio /

- rhodamine

-

图 4 传感探头结构参数的优化。(a)温度上升光谱;(b)温度下降光谱;(c)温升温降的信号对比;(d)长度的优化;(e)外径的优化;(f)光纤浸入深度比的优化

Figure 4. Structure parameter optimization of sensing probe. Spectra of temperature (a) raising and (b) dropping; (c) comparison of temperature raising and dropping; optimization of (d) length, (e) outer diameter and (f) fiber insertion ratio

-

[1] SHIMADA K, TAKASHIMA H, WANG R P, et al. Capacitance temperature sensor using ferroelectric (Sr0.95Ca0.05)TiO3 perovskite[J]. Ferroelectrics, 2006, 331(1): 141-145. doi: 10.1080/00150190600737701 [2] 薛光辉, 柴敬轩. 热电偶传感器温控系统误差研究[J]. 中国测试,2019,45(9):100-104. doi: 10.11857/j.issn.1674-5124.2018100039XUE G H, CHAI J X. Temperature control error research based on thermocouple sensor[J]. China Measurement & Testing Technology, 2019, 45(9): 100-104. (in Chinese). doi: 10.11857/j.issn.1674-5124.2018100039 [3] LEE J M, CHO I T, LEE J H, et al. Enhancement of temperature sensitivity for metal-insulator-semiconductor temperature sensors by using Bi2Mg2/3Nb4/3O7 film[J]. Japanese Journal of Applied Physics, 2012, 51(8R): 080206. doi: 10.1143/JJAP.51.080206 [4] BANG J, LEE W S, PARK B, et al. Highly sensitive temperature sensor: ligand-treated Ag nanocrystal thin films on PDMS with thermal expansion strategy[J]. Advanced Functional Materials, 2019, 29(32): 1903047. doi: 10.1002/adfm.201903047 [5] LEE Y T, CHOI W J, CHAE Y C. Resistor-based temperature sensors: a technical review[J]. IDEC Journal of Integrated Circuits and Systems, 2021, 7(1): 24-29. [6] YANG Z R, YUAN W H, YU CH Y. Hollow core Bragg fiber-based sensor for simultaneous measurement of curvature and temperature[J]. Sensors, 2021, 21(23): 7956. doi: 10.3390/s21237956 [7] PENG G L, HE J, YANG SH P, et al. Application of the fiber-optic distributed temperature sensing for monitoring the liquid level of producing oil wells[J]. Measurement, 2014, 58: 130-137. doi: 10.1016/j.measurement.2014.08.012 [8] ROMAN M, ZHU CH, O’MALLEY R J, et al. Distributed fiber-optic sensing with low bending loss based on thin-core fiber[J]. IEEE Sensors Journal, 2021, 21(6): 7672-7680. doi: 10.1109/JSEN.2021.3050702 [9] MILIOU A. In-fiber interferometric-based sensors: overview and recent advances[J]. Photonics, 2021, 8(7): 265. doi: 10.3390/photonics8070265 [10] ZHANG Y, LIU ZH, LI Y, et al. Electrospun fibers embedded with microcrystal for optical temperature sensing[J]. Journal of Alloys and Compounds, 2021, 855: 157410. doi: 10.1016/j.jallcom.2020.157410 [11] YANG K, XU R, MENG Q Y, et al. Er3+/Yb3+ co-doped TeO2–ZnO–ZnF2–La2O3 glass with a high fluorescence intensity ratio for an all-fiber temperature sensor[J]. Journal of Luminescence, 2020, 222: 117145. doi: 10.1016/j.jlumin.2020.117145 [12] KHLAIFI H, ZRELLI A, EZZEDINE T. Optical fiber sensors in border detection application: temperature, strain and pressure distinguished detection using fiber Bragg grating and fluorescence intensity ratio[J]. Optik, 2021, 229: 166257. doi: 10.1016/j.ijleo.2021.166257 [13] 李爱武, 单天奇, 国旗, 等. 光纤法布里-珀罗干涉仪高温传感器研究进展[J]. 中国光学(中英文),2022,15(4):609-624. doi: 10.37188/CO.2021-0219LI A W, SHAN T Q, GUO Q, et al. Research progress of optical fiber Fabry-Perot interferometer high temperature sensors[J]. Chinese Optics, 2022, 15(4): 609-624. (in Chinese). doi: 10.37188/CO.2021-0219 [14] ZHANG H, YE J T, WANG X L, et al. Highly reliable all-fiber temperature sensor based on the fluorescence intensity ratio (FIR) technique in Er3+/Yb3+ co-doped NaYF4 phosphors[J]. Journal of Materials Chemistry C, 2019, 7(48): 15269-15275. doi: 10.1039/C9TC05011F [15] REN X T, GAO J, SHI H N, et al. A flexible and portable all-fiber temperature sensor based on the upconversion luminescence of octahedral NaBi(WO4)2: Er3+/Yb3+ phosphors[J]. Dalton Transactions, 2021, 50(3): 917-925. doi: 10.1039/D0DT03762A [16] ZHANG M, LI A ZH, YU J B, et al. In-fiber temperature sensor based on green up-conversion luminescence in an Er3+-Yb3+ co-doped tellurite glass microsphere[J]. Optics Letters, 2019, 44(13): 3214-3217. doi: 10.1364/OL.44.003214 [17] MAI Y F, LI B Y, ZHOU G Y, et al. Research on temperature sensor using rhodamine6G film coated microstructure optical fiber[J]. IEEE Sensors Journal, 2020, 20(1): 202-207. doi: 10.1109/JSEN.2019.2938766 [18] LI H, ZHANG Y D, SHAO L, et al. Luminescence probe for temperature sensor based on fluorescence intensity ratio[J]. Optical Materials Express, 2017, 7(3): 1077-1083. doi: 10.1364/OME.7.001077 [19] JIANG X F, LIN CH, HUANG Y Q, et al. Hybrid fiber optic sensor, based on the Fabry-Perot interference, assisted with fluorescent material for the simultaneous measurement of temperature and pressure[J]. Sensors (Basel), 2019, 19(5): 1097. doi: 10.3390/s19051097 [20] ZHAO F, KIM J. The Effect of temperature on photoluminescence enhancement of quantum dots in brain slices[J]. Journal of Nanoscience and Nanotechnology, 2017, 17(4): 2606-2609. doi: 10.1166/jnn.2017.13332 [21] SUN S S, ZHANG J H, Wang ZH, et al. Anomalous thermally-activated NIR emission of ESIPT modulated Nd-complexes for optical fiber sensing devices[J]. Chemical Communications, 2018, 54(49): 6304-6307. doi: 10.1039/C8CC02345J [22] 王玉田, 胡俏丽, 石军彦. 基于荧光机理的光纤温度测量仪[J]. 光学学报,2010,30(3):655-659. doi: 10.3788/AOS20103003.0655WANG Y T, HU Q L, SHI J Y. Optical fiber thermometer based on fluorescence mechanism[J]. Acta Optica Sinica, 2010, 30(3): 655-659. (in Chinese). doi: 10.3788/AOS20103003.0655 [23] ZHAO Y T, PANG CH L, WEN ZH, et al. A microfiber temperature sensor based on fluorescence lifetime[J]. Optics Communications, 2018, 426: 231-236. doi: 10.1016/j.optcom.2018.05.025 [24] WU J, YIN X J, WANG W Y, et al. All-fiber reflecting temperature probe based on the simplified hollow-core photonic crystal fiber filled with aqueous quantum dot solution[J]. Applied Optics, 2016, 55(5): 974-978. doi: 10.1364/AO.55.000974 [25] ZHAO Y, TONG R J, CHEN M Q, et al. Fluorescence temperature sensor based on GQDs solution encapsulated in hollow core fiber[J]. IEEE Photonics Technology Letters, 2017, 29(18): 1544-1547. doi: 10.1109/LPT.2017.2723624 [26] 曹汇敏, 李发光, 戴乐荣, 等. 同步监测氧气和温度的新型便携式传感器[J]. 光学学报,2019,39(6):0628004. doi: 10.3788/AOS201939.0628004CAO H M, LI F G, DAI L R, et al. Novel portable sensor for simultaneous monitoring of oxygen and temperature[J]. Acta Optica Sinica, 2019, 39(6): 0628004. (in Chinese). doi: 10.3788/AOS201939.0628004 [27] KUMAR R, BINETTI L, NGUYEN T H, et al. Optical fibre thermometry using ratiometric green emission of an upconverting nanoparticle-polydimethylsiloxane composite[J]. Sensors and Actuators A:Physical, 2020, 312: 112083. doi: 10.1016/j.sna.2020.112083 [28] 李淑雅, 魏超, 赵晗, 等. 检测汞离子的比色-荧光双通道探针的设计合成及应用[J]. 分析化学,2023,51(2):204-210.LI SH Y, WEI CH, ZHAO H, et al. Synthesis and application of colorimetric and fluorescent dual mode probe for detection of mercury ion[J]. Chinese Journal of Analytical Chemistry, 2023, 51(2): 204-210. (in Chinese). [29] 侯淑华, 李仕琦, 汤立军. 新型水溶性罗丹明类荧光探针的合成及其对游离3价金属离子的识别[J]. 应用化学,2022,39(2):241-246.HOU SH H, LI SH Q, TANG L J. Synthesis of a novel water-soluble rhodamine-based fluorescent probe and its selective detection of free trivalent ions[J]. Chinese Journal of Applied Chemistry, 2022, 39(2): 241-246. (in Chinese). [30] 陈阳, 赵杰, 张嘉惠, 等. 罗丹明B-锆基金属有机框架复合材料高选择性荧光检测铁离子[J]. 分析化学,2021,49(4):642-651.CHEN Y, ZHAO J, ZHANG J H, et al. Integration of rhodamine b into zirconium-based metal-organic framework for selective detection of ferric ion[J]. Chinese Journal of Analytical Chemistry, 2021, 49(4): 642-651. (in Chinese). [31] PANCHUK-VOLOSHINA N, HAUGLAND R P, BISHOP-STEWART J, et al. Alexa dyes, a series of new fluorescent dyes that yield exceptionally bright, photostable conjugates[J]. Journal of Histochemistry & Cytochemistry, 1999, 47(9): 1179-1788. [32] ZHANG T T, WANG ZH J, XIANG H J, et al. Biocompatible superparamagnetic europium-doped iron oxide nanoparticle clusters as multifunctional nanoprobes for multimodal in vivo imaging[J]. ACS Applied Materials & Interfaces, 2021, 13(29): 33850-33861. [33] BARRANCO A, GROENING P. Fluorescent plasma nanocomposite thin films containing nonaggregated rhodamine 6G laser dye molecules[J]. Langmuir, 2006, 22(16): 6719-6722. doi: 10.1021/la053304d -

下载:

下载: