-

摘要:

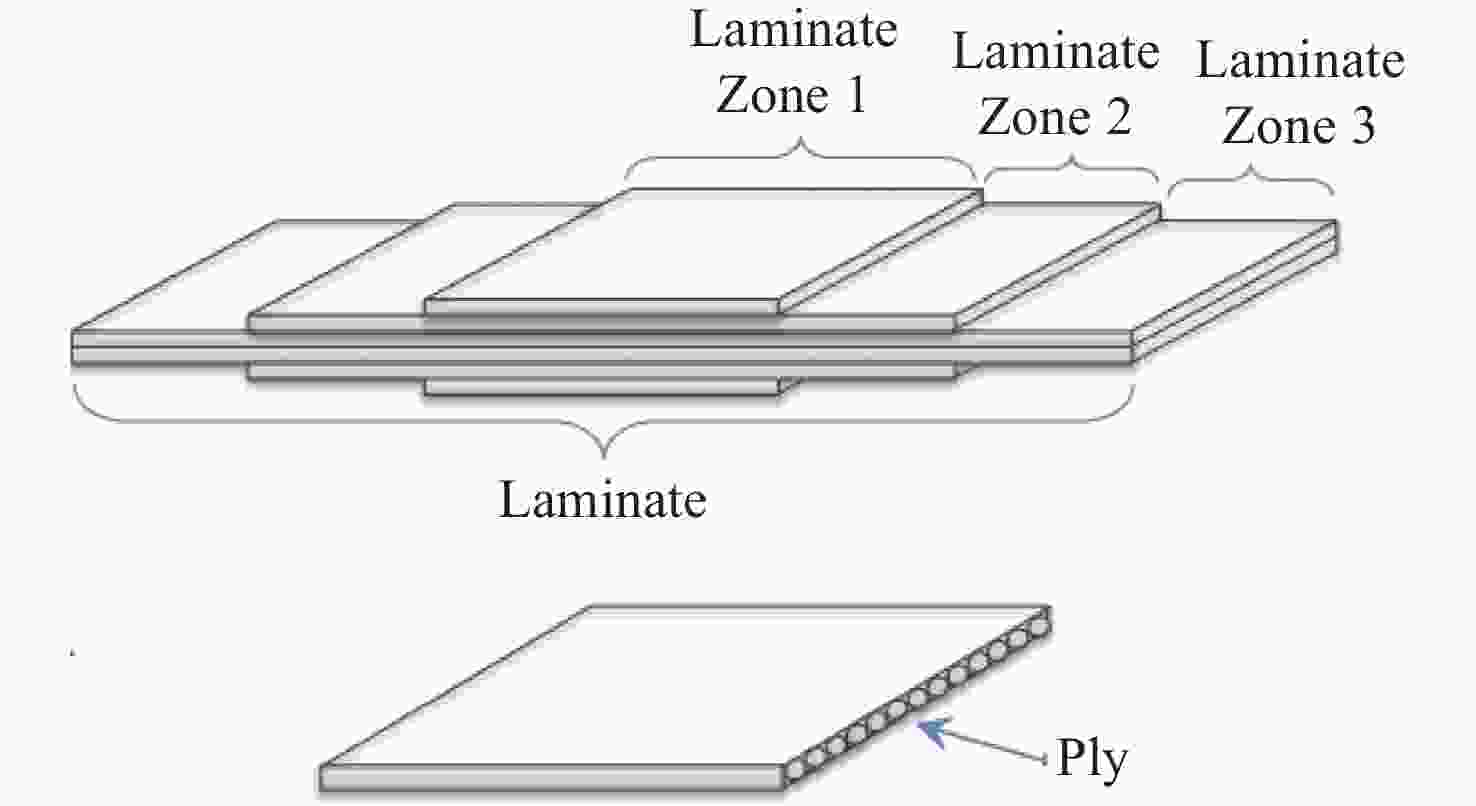

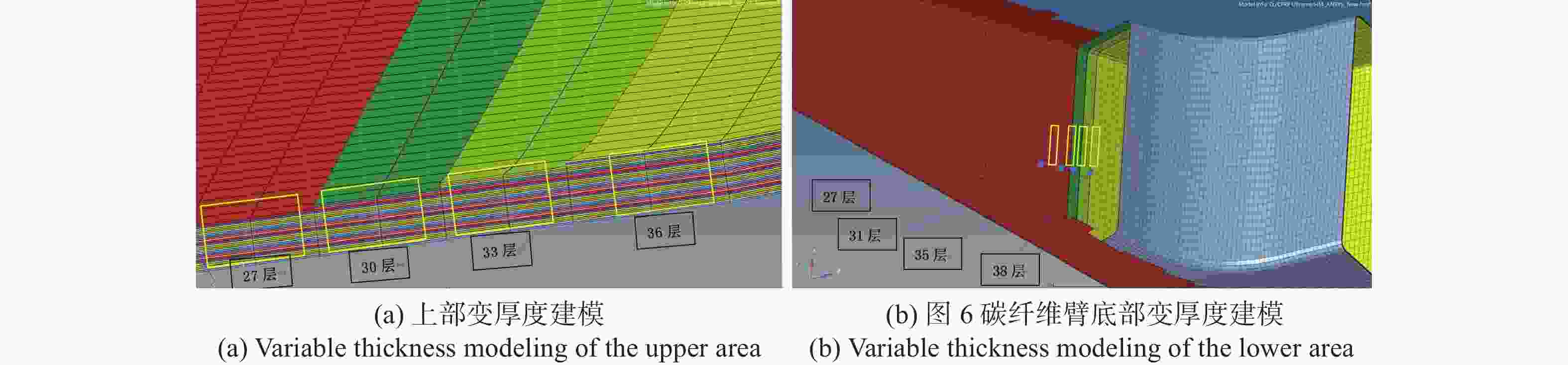

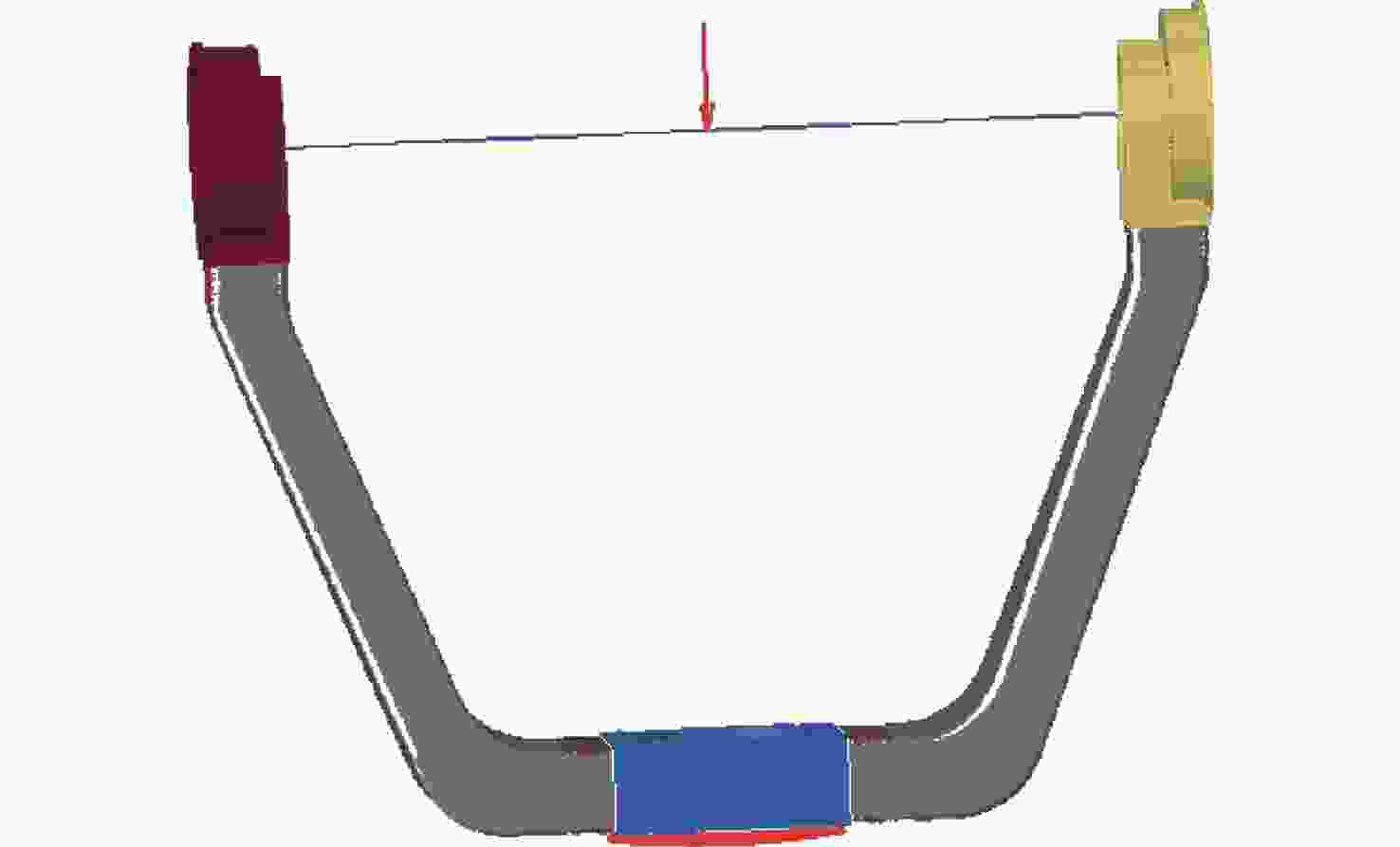

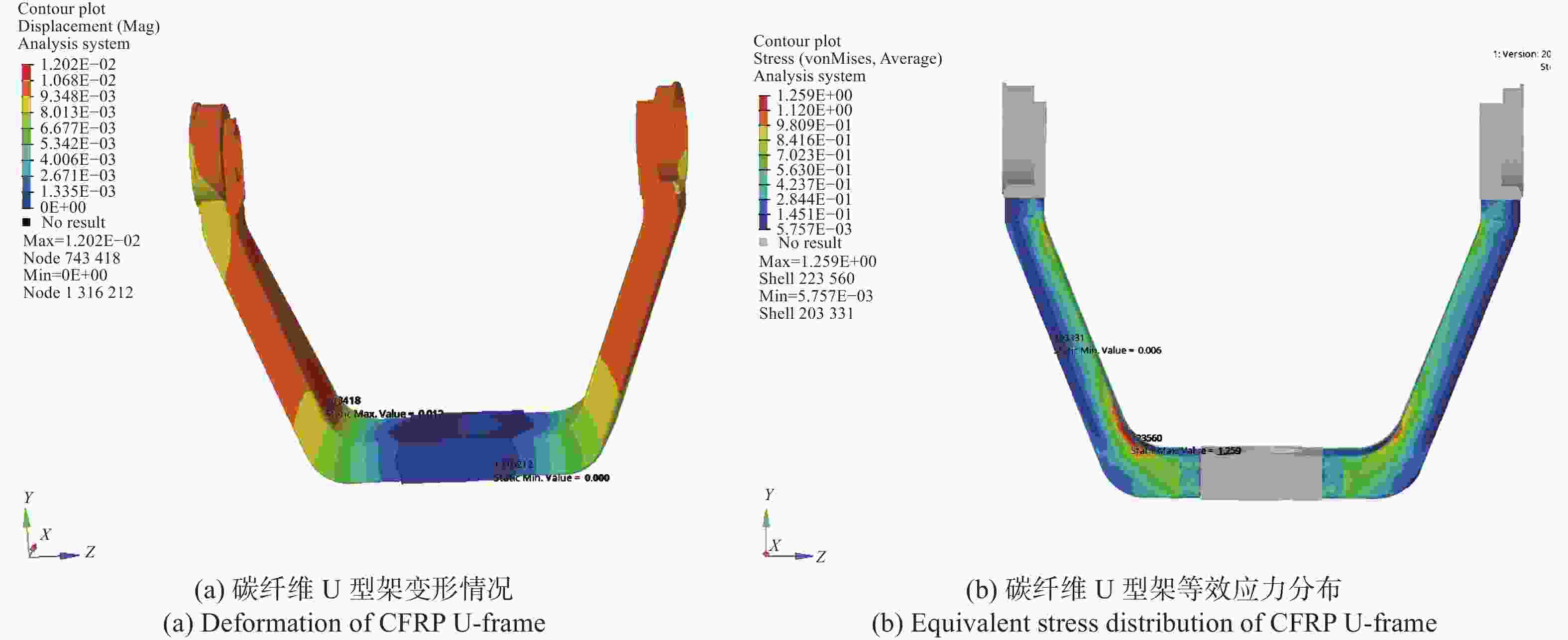

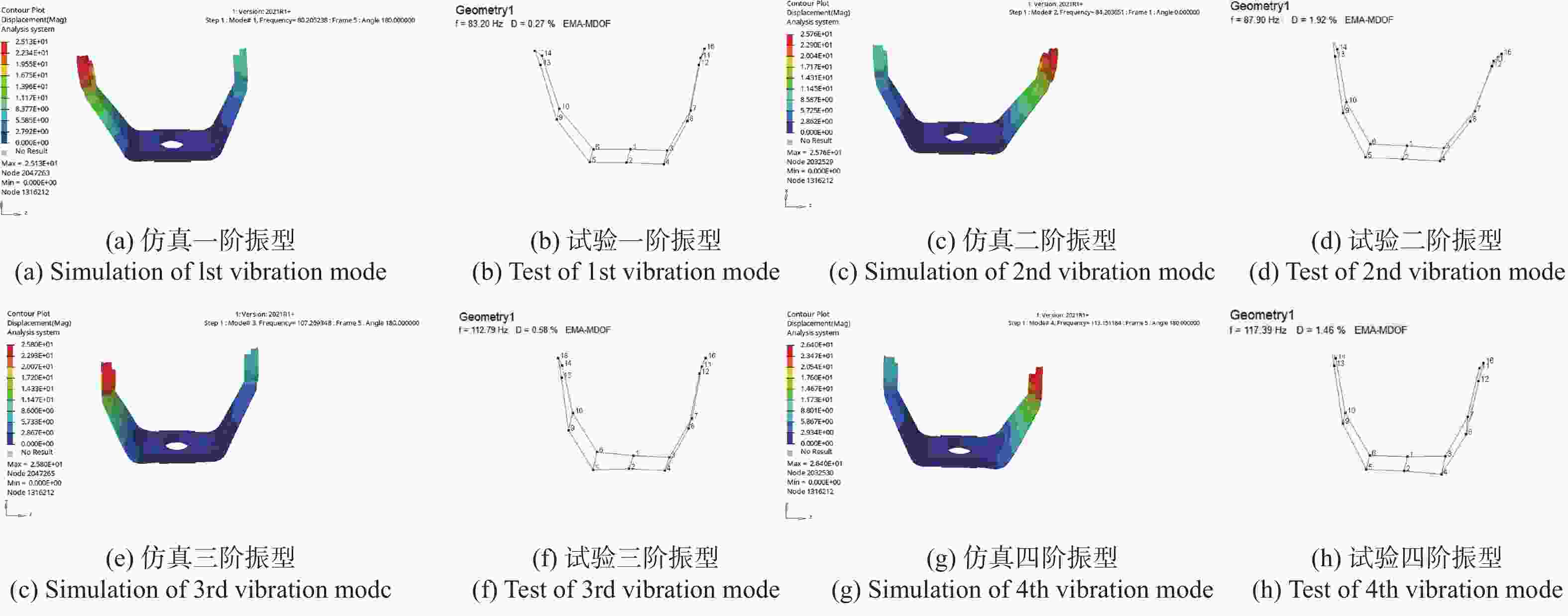

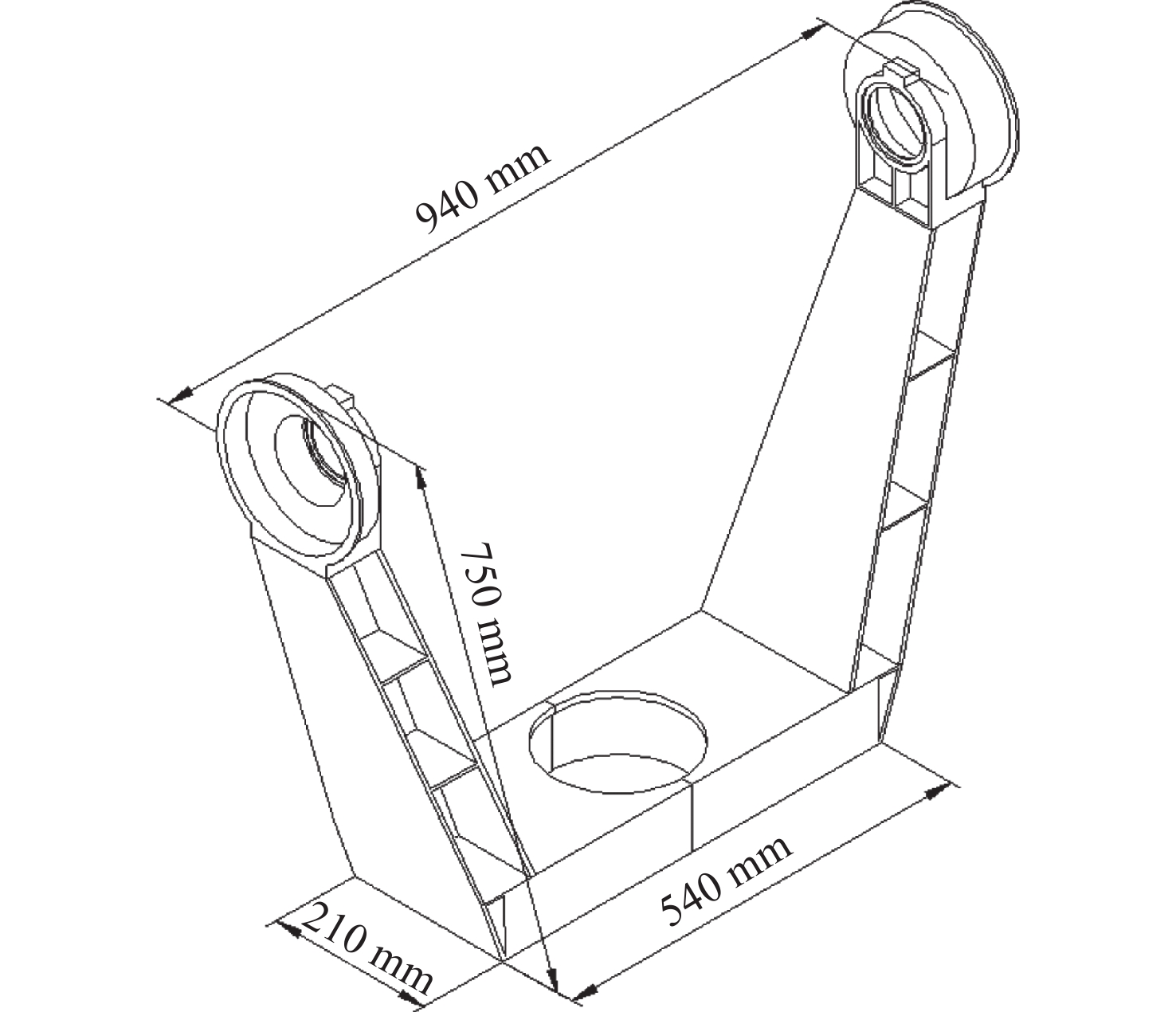

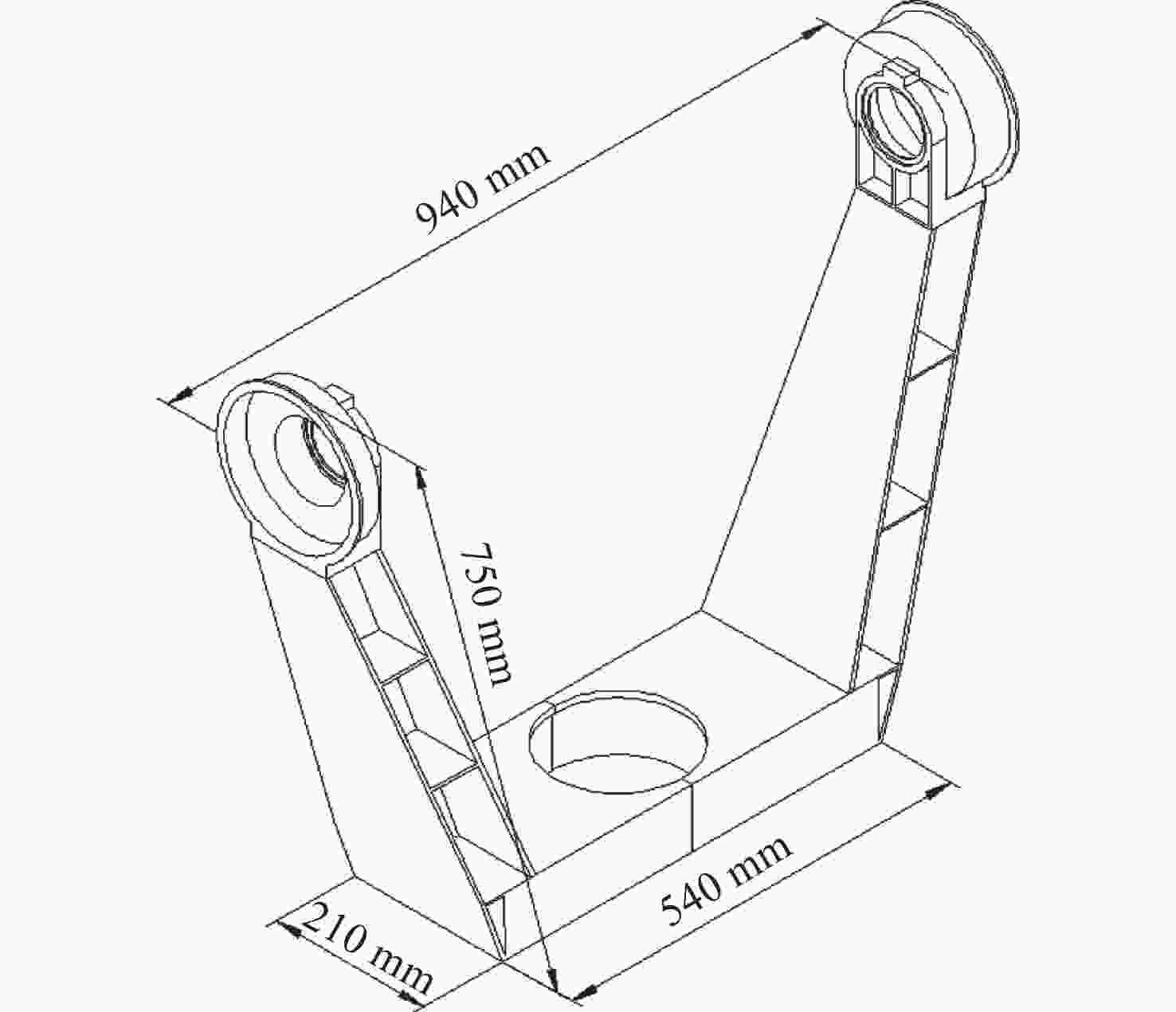

星载二维转台是空间相机等光电设备的主要承载机构,U型架是转台的关键支撑部件。为了对星载二维转台U型架进行结构优化与轻量化设计,研制高承载比和轻量化的星载二维转台,本文设计了一种用于星载二维转台的碳纤维复合材料U型架。首先,利用碳纤维复合材料代替钛合金材料,结合考虑工艺性,设计了一种变截面管状结构U型架。接着,按照基于铺层工艺的有限元建模方法对碳纤维U型架进行有限元建模与仿真分析。然后,试制U型架样机并通过模态试验验证有限元模型的准确性。最后,提出一种理论分析法、遗传算法、有限元法相结合的三级优化方法对碳纤维U型架铺层角度、铺层厚度与铺层顺序进行优化设计。结果表明:模态试验与仿真得到的U型架振型完全一致,频率相差在5%以内。初始设计的碳纤维U型架比钛合金U型架质量减少了45.7%,通过对复合材料铺层的优化设计,使U型架质量进一步减少了13.8%,固有频率提升了10.14%。本文所采用的复合材料建模与优化方法正确,设计的碳纤维U型架满足星载二维转台轻量化设计需求。

Abstract:Space-borne two-dimensional turntables are the main bearing mechanism of space cameras and other optoelectronic equipment, and the U-frame is the key supporting part of these turntables. In order to optimize the structure and lightweight design of the U-frame of the two-dimensional turntable and to develop a lightweight two-dimensional turntable with a high load-bearing ratio, we design a U-frame for the space two-dimensional turntable based on Carbon Fiber Reinforce Plastics (CFRP). First, a variable cross-section tubular structure U-frame was designed using carbon fiber composites instead of titanium alloy material considering the manufacturability. Then, according to the finite element modeling method based on the lay-up process, the carbon fiber U-frame was subjected to finite element modeling and simulation analysis. Then, a prototype U-frame was fabricated, and modal tests verified the accuracy of the finite element model. Finally, a three-level optimization method combining theoretical analysis, genetic algorithm, and the finite element method was proposed to optimize the design of carbon fiber U-frame ply angle, ply thickness, and ply sequence. The results indicate that the vibration patterns of the U-frame obtained from the modal test and simulation are identical and that the frequency difference is less than 5%. The initial design of the carbon fiber U-frame is 45.7% lighter than the titanium U-frame. Through the secondary optimization of the composite layup, the U-frame is further reduced in weight by 13.8%. Additionally, the intrinsic frequency of the U-frame is improved by 10.14%. It can be concluded that the composite modeling and optimization methods used in this paper are correct, and the designed carbon fiber U-frame meets the lightweight design requirements of space-born two-dimensional turntable.

-

表 1 U型架所用材料属性

Table 1. Properties of materials used for U-frame

材料 弹性

模量

E1/(MPa)弹性

模量

E2/(MPa)弹性

模量

E3/(MPa)剪切

模量

G/(MPa)泊松比

μ密度/

(g·cm−3)铝合金 71000 71000 71000 27000 0.3 2.7 碳纤维M40J 220000 8200 8200 5100 0.3 1.6 表 2 碳纤维U型架铺层方式

Table 2. CFRP U-frame layering method

铺层区域 单层厚度/mm 层数 总厚度/mm 铺层顺序 整体 0.133 27 3.591 [0/90/45/03/−45/0/0/−45/02/−45/03/45/0/90/0/45/0/90/0/902/0] 顶部加强区 过渡区1 30 3.990 [0/90/45/03/−45/0/0/−45/02/−45/03/45/0/90/0/45/0/90/0/902/0/−45/45/0] 过渡区2 33 4.389 [0/90/45/03/−45/0/0/−45/02/−45/03/45/0/90/0/45/0/90/0/902/0/−45/45/0/45/90/0/

−45/45/0]过渡区3 36 4.788 [0/90/45/03/−45/0/0/−45/02/−45/03/45/0/90/0/45/0/90/0/902/0/−45/45/0/45/90/0/−45/45/0/90/0/−45/45/90/0/−45/45/0] 底部加强区 过渡区1 31 4.123 [0/90/45/03/−45/0/0/−45/02/−45/03/45/0/90/0/45/0/90/0/902/0/−45/45/0/90] 过渡区2 35 4.655 [0/90/45/03/−45/0/0/−45/02/−45/03/45/0/90/0/45/0/90/0/902/0/45/90/0/0/−45/45/0/] 过渡区3 38 5.054 [0/90/45/03/−45/0/0/−45/02/−45/03/45/0/90/0/45/0/90/0/902/0/90/0/−45/45/90/0/0/

−45/45/0/90]表 3 碳纤维U型架模态仿真分析结果

Table 3. Modal simulation analysis results of CFRP U-frame

模态类型 阶次 仿真频率/Hz 仿真振型 约束模态 一阶 80.21 左臂左右摆 二阶 84.20 右臂左右摆 三阶 107.27 左臂前后摆 四阶 113.15 右臂前后摆 自由模态 一阶 80.30 两臂开合摆 二阶 168.11 两臂前后摆 三阶 248.81 两臂左右摆 表 4 钛合金U型架与碳纤维U型架对比分析

Table 4. Comparison of modal simulation analysis results for CFRP U-frame and titanium U-frame

项目 钛合金U型架 碳纤维U型架 质量/kg 19.90 10.80 厚度 5 mm(筋4 mm) 变厚度 一阶频率/Hz 83.60 80.21 最大应力/MPa 2.29 1.26 应力集中 明显 不明显 表 5 模态试验结果与有限元分析结果对比

Table 5. Comparison between modal test results and finite element analysis results

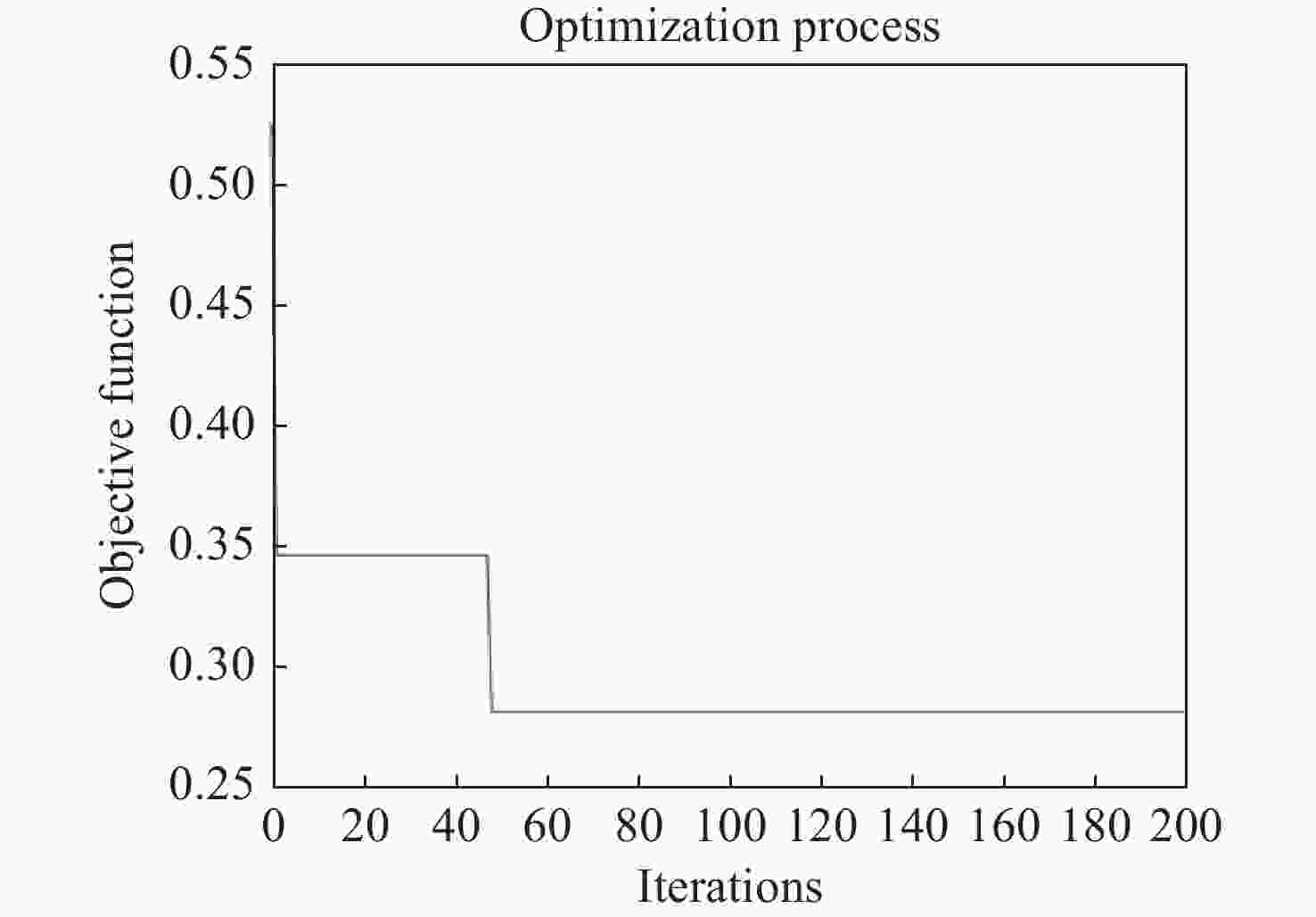

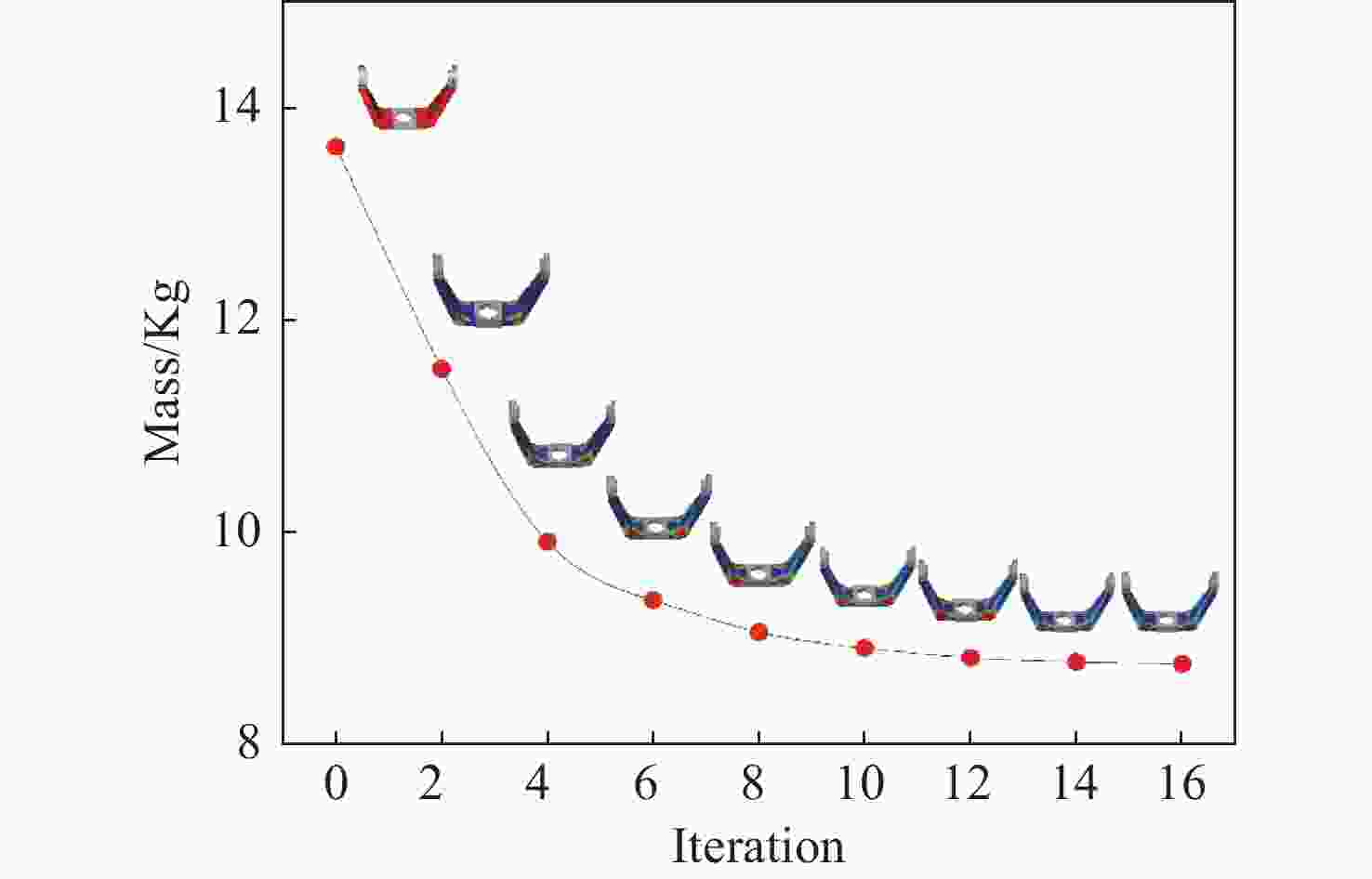

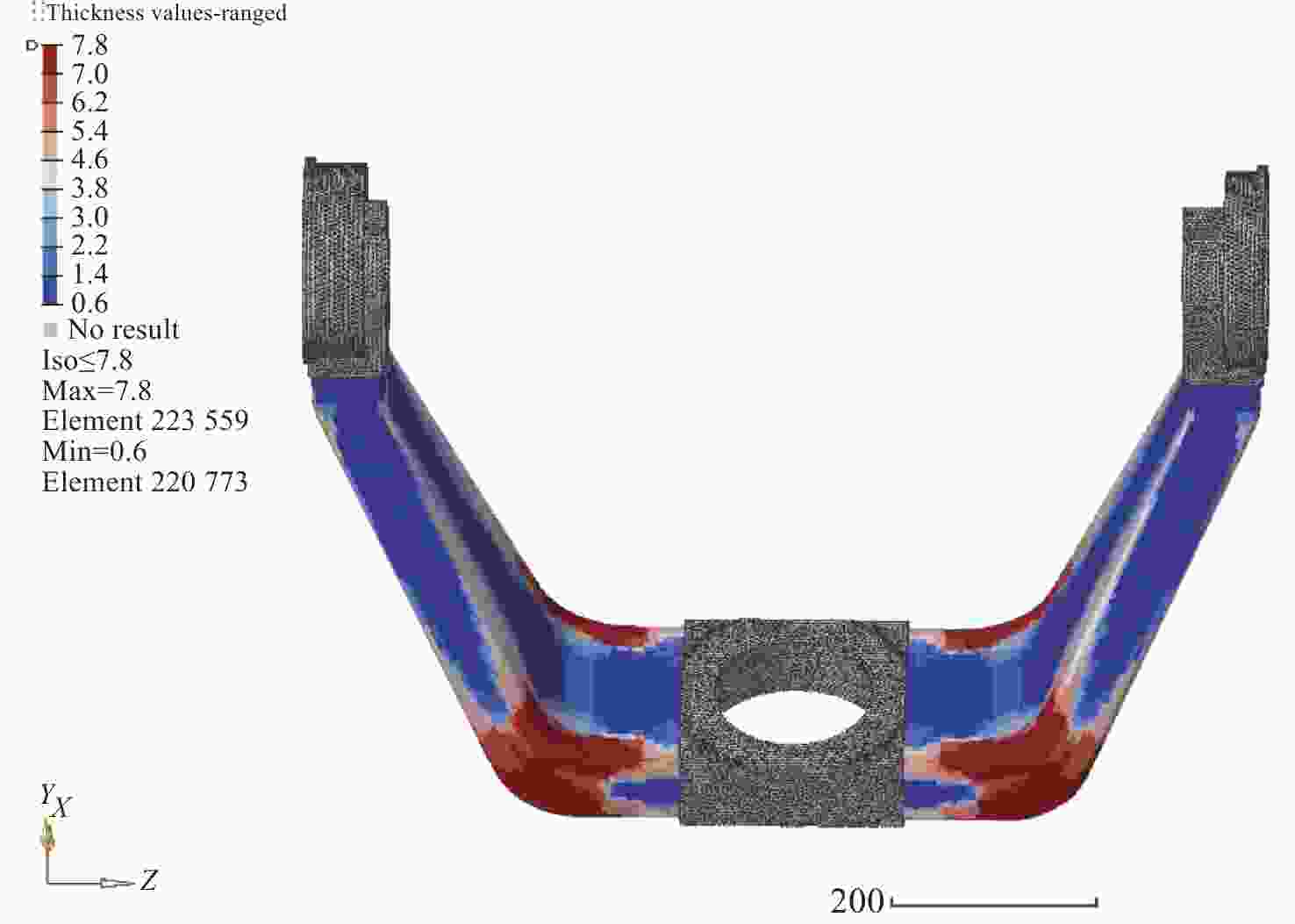

模态类型 阶次 仿真频率/Hz 试验频率/Hz 误差 约束模态 一阶 80.21 83.20 3.6% 二阶 84.20 87.90 4.2% 三阶 107.27 112.79 4.9% 四阶 113.15 117.39 3.6% 自由模态 一阶 80.30 84.42 4.9% 二阶 168.11 170.29 2.4% 三阶 248.81 252.76 3.3% 表 6 自由尺寸优化迭代过程

Table 6. Iterative process of free size optimization

迭代步 质量(kg) 优化前后

质量对比一阶固有

频率(Hz)优化前后固有

频率对比0 13.64 +20.82% 87.61 +8.44% 1 11.55 +6.49% 84.52 +5.10% 2 9.92 −8.15% 83.33 +3.74% 3 9.37 −13.24% 83.79 +4.27% 4 9.07 −16.02% 83.62 +4.08% 5 8.92 −17.41% 83.38 +3.80% 6 8.83 −18.24% 83.23 +3.63% 7 8.79 −18.61% 83.14 +3.52% 8 8.77 −18.80% 83.09 +3.47% 表 7 尺寸优化迭代过程

Table 7. Iterative process of size optimization

迭代步 质量

(kg)优化前后

质量对比一阶固有

频率(Hz)优化前后

固有频率对比0 12.20 +11.48% 107.65 +25.50% 1 10.38 +3.89% 95.65 +16.15% 2 9.25 −14.35% 83.29 +3.71% 3 9.32 −13.70% 86.42 +7.20% 4 9.28 −14.07% 86.52 +7.30% 5 9.31 −13.80% 87.33 +8.16% 表 8 U型架对比分析

Table 8. Comparative analysis of U-frames

项目 钛合金U型架 碳纤维U型架 铺层优化碳纤维U型架 质量 19.90 kg 10.80 kg 9.31 kg 一阶频率 83.60 Hz 80.21 Hz 89.26 Hz 最大应力 2.29 MPa 1.26 MPa 1.76 MPa -

[1] 孙景旭, 谢虹波, 李淑贤, 等. 轻小型全铝高分相机[J]. 中国光学(中英文),2023,16(6):1450-1462. doi: 10.37188/CO.2023-0062SUN J X, XIE H B, LI SH X, et al. All-aluminum high-resolution camera with lightweight and compact size[J]. Chinese Optics, 2023, 16(6): 1450-1462. (in Chinese). doi: 10.37188/CO.2023-0062 [2] HU Q L, LI ZH H, YANG L, et al. Overview of research on space laser communication tracking and pointing technology[J]. Chemical Engineering Transactions, 2015, 46: 1015-1020. [3] 张永强, 刘朝晖, 李治国, 等. 空间二维转台照准架的结构优化设计[J]. 红外与金宝搏188软件怎么用 工程,2017,46(S1):S113003.ZHANG Y Q, LIU ZH H, LI ZH G, et al. Optimum structural design for collimation frame of space-based two-dimensional turntable[J]. Infrared and Laser Engineering, 2017, 46(S1): S113003. (in Chinese). [4] 李威, 郭权锋. 碳纤维复合材料在航天领域的应用[J]. 中国光学,2011,4(3):201-212.LI W, GUO Q F. Application of carbon fiber composites to cosmonautic fields[J]. Chinese Optics, 2011, 4(3): 201-212. (in Chinese). [5] 李欣, 宋绮梦, 张学强, 等. 金宝搏188软件怎么用 加工碳纤维增强复合材料及其在航空航天领域应用[J]. 中国金宝搏188软件怎么用 ,2024,51(4):0402101. doi: 10.3788/CJL231358LI X, SONG Q M, ZHANG X Q, et al. Laser processing of carbon fiber reinforced polymer composites and their application in aerospace field[J]. Chinese Journal of Lasers, 2024, 51(4): 0402101. (in Chinese). doi: 10.3788/CJL231358 [6] 彭超义, 杜刚, 曾竟成, 等. 大载荷下空间桁架结构主承力用碳/环氧推力管的重量优化设计[J]. 玻璃钢/复合材料,2003(6):33-35,21.PENG CH Y, DU G, ZENG J CH, et al. Weight optimum design for primary load bearing carbon/epoxy tubes in space truss structure under large loads[J]. Fiber Reinforced Plastics/Composite, 2003(6): 33-35,21. (in Chinese). [7] 李威, 刘宏伟, 郭权锋, 等. 空间相机主次镜间的薄壁筒和支杆组合支撑结构[J]. 光学 精密工程,2010,18(12):2633-2641.LI W, LIU H W, GUO Q F, et al. Combined supporting structure of thin wall joint cylinder and supporting bar between primary mirror and second mirror in space camera[J]. Optics and Precision Engineering, 2010, 18(12): 2633-2641. (in Chinese). [8] 郭疆, 邵明东, 王国良, 等. 空间遥感相机碳纤维机身结构设计[J]. 光学 精密工程,2012,20(3):571-578. doi: 10.3788/OPE.20122003.0571GUO J, SHAO M D, WANG G L, et al. Design of optical-mechanical structure made of CFC in space remote sensing camera[J]. Optics and Precision Engineering, 2012, 20(3): 571-578. (in Chinese). doi: 10.3788/OPE.20122003.0571 [9] 王智. 基于碳纤维复合材料的月基极紫外相机照准架结构设计[J]. 中国光学,2012,5(6):590-595.WANG ZH. Design of collimation frame structure for lunar-based extreme ultraviolet camera based on carbon fiber reinforced plastics[J]. Chinese Optics, 2012, 5(6): 590-595. (in Chinese). [10] 陈卓, 胡庆龙, 李朝辉. 基于碳纤维框架天基目标探测二维跟踪转台结构优化[J]. 光学 精密工程,2021,29(3):547-557. doi: 10.37188/OPE.20212903.0547CHEN ZH, HU Q L, LI ZH H. Structural optimization of 2-D tracking turntable with carbon fiber framework for spatial target detection[J]. Optics and Precision Engineering, 2021, 29(3): 547-557. (in Chinese). doi: 10.37188/OPE.20212903.0547 [11] 方献军, 徐自立, 熊春明. OptiStruct及HyperStudy优化与工程应用[M]. 北京: 机械工业出版社, 2021.FANG X J, XU Z L, XIONG CH M. OptiStruct and HyperStudy Optimization and Engineering Application[M]. Beijing: China Machine Press, 2021. (in Chinese). [12] 李先阳, 刘彬, 于雅琳, 等. 碳纤维复杂构件LCM成型工艺技术发展综述[J]. 复合材料科学与工程,2023(11):116-121.LI X Y, LIU B, YU Y L, et al. A review of the development of LCM forming technology for carbon fiber complex components[J]. Composites Science and Engineering, 2023(11): 116-121. (in Chinese). [13] 贾振元, 付饶, 王福吉. 碳纤维复合材料构件加工技术进展[J]. 机械工程学报,2023,59(19):348-374. doi: 10.3901/JME.2023.19.348JIA ZH Y, FU R, WANG F J. Research advance review of machining technology for carbon fiber reinforced polymer composite components[J]. Journal of Mechanical Engineering, 2023, 59(19): 348-374. (in Chinese). doi: 10.3901/JME.2023.19.348 [14] 胡宁, 赵丽滨. 航空航天复合材料力学[M]. 北京: 科学出版社, 2021.HU N, ZHAO L B. Mechanics of Aerospace Composite Materials[M]. Beijing: Science Press, 2021. (in Chinese). [15] 黄成磊, 范庆明, 刘红军, 等. 利用遗传算法的太阳能复合材料机翼结构尺寸优化设计[J/OL]. 机械科学与技术, 2023: 1-8. https://doi.org/10.13433/j.cnki.1003-8728.20230289.HUANG CH L, FAN Q M, LIU H J, et al. Size optimization design of solar composite wing structure using genetic algorithm[J/OL]. Mechanical Science and Technology for Aerospace Engineering, 2023: 1-8. https://doi.org/10.13433/j.cnki.1003-8728.20230289. (in Chinese). [16] 孙鹏文, 侯战华, 岳彩宾, 等. 基于遗传算法的风力机叶片结构铺层厚度优化[J]. 太阳能学报,2016,37(6):1566-1572. doi: 10.3969/j.issn.0254-0096.2016.06.032SUN P W, HOU ZH H, YUE C B, et al. Ply thickness optimization of wind turbine blade based on genetic algorithm[J]. Acta Energiae Solaris Sinica, 2016, 37(6): 1566-1572. (in Chinese). doi: 10.3969/j.issn.0254-0096.2016.06.032 [17] 张景源, 陈北北, 杨永兴, 等. 融合遗传算法和BP神经网络的光斑定位方法[J]. 中国光学(中英文),2023,16(2):407-414. doi: 10.37188/CO.2022-0084ZHANG J Y, CHEN B B, YANG Y X, et al. Positioning algorithm for laser spot center based on BP neural network and genetic algorithm[J]. Chinese Optics, 2023, 16(2): 407-414. (in Chinese). doi: 10.37188/CO.2022-0084 [18] 严君. 基于OptiStruct碳纤维复合材料薄壁结构优化设计研究[D]. 太原: 中北大学, 2012.YAN J. Research on optimization design of carbon fiber composite thin-walled structure based on OptiStruct[D]. Taiyuan: North University of China, 2012. (in Chinese). [19] 董新洪, 孙鹏文, 张兰挺, 等. 风力机叶片铺层参数多目标优化设计[J]. 机械工程学报,2022,58(4):165-173. doi: 10.3901/JME.2022.04.165DONG X H, SUN P W, ZHANG L T, et al. Multi-objective optimization of ply parameters for wind turbine blade[J]. Journal of Mechanical Engineering, 2022, 58(4): 165-173. (in Chinese). doi: 10.3901/JME.2022.04.165 [20] 张娜, 姚树燕, 马钜, 等. 复合材料薄板的成型固化收缩变形研究[J]. 玻璃钢/复合材料,2009(4):24-26,31.ZHANG N, YAO SH Y, MA J, et al. Study on the shrinkage deformation of thin composite laminates during curing process[J]. Fiber Reinforced Plastics/Composite, 2009(4): 24-26,31. (in Chinese). [21] 王轩, 赵晨起. 弹载光学系统复合材料支撑结构低热膨胀优化[J]. 红外与金宝搏188软件怎么用 工程,2023,52(5):20220742. doi: 10.3788/IRLA20220742WANG X, ZHAO CH Q. Low thermal expansion optimization of composite support structure for missile-borne optical system[J]. Infrared and Laser Engineering, 2023, 52(5): 20220742. (in Chinese). doi: 10.3788/IRLA20220742 [22] 中国航空工业集团公司复合材料技术中心. 航空复合材料技术[M]. 北京: 航空工业出版社, 2013.AVIC COMPOSITE CO. Aviation Composite Material Technology[M]. Beijing: Aviation Industry Press, 2013. (in Chinese). -

下载:

下载: