-

摘要:

研究了一种基于微机电系统(MEMS)技术用于高压测量的硅-玻光纤法布里-珀罗(FP)压力传感器。该传感器以硅材料作为敏感元件,将电感耦合等离子体(ICP)干法刻蚀后的单晶硅膜片和高硼硅玻璃阳极键合构成FP腔。传感头使用MEMS技术批量制造,结构稳定、抗过载能力强、在高压环境下不容易失效。实验结果表明,该传感器能够实现30 MPa的高压压力测量,灵敏度为46.94 nm/MPa,线性拟合度为0.99897,测量结果具有较好的一致性和可靠性,所设计的压力传感器在高压检测方面有很强的应用前景。

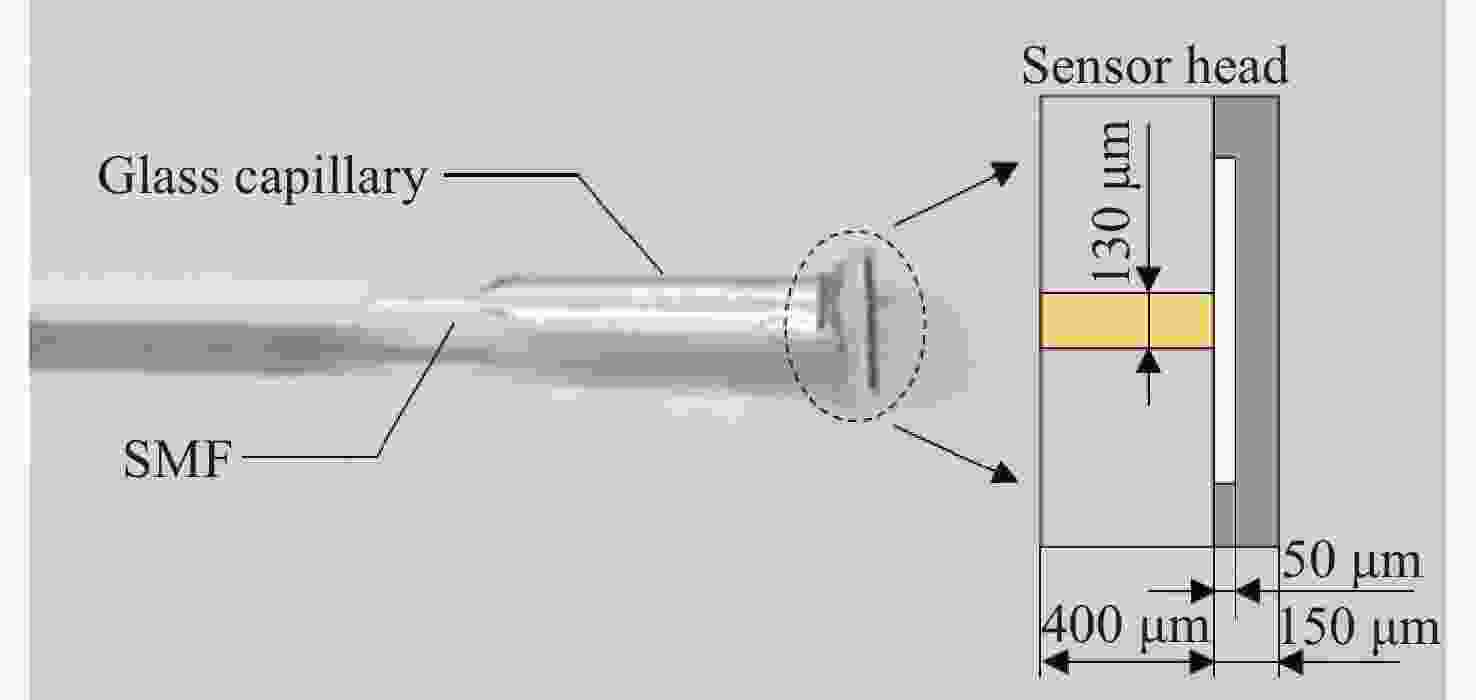

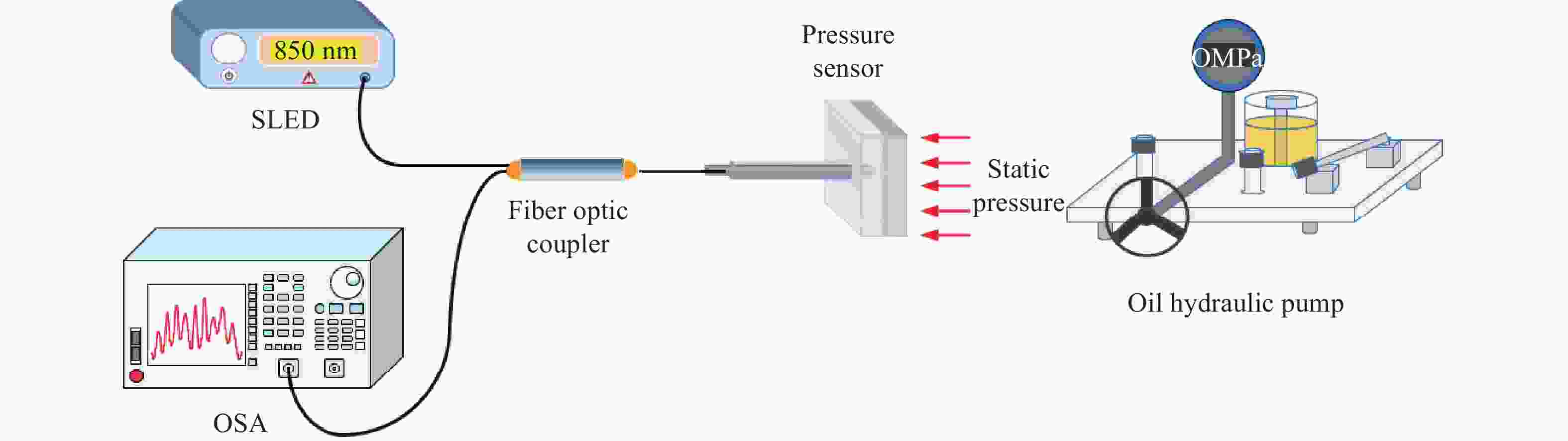

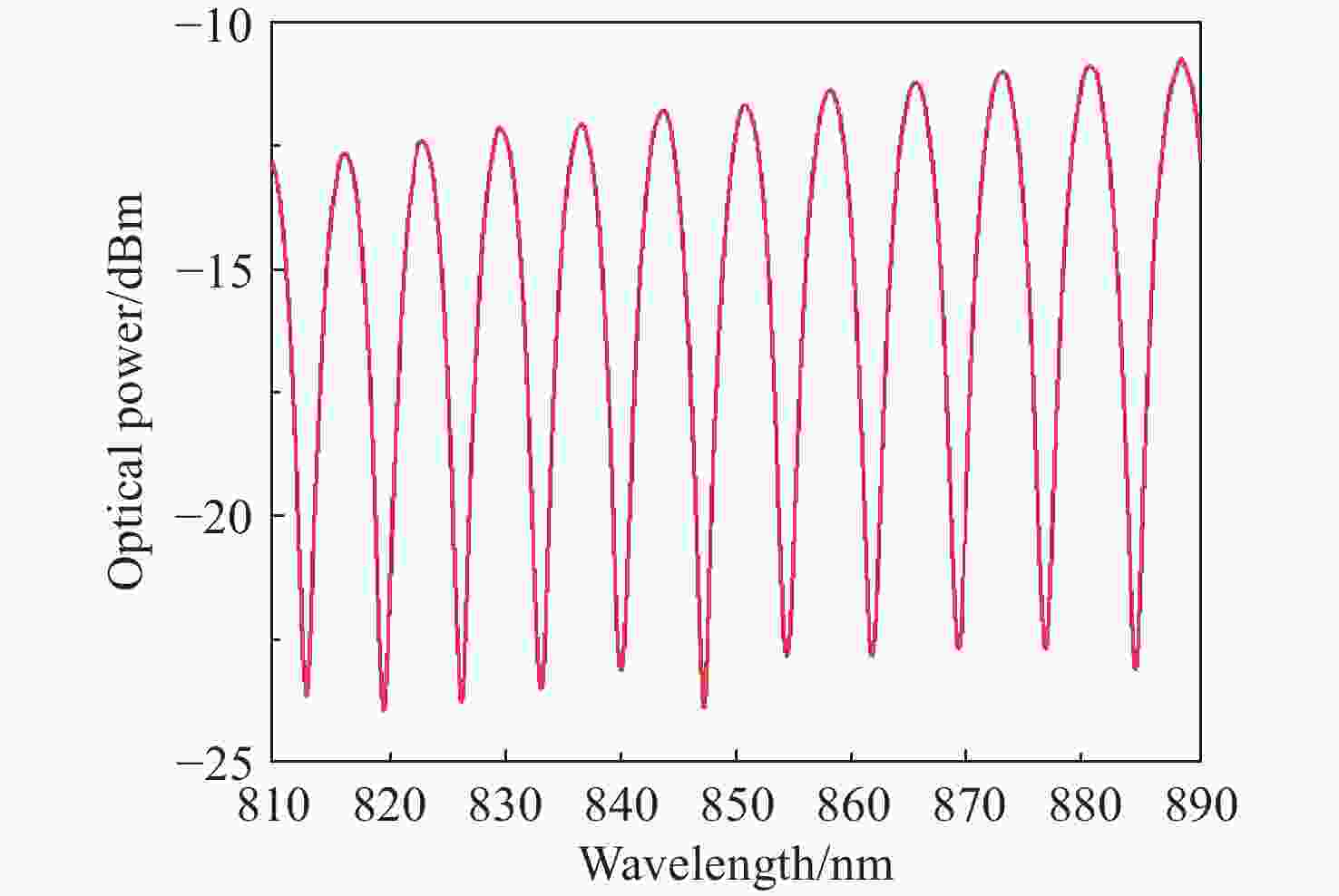

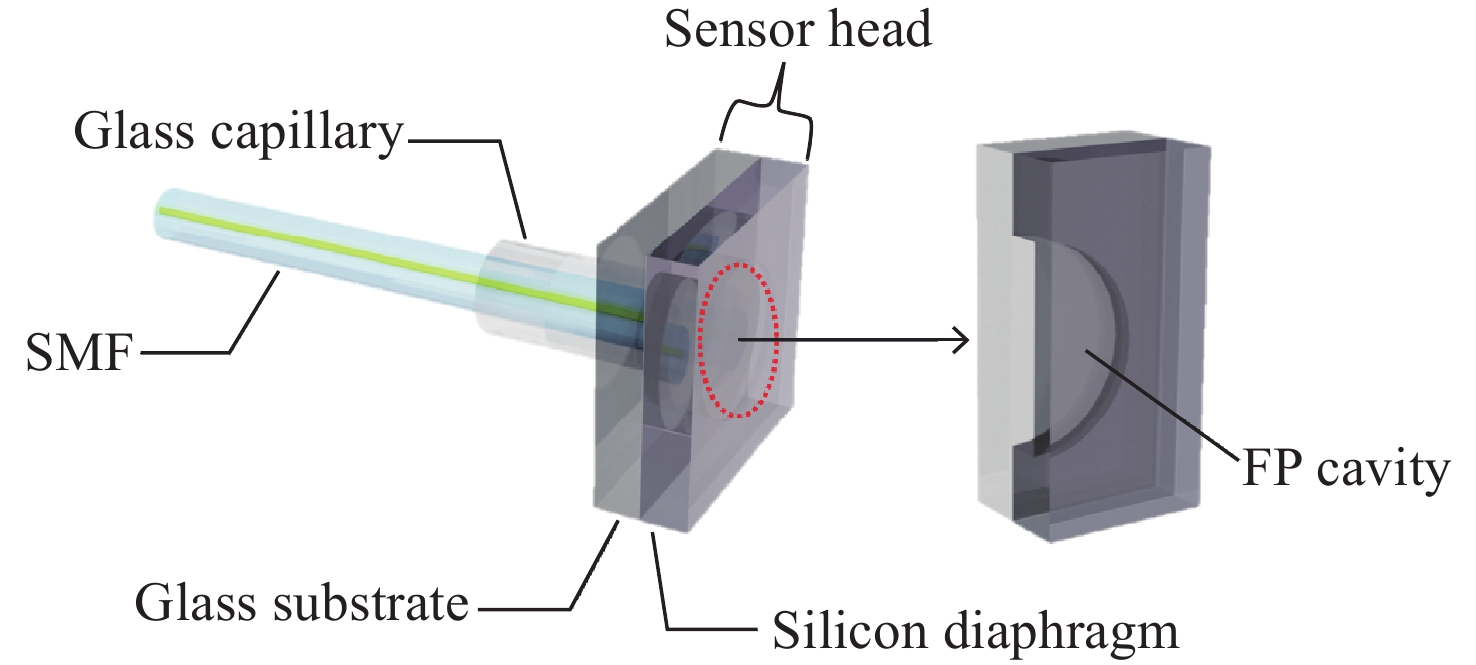

Abstract:We investigate a silicon-glass fiber-optic Fabry-Perot (FP) pressure sensor based on Micro-Electro-Mechanical Systems (MEMS) technology for high-pressure measurements. Silicon material was used as the sensitive element, and the Inductively Coupled Plasma (ICP) dry-etched monocrystalline silicon diaphragm was anode bonded with a high borosilicate glass to form the FP cavity. The sensor head was manufactured in batches utilizing MEMS technology, which is structurally stable, strongly resistant to overload, and not prone to fail in high-pressure environments. The experimental results show that the sensor can acheive high-pressure measurements up to 30 MPa with a sensitivity of 46.94 nm/MPa and a linearity of 0.99897, with high consistency and reliable measurement results. The designed pressure sensor has strong application prospects in high-pressure sensing.

-

Key words:

- MEMS /

- fiber-optic sensor /

- pressure measurement /

- FP interferometer

-

表 1 传感器的参数

Table 1. Sensor parameters

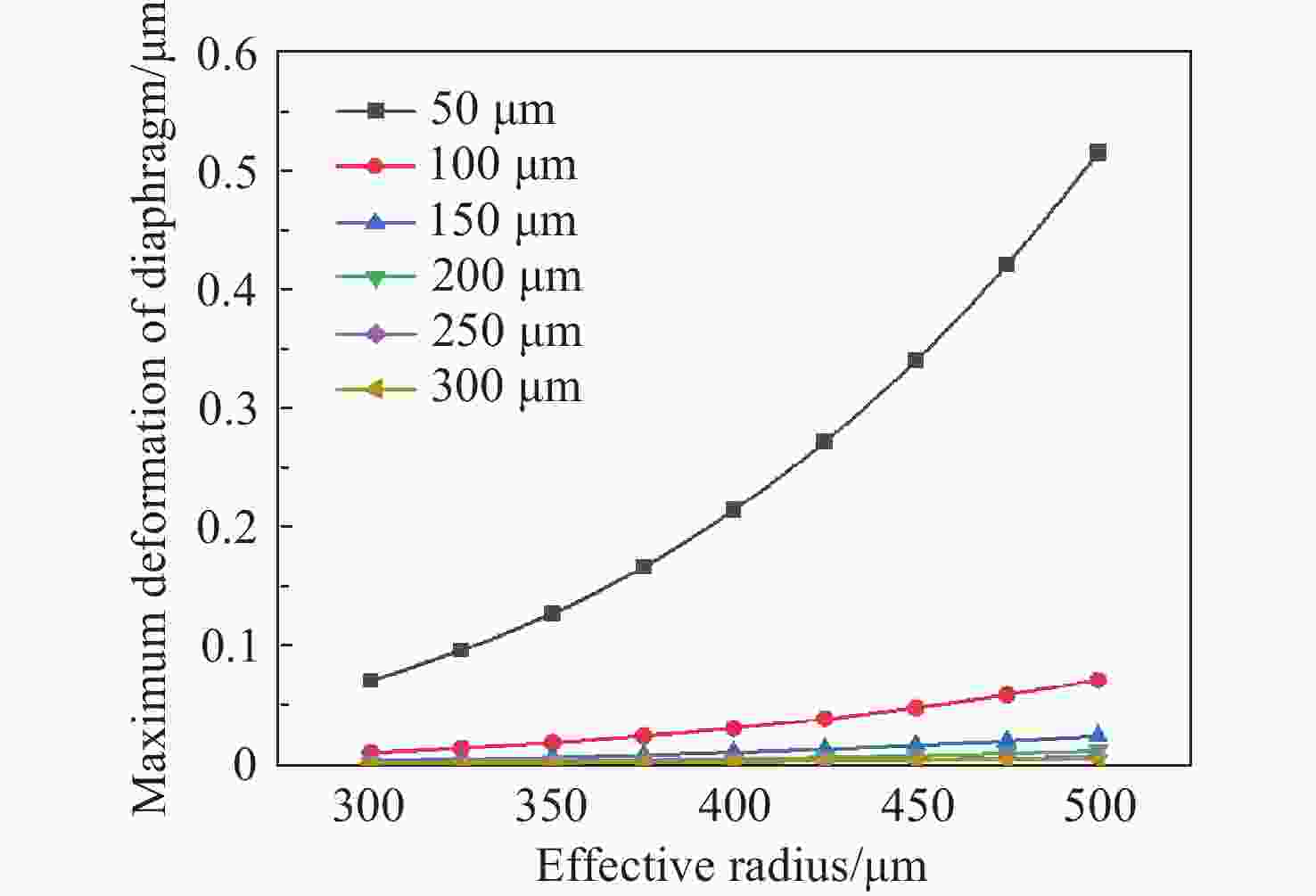

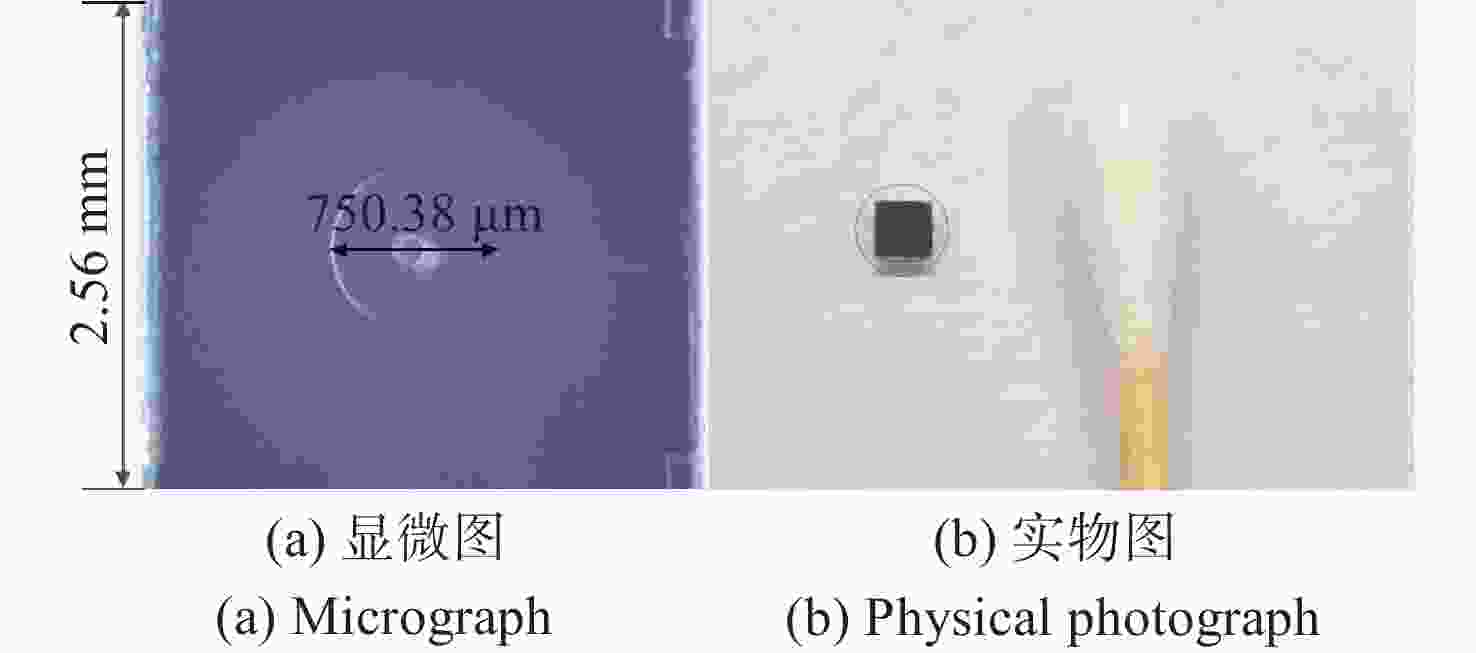

Sensor Parameter Value Silicon diaphragm Effective radius 0.375 mm Thickness 0.1 mm Glass substrate Thickness 0.4 mm Sensor head Side length 2.5 mm -

[1] QI X G, WANG SH, JIANG J F, et al. Fiber optic Fabry-Perot pressure sensor with embedded MEMS micro-cavity for ultra-high pressure detection[J]. Journal of Lightwave Technology, 2019, 37(11): 2719-2725. doi: 10.1109/JLT.2018.2876717 [2] 吴妮珊, 夏历. 基于微波光子学的准分布式光纤传感解调技术[J]. 中国光学,2021,14(2):245-263. doi: 10.37188/CO.2020-0121WU N SH, XIA L. Interrogation technology for quasi-distributed optical fiber sensing systems based on microwave photonics[J]. Chinese Optics, 2021, 14(2): 245-263. (in Chinese). doi: 10.37188/CO.2020-0121 [3] CUI Y, JIANG Y, LIU T M, et al. A dual-cavity Fabry–Perot interferometric fiber-optic sensor for the simultaneous measurement of high-temperature and high-gas-pressure[J]. IEEE Access, 2020, 8: 80582-80587. doi: 10.1109/ACCESS.2020.2991551 [4] 李爱武, 单天奇, 国旗, 等. 光纤法布里-珀罗干涉仪高温传感器研究进展[J]. 中国光学(中英文),2022,15(4):609-624. doi: 10.37188/CO.2021-0219LI A W, SHAN T Q, GUO Q, et al. Research progress of optical fiber Fabry-Perot interferometer high temperature sensors[J]. Chinese Optics, 2022, 15(4): 609-624. (in Chinese). doi: 10.37188/CO.2021-0219 [5] 薛兆康, 国旗, 刘善仁, 等. 油气井下光纤光栅温度压力传感器[J]. 中国光学,2021,14(5):1224-1230. doi: 10.37188/CO.2021-0008XUE ZH K, GUO Q, LIU SH R, et al. Fiber Bragg grating temperature and pressure sensor for oil and gas well[J]. Chinese Optics, 2021, 14(5): 1224-1230. (in Chinese). doi: 10.37188/CO.2021-0008 [6] WANG Q, ZHANG L, SUN CH S, et al. Multiplexed fiber-optic pressure and temperature sensor system for down-hole measurement[J]. IEEE Sensors Journal, 2008, 8(11): 1879-1883. doi: 10.1109/JSEN.2008.2006253 [7] MA J, JU J, JIN L, et al. A compact fiber-tip micro-cavity sensor for high-pressure measurement[J]. IEEE Photonics Technology Letters, 2011, 23(21): 1561-1563. doi: 10.1109/LPT.2011.2164060 [8] WU CH, FU H Y, QURESHI K K, et al. High-pressure and high-temperature characteristics of a Fabry–Perot interferometer based on photonic crystal fiber[J]. Optics Letters, 2011, 36(3): 412-414. doi: 10.1364/OL.36.000412 [9] LIU ZH Y, TSE M L V, WU CH, et al. Intermodal coupling of supermodes in a twin-core photonic crystal fiber and its application as a pressure sensor[J]. Optics Express, 2012, 20(19): 21749-21757. doi: 10.1364/OE.20.021749 [10] LI J SH, JIA P G, FANG G CH, et al. Batch-producible all-silica fiber-optic Fabry–Perot pressure sensor for high-temperature applications up to 800 °C[J]. Sensors and Actuators A: Physical, 2022, 334: 113363. doi: 10.1016/j.sna.2022.113363 [11] BRACE E, GHADERIAN S, GHANNOUM A, et al. Impact of support material deformation in MEMS bulk micromachined diaphragm pressure sensors[J]. Journal of Micromechanics and Microengineering, 2021, 31(5): 055001. doi: 10.1088/1361-6439/abedcb [12] 张亮亮, 胡腾江, 李村, 等. 适用于极端环境的MEMS传感器研究进展[J]. 无人系统技术,2021,4(5):15-22.ZHANG L L, HU T J, LI C, et al. Research progress of MEMS sensors applied in extreme environment[J]. Unmanned Systems Technology, 2021, 4(5): 15-22. (in Chinese). [13] YIN J D, LIU T G, JIANG J F, et al. Batch-producible fiber-optic Fabry–Perot sensor for simultaneous pressure and temperature sensing[J]. IEEE Photonics Technology Letters, 2014, 26(20): 2070-2073. doi: 10.1109/LPT.2014.2347055 [14] GE Y X, CAI K J, WANG T T, et al. MEMS pressure sensor based on optical Fabry–Perot interference[J]. Optik, 2018, 165: 35-40. doi: 10.1016/j.ijleo.2018.03.112 [15] 张韬杰, 江毅, 马维一. 一种高精细度MEMS光纤F-P压力传感器[J]. 金宝搏188软件怎么用 与光电子学进展,2019,56(17):170625.ZHANG T J, JIANG Y, MA W Y. A high fineness optical fiber F-P pressure sensor based on MEMS[J]. Laser & Optoelectronics Progress, 2019, 56(17): 170625. (in Chinese). [16] 梁晓波, 黄漫国, 刘德峰, 等. 全SiC结构高温压力传感器制备及测试[J]. 测控技术,2022,41(6):15-18,25.LIANG X B, HUANG M G, LIU D F, et al. Preparation and testing of high temperature pressure sensor with full SiC structure[J]. Measurement & Control Technology, 2022, 41(6): 15-18,25. (in Chinese). [17] 李加顺, 贾平岗, 王军, 等. 基于石英MEMS技术的光纤法布里-珀罗高温压力传感器[J]. 光子学报,2022,51(6):0606005. doi: 10.3788/gzxb20225106.0606005LI J SH, JIA P G, WANG J, et al. Silica-MEMS-based fiber-optic Fabry-Perot pressure sensor for high-temperature applications[J]. Acta Photonica Sinica, 2022, 51(6): 0606005. (in Chinese). doi: 10.3788/gzxb20225106.0606005 [18] 胡振朋, 贾平岗, 钱江, 等. 蓝宝石高温光纤压力传感器的设计与仿真[J]. 传感技术学报,2021,34(1):1-7.HU ZH P, JIA P G, QIAN J, et al. Design and simulation of sapphire high temperature optical fiber pressure sensor[J]. Chinese Journal of Sensors and Actuators, 2021, 34(1): 1-7. (in Chinese). [19] 郁道银, 谈恒英. 工程光学[M]. 2版. 北京: 机械工业出版社, 2006.YU D Y, TAN H Y. Engineering Optics[M]. 2nd ed. Beijing: China Machine Press, 2006. (in Chinese). [20] 张璐, 柯少颖, 汪建元, 等. 硅基Ⅳ族材料外延生长及其发光和探测器件研究进展[J]. 中国科学: 物理学 力学 天文学,2021,51(3):030005.ZHANG L, KE SH Y, WANG J Y, et al. Research progress in the epitaxial growth of silicon-based group IV materials, and their light emitters and photodetectors[J]. Scientia Sinica Physica, Mechanica & Astronomica, 2021, 51(3): 030005. (in Chinese). [21] CHEN H B, LIU J, ZHANG X X, et al. High-order harmonic-frequency cross-correlation algorithm for absolute cavity length interrogation of white-light fiber-optic Fabry-Perot sensors[J]. Journal of Lightwave Technology, 2020, 38(4): 953-960. doi: 10.1109/JLT.2019.2948214 -

下载:

下载: