Definition and application of easily measurable aspheric surfaces

doi: 10.3788/CO.20171002.0256

-

摘要: 本文提出了一种新型、易于用传统光学干涉仪测量的非球面.该非球面的检测主要基于Zemax光学程序软件设计的多重配置特性.第一配置为易于测量非球面, 第二配置为采用平行平面玻璃板或单透镜作为零位校正器, 用于检测第一配置的非球面.本文通过一些实例, 说明了易测量非球面检测技术的应用和优势, 证实了与圆锥或普通非球面相比, 易测量非球面更易于操作与检测, 同时有利于减小光学像差.Abstract: This paper presents a new kind of "Easily Measurable Aspheric Surfaces"(EMAS), which could be easily measured by a traditional optical interferometer. The measurement of EMAS is mainly based on using the multi-configuration feature in Zemax software. The first configuration represents the optical system with EMAS, and the second configuration represents the setup, using a parallel planes glass plate or a single lens as a null corrector to measure the aspheric surface used in the first configuration. The applications and advantages of this technique are illustrated by many examples, which could confirm the ease of manipulating and testing this kind of surfaces, compared with conical or general aspheric surfaces. It can also show its competence in minimizing the optical aberrations.

-

Key words:

- easily measurable aspheric surfaces /

- interferometer /

- null test

-

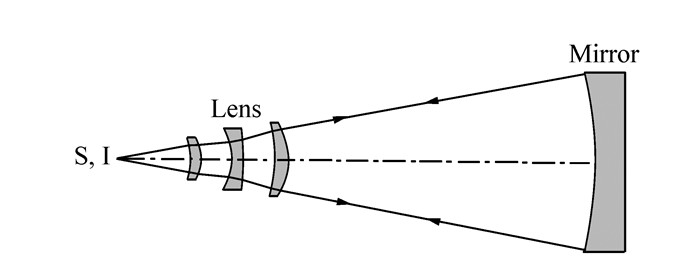

Figure 1. Schematics of Shafer null corrector[10]

Figure 2. Schematics of Offner null corrector[10]

Table 1. Parameters of the two configurations:Config 1 for the objective lens; Config 2 for the test setup

Active 1/2 Config 1 Config 2 Active 1/2 Config 1 Config 2 1:wave 1 8 μm 0.632 8 μm 17:THIC 5 10.00 81.2754 2:wave 2 10 μm 0.632 8 μm 18:SDIA 1 25.00 40.00 3:wave 3 12 μm 0.632 8 μm 19:SDIA 2 24.00 40.00 4:CRVT 1 0.015 6 0.000 20:SDIA 3 12.00 25.00 5:CRVT 2 0.013 8 0.000 21:SDIA 4 10.00 40.00 6:CRVT 3 0.056 6 0.015 6 22:SDIA 5 10.00 40.00 7:CRVT 4 0.057 5 0.000 23:APER 0 1.200 0.400 8:CRVT 5 0.057 5 0.000 24:CONN 1 0.228 2 0.000 9:GLSS 1 GERMANIUM BK7 25:CONN 3 0.000 0.228 2 10:GLSS 3 GERMANIUM MIRROR 26:YFIE 1 0.000 0.000 11:GLSS 4 BK7 27:YFIE 2 4.000 0.000 12:THIC 0 1.00×1010 -81.275 4 28:YFIE 3 6.500 0.000 13:THIC 1 3.50 10.914 7 29:PAR1 1 1.003×10-3 0.000 14:THIC 2 56.096 5 17.124 1 30:PAR2 1 5.148×10-8 0.000 15:THIC 3 2.600 -17.124 1 31:PAR1 3 0.000 1.003×10-3 16:THIC 4 0.000 -10.914 7 32:PAR2 3 0.000 5.148×10-8 Table 2. Final lens objective design in Zemax software

Surf:Type Radius/mm Thickness/mm Glass Semi-Diameter/mm Conic Par 1 Par 2 OBJ Standard Infinity Infinity Infinity 0.000 STO Even Asphere 64.293 5 3.500 GERMNIUM 25.000 0.228 1.003×10-3 5.148×10-8 2 Standard 72.414 9 56.096 24.000 0.000 3 Even Asphere 17.657 8 2.600 GERMNIUM 12.000 0.000 0.000 0.000 4 Standard 17.382 0 0.000 10.000 0.000 5 Standard 17.382 0 10.000 10.000 0.000 IMA Standard Infinty - 6.257 0.000 Table 3. Final null test of the EMAS used in the objective lens design

Surf:Type Radius/mm Thickness/mm Glass Semi-diameter/mm Conic Par 1 Par 2 OBJ Standard Infinity -81.275 Infinity 0.000 STO Standard Infinity 10.915 BK7 40.000 0.000 2 Standard Infinity 17.124 40.000 0.000 3 Even Asphere 64.294 -17.124 MIRROR 25.000 0.228 1.003×10-3 5.148×10-8 4 Standard Infinity -10.915 BK7 40.000 0.000 5 Standard Infinity 81.275 40.000 0.000 IMA Standard Infinty - 2.260×10-4 0.000 Table 4. Parameters of the two configurations:Config 1 for the objective lens; Config 2 for the test setup

Active 1/2 Config 1 Config 2 Active 1/2 Config 1 Config 2 1:wave 1 8 μm 0.632 8 μm 19:SDIA 1 25.00 18.000 2:wave 2 10 μm 0.632 8 μm 20:SDIA 2 24.00 20.000 3:wave 3 12 μm 0.632 8 μm 21:SDIA 3 12.00 25.000 4:CRVT 1 0.017 4 mm -0.029 9 mm 22:SDIA 4 10.00 20.000 5:CRVT 2 0.012 0 mm -1.942×10-3 mm 23:SDIA 5 10.00 18.000 6:CRVT 3 0.055 3 mm -0.012 0 mm 24:APER 0 1.200 0.600 7:CRVT 4 0.055 8 mm -1.942×10-3 mm 25:CONN 2 0.7413 0.000 8:CRVT 5 0.055 8 mm -0.029 9 mm 26:CONN 3 0.000 0.741 3 9:GLSS 1 GERMANIUM BK7 27:YFIE 1 0.000 0.000 10:GLSS 3 GERMANIUM MIRROR 28:YFIE 2 4.000 0.000 11:GLSS 4 BK7 29:YFIE 3 6.500 0.000 12:THIC 0 1.00×1010 1.00×1010 30:PAR1 2 8.314×10-4 0.000 13:THIC 1 3.500 0 10.000 31:PAR2 2 -7.988×10-9 0.000 14:THIC 2 56.137 5 20.000 32:PAR3 2 3.421×10-12 0.000 15:THIC 3 2.600 0 -20.000 33:PAR1 3 0.000 8.314×10-4 16:THIC 4 0.000 0 -10.000 34:PAR2 3 0.000 -7.988×10-9 17:THIC 5 10.000 -15.000 35:PAR3 3 0.000 3.421×10-12 18:THIC 6 0.000 -20.000 Table 5. Final lens objective design in Zemax software

Surf:Type Radius/mm Thickness/mm Glass Semi-diameter/mm Conic Par 1 Par 2 Par 3 OBJ Standard Infinity Infinity Infinity 0.000 STO Standard 57.465 3.500 GERMNIUM 25.000 0.000 2 Even Asphere 83.516 56.138 24.000 0.741 8.314×10-4 -7.988×10-9 3.421×10-12 3 Standard 18.096 2.600 GERMNIUM 12.000 0.000 4 Standard 17.918 0.000 10.000 0.000 5 Standard 17.918 10.000 10.000 0.000 6 Paraxial 0.000 6.268 20.000 0 IMA Standard Infinity - 6.268 0.000 Table 6. Final null test of the EMAS used in the objective lens design

Surf:Type Radius/mm Thickness/mm Glass Semi-diameter/mm Conic Par 1 Par 2 Par 3 OBJ Standard Infinity Infinity 0 0.000 STO Standard -33.418 10.000 BK7 18.000 0.000 2 Standard -514.865 20.000 20.000 0.000 3 Even Asphere -83.516 -20.000 MIRROR 25.000 0.741 8.314×10-4 -7.988×10-9 3.421×10-12 4 Standard -514.865 -10.000 BK7 20.000 0.000 5 Standard -33.418 -15.000 18.000 0.000 6 Paraxial -20.000 16.666 20.000 0 0 IMA Standard Infinity - 1.24×10-4 0.000 Table 7. Two configurations table, Config 1 for the collimating lens; Config 2 for the null test

Active 1/2 Config 1 Config 2 Active 1/2 Config 1 Config 2 1:CRVT 1 0.014 3 0.000 11:THIC 3 0.000 -10.000 2:CRVT 2 7.574×10-3 0.000 12:THIC 4 0.000 -8.378 3:CRVT 3 0.000 -7.574×10-3 13:THIC 5 0.000 -57.607 4:CRVT 4 0.000 0.000 14:CONN 1 3.851 5 0.000 5:CRVT 5 0.000 0.000 15:CONN 3 0.000 3.8515 6:GLSS 3 MIRROR 16:PAR1 1 -3.051×10-3 0.000 7:APER 0 40.000 31.000 17:PAR2 1 -6.735×10-8 0.000 8:THIC 0 1.00×1010 57.607 18:PAR1 3 0.000 -3.051×10-3 9:THIC 1 10.000 8.378 19:PAR2 3 0.000 -6.735×10-8 10:THIC 2 142.629 10.000 Table 8. Final collimating lens design in Zemax software

Surf:Type Radius/mm Thickness/mm Glass Semi-diameter/mm Conic Par 1 Par 2 OBJ Standard Infinity Infinity 0.000 0.000 STO Standard 70.141 10.000 BK7 20.000 0.000 2 Even Asphere 132.029 142.629 19.256 3.852 -3.051×10-3 -6.735×10-8 3 Standard Infinity 0.000 0.011 0.000 4 Standard Infinity 0.000 BK 0.011 0.000 5 Standard Infinity 0.000 0.011 0.000 IMA Standard Infinity - 0.011 0.000 Table 9. Final Null test of the EMAS used in the collimating lens design

Surf:Type Radius/mm Thickness/mm Glass Semi-diameter/mm Conic Par 1 Par 2 OBJ Standard Infinity 57.607 0.000 0.000 STO Standard Infinity 8.378 BK7 15.500 0.000 2 Standard Infinity 10.000 16.955 3 Even Asphere -132.029 -10.000 MIRROR 18.971 3.852 -3.051×10-3 -6.735×10-8 4 Standard Infinity -8.378 BK 16.955 0.000 5 Standard Infinity -57.607 15.499 0.000 IMA Standard Infinity - 2.397×10-3 0.000 -

[1] SCHULZ, GVNTER. Imaging performance of aspherics in comparison with spherical surfaces[J]. Applied Optics, 1987, 26(23):5118-5124. doi: 10.1364/AO.26.005118 [2] BRAUNECKER B, HENTSCHEL R, TIZIANI H. Advanced Optics Using Aspherical Elements[M]. Bellingham, USA:SPIE, 2008. [3] BRIERS J. DAVID. Optical testing:a review and tutorial for optical engineers[J]. Optics and Lasersin Engineering, 1999, 32:111-138. doi: 10.1016/S0143-8166(99)00062-7 [4] SHI T U, ET A L. Surface testing methods of aspheric optical elements[J].Chinese Optics, 2014, 7(1):26-46. [5] MALACARA, DANIEL. Optical Shop Testing[M]. New Jersey:John Wiley & Sons, 2007. [6] WANG X K. Compensation of misalignment error on testing aspheric surface by subaperture stitching interferometry[J]. Chinese Optics, 2013, 6(1):88-95. https://www.researchgate.net/publication/269456604_Compensation_of_misalignment_error_on_testing_aspheric_surface_by_subaperture_stitching_interferometry [7] OFFNER, ABE. A null corrector for paraboloidal mirrors[J]. Applied Optics, 1963, 2(2):153-155. doi: 10.1364/AO.2.000153 [8] BOTTEMA, MURK. Reflective correctors for the Hubble Space Telescope axial instruments[J]. Applied Optics, 1993, 32(10):1768-1774. doi: 10.1364/AO.32.001768 [9] OKA, KEITA, SCOTT SPARROLD. Asphere Design for Dummies[J]. SPIE, 2012, 8487:84870B. [10] BURGE, JAMES HOWARD. Advanced techniques for measuring primary mirrors for astronomical telescopes[D]. Arizona: University of Arizona, 1993. [11] DEVOE, CATHERINE ELLEN. Limitations on aspheric surface testing with simple null correctors[D]. Arizona: Optical Sciences Center, University of Arizona Tucson, 1989. [12] SASIAN J M. Optimum configuration of the offner null corrector. testing an F#/1 paraboloid[J]. SPIE, 1989, 1164:8-17. https://www.researchgate.net/publication/252870507_Optimum_Configuration_Of_The_Offner_Null_Corrector_Testing_An_F1_Paraboloid [13] MALACARA-HERN NDEZ, DANIEL, ZACAR AS MALACARA-ERN NDEZ. Handbook of Optical Design[M]. Florida:CRC Press, 2016. [14] Zemax Manual: Optical Design Program User's Guide[R]. Zemax, 2009. -

下载:

下载: