Laser micro angular deviation measurement system

-

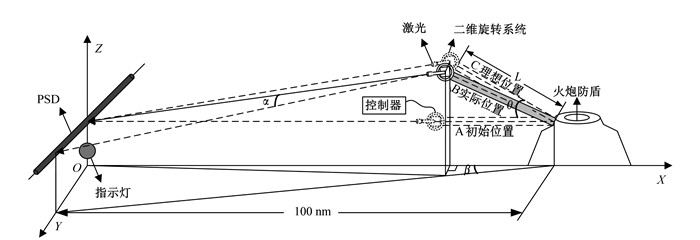

摘要: 针对火炮出厂前的校瞄工作存在自动化程度不高、测试结果分辨率和精度低的缺点,设计了一种新型金宝搏188软件怎么用 微角偏移测试校瞄系统。该系统由位置灵敏探测器(PSD)、准直平行金宝搏188软件怎么用 管与二维精密旋转控制器构成。采用光电转换和信号处理技术,可实时获取火炮身管轴线的微角偏移量;利用相对简单的方法完成了高精度的测试,有效地改善了传统校瞄方法的不足。实验测试结果表明,该系统可在炮管仰角0°~70°范围内全程测试微角偏移量,其分辨率可达到0.001°,可广泛应用于不同口径火炮身管轴线的校瞄工作中。

-

关键词:

- 校瞄 /

- 微角偏移 /

- 金宝搏188软件怎么用 /

- 位置灵敏探测器 (PSD)

Abstract: There are some shortcomings in aiming correction before the artillery leaves the factory, just like the low degree of automation, the low resolution and accuracy. Aiming at these problems, we design a novel laser micro angular deviation measurement and proofread aiming system. The system consists of position sensitive detector (PSD), collimating parallel laser tube and two-dimensional precision spin controller, and the micro angle offset of artillery bore can be acquired in real-time using the photoelectric conversion and signal processing technology. The traditional proofread aiming method can be improved effectively using relatively simple means to complete the high precision measurement. Experimental test results show that the system can detect the micro angle deviation with the barrel elevation range of 0°~70° in the whole course, and its resolution can reach 0.001°. It can be widely used to proofread aiming with different caliber artillery bore.-

Key words:

- proofread aiming /

- micro angular deviation /

- laser /

- position sensitive detector (PSD)

-

表 1 微角偏移测试系统与炮口瞄准仪结果对比

Table 1. Comparison between micro angular deviation measurement system and aiming sight at muzzle

炮管角度/(°) 金宝搏188软件怎么用 微角偏移测试结果平均值/(°) 米哈仪微角偏移测试结果平均值/(°) 上行程 下行程 上行程 下行程 12 -0.003 -0.005 0 0 24 -0.010 -0.012 0 -0.01 36 -0.021 -0.023 0 -0.02 48 -0.036 -0.037 -0.03 -0.04 60 -0.060 -0.061 -0.03 -0.04 69 -0.078 -0.079 -0.03 -0.04 表 2 微角偏移测试系统与炮口瞄准仪结果不确定度对比

Table 2. Comparison of uncertainly in measurement between the micro angular offset test system and aiming sight at muzzle

炮管角度/(°) 金宝搏188软件怎么用 微角偏移测试结果不确定度 米哈仪微角偏移测试结果不确定度 12 1.528×10-3 0.6×10-2 24 1.528×10-3 0.949×10-2 36 1.528×10-3 1.732×10-2 48 0.913×10-3 0.548×10-2 60 0.913×10-3 0.548×10-2 69 0.913×10-3 0.548×10-2 -

[1] 迟铁. 炮口偏移量测量方法研究[D]. 长春: 长春理工大学, 2009.CHI T. Study of measurement method of gun-muzzle of-set[D]. Changchun:Changchun University of Science and Technology, 2009.(in Chinese) [2] 徐诚, 王亚平.火炮与自动武器动力学[M].北京:北京理工大学出版社, 2006.XU CH, WANG Y P. Dynamics of Artillery and Automatic Weapons[M]. Beijing:Beijing Institute of Technology Press, 2006. (in Chinese) [3] 杨树青, 张惠民, 包俊彦, 等.火炮测量中使用经纬仪与炮口瞄准仪的分析[J].测试技术学报, 2002, 16(3):184-188. http://www.cnki.com.cn/Article/CJFDTOTAL-CSJS200203006.htmYANG SH Q, ZHANG H M, BAO J Y, et al.. The Analyses of measuring gun by using teodolite and aiming sight at muzzle[J]. J. Test and Measurement Technology, 2002, 16(3):184-188.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-CSJS200203006.htm [4] 方仲彦, 殷纯永, 梁晋文.高精度金宝搏188软件怎么用 准直技术的研究[J].航空计测技术, 1997(1):3-6. http://www.cnki.com.cn/Article/CJFDTOTAL-HKJC199701000.htmFANG ZH Y, YIN CH Y, LIANG J W. Study on high accuracy laser alignment technique[J]. Aviation Metrology & Measurement Technology, 1997(1):3-6.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-HKJC199701000.htm [5] KAWASAKI A, GOTO M. On the position response of a position[J]. Sensors & Actuators A Physical, 1990, 22(89):534-537. [6] 孟翔飞, 王昌明, 何博侠, 等.火炮身管静态多参数测量系统的研究[J].南京理工大学学报 (自然科学版), 2013, 37(1):117-132. http://www.cnki.com.cn/Article/CJFDTOTAL-NJLG201301021.htmMENG X F, WANG C M, HE B X, et al.. Static multi-parameter measuring system for gun barrel[J]. J. Nanjing University of Science and Technology, 2013, 37(1):117-132.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-NJLG201301021.htm [7] 李欣欣. 宏/微两级驱动的大行程高精度二维定位平台基础技术研究[D]. 杭州: 浙江大学, 2008.LI X X. Study of fundamental technologies for large range and high precision 2-D coarse/fine positioner[D]. Hangzhou:Zhejiang University, 2008.(in Chinese) [8] 吴赛燕.PSD的性能分析及其应用[J].机械工程与自动化, 2007(2):109-111. http://www.cnki.com.cn/Article/CJFDTOTAL-SXJX200702040.htmWU S Y. Analysis on properties of PSD and its application[J]. Mechanical Engineering & Automation, 2007(2):109-111.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-SXJX200702040.htm [9] 朱尚明.位置敏感检测器PSD及其应用研究[J].仪表技术与传感器, 1996(2):39-40. http://www.cnki.com.cn/Article/CJFDTOTAL-YBJS199602010.htmZHU SH M. A Position Sensitive Detector (PSD) and its applications[J]. Instrument Technique and Sensor, 1996(2):39-40.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-YBJS199602010.htm [10] 黄继鹏, 王延杰, 孙宏海, 等.金宝搏188软件怎么用 光斑位置精确测量系统[J].光学精密工程, 2013, 21(4):841-848. doi: 10.3788/OPE.HUANG J P, WANG Y J, SUN H H, et al.. Precise position measuring system for laser spots[J]. Opt. Precision Eng., 2013, 21(4):841-848.(in Chinese) doi: 10.3788/OPE. [11] 王立军, 彭航宇, 张俊.大功率半导体金宝搏188软件怎么用 合束进展[J].中国光学, 2015, 8(4):517-534. doi: 10.3788/co.WANG L J, PENG H Y, ZHANG J. Advance on high power diode laser coupling[J]. Chinese Optics, 2015, 8(4):517-534.(in Chinese) doi: 10.3788/co. [12] 宋薇, 章亚男, 沈林勇.高功率金宝搏188软件怎么用 装置中靶的定位调试[J].光学精密工程, 2015, 23(2):520-527. http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201502027.htmSONG W, ZHANG Y N, SHEN L Y. Target positioning in high power laser device[J]. Opt. Precision Eng., 2013(8):8-16.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201502027.htm [13] 许忠保, 王宝龙, 刘力.位置敏感器件PSD抗干扰方法研究[J].仪表技术与传感器, 2000, 8:39-40. http://www.cnki.com.cn/Article/CJFDTOTAL-YBJS200008014.htmXU ZH B, WANG B L, LIU L. Study on a method to eliminate the disturbance of PSD[J]. Instrument Technique and Sensor, 2000, 8:39-40.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-YBJS200008014.htm [14] 张旭峰.大学物理实验[M].北京:机械工业出版社, 2013.ZHANG X F. College Physics Experiment[M]. Beijing:China Machine Press, 2013. [15] 盛德仁, 沈柯.金宝搏188软件怎么用 不稳定性的平均场理分析[J].金宝搏188软件怎么用 杂志, 1987, 1:1-6. http://www.cnki.com.cn/Article/CJFDTOTAL-JGZZ198701000.htmSHENG D R, SHEN K. The analysis of mean-field theory of the laser instability[J]. Laser Journal, 1987, 1:1-6.(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-JGZZ198701000.htm [16] 马宏, 王金波. 仪器精度理论[M]. 北京: 北京航空航天大学出版社, 2009.MA H, WANG J B. Instrument Accuracy Theory[M]. Beijing:Beihang University Press.(in Chinese) -

下载:

下载: