Optimization and analysis of a primary mirror for a laser incoherent combining system

-

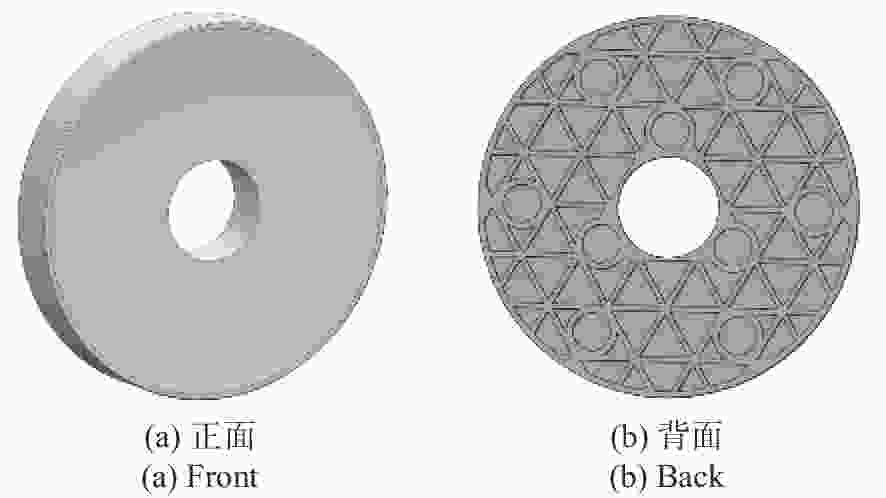

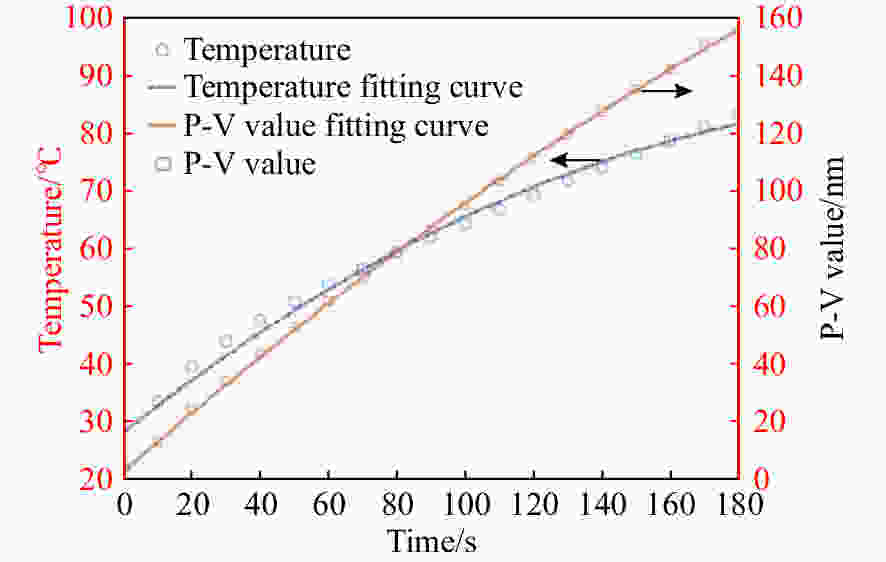

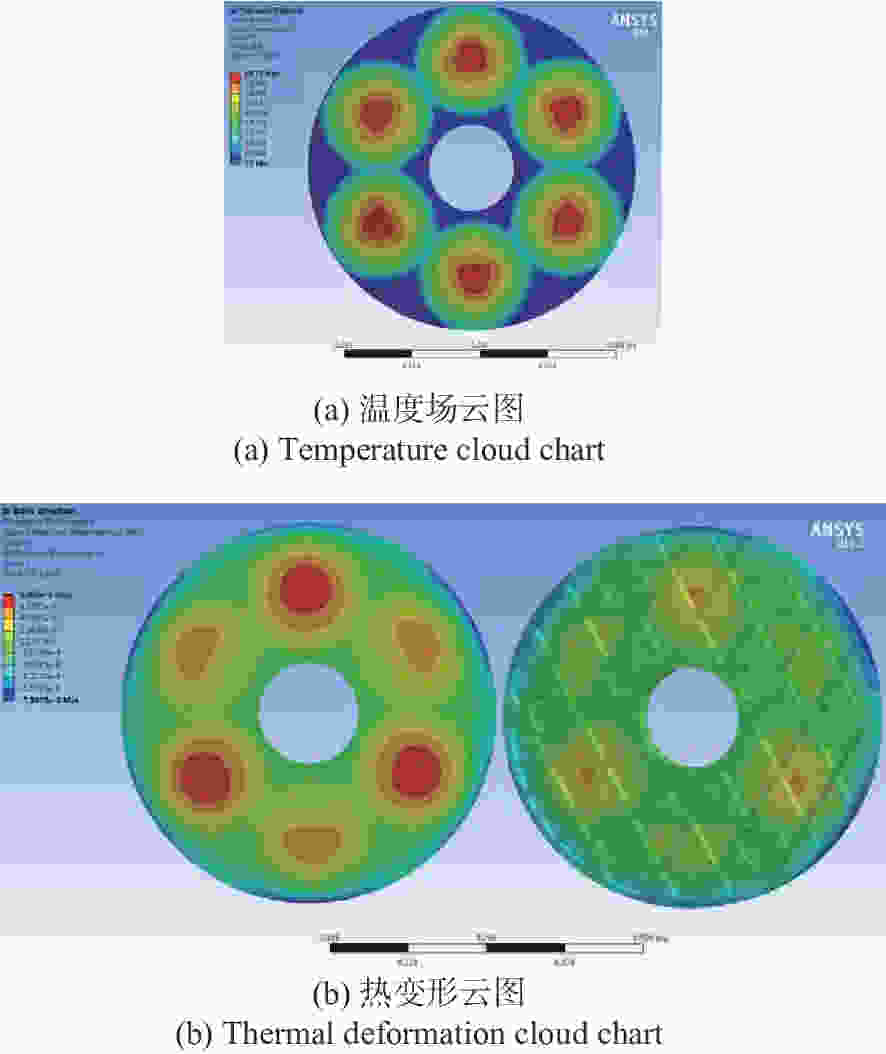

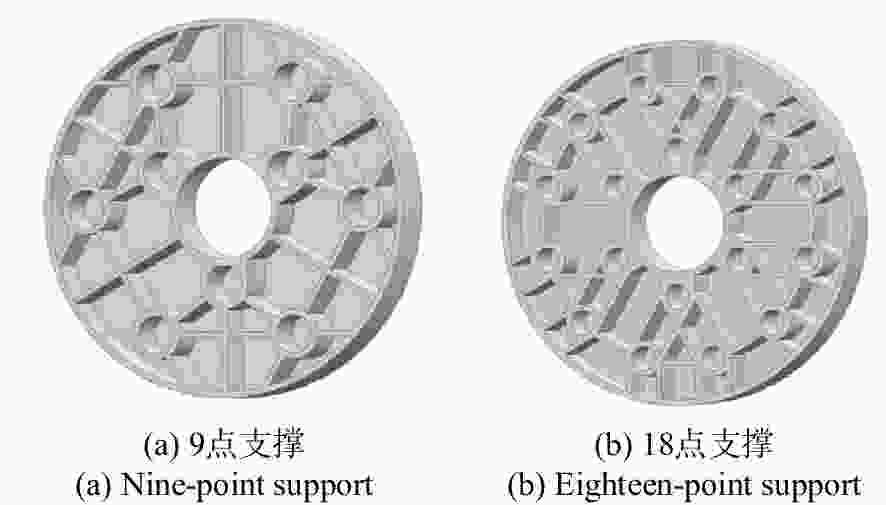

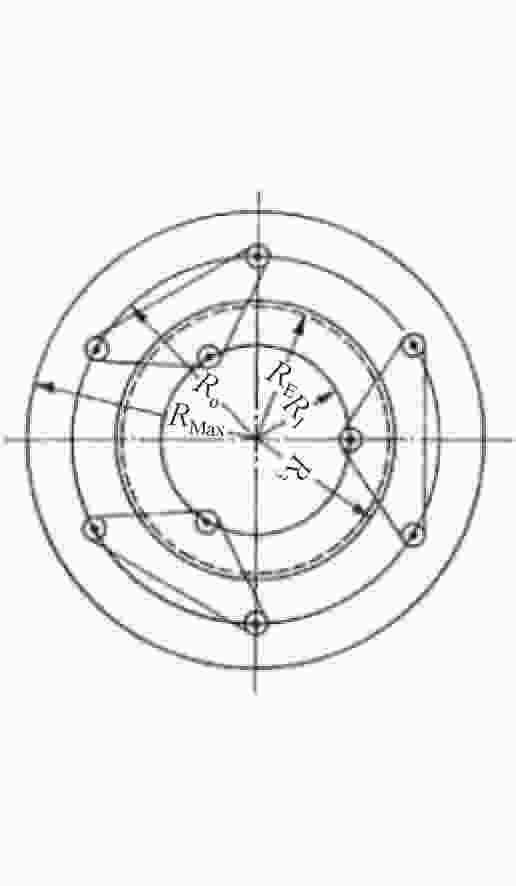

摘要: 本文对金宝搏188软件怎么用 空间合束主镜进行优化设计与分析,以抑制强金宝搏188软件怎么用 空间合束系统主镜热畸变,提高主镜面形精度。首先,对比分析了选择不同材料作为主镜基底的优缺点,从理论上初步确定了主镜材料、镜体厚度、支撑方式和轻量化结构形式;然后,利用有限元方法对空间合束主镜进行了热畸变分析,并结合热畸变结果对镜体结构形式进行拓扑优化设计;最后,对主镜进行重力、环境适应性和基频分析,验证设计的合理性。分析结果表明:6光合束主镜在单束10 kW金宝搏188软件怎么用 辐照下,随着辐照时间的增加,镜面温升值和P-V值逐渐增大;辐照3 min后初设计主镜表面温度达83.4 ℃,P-V值为155 nm,受镜体结构影响,辐照区内热畸变值不一致,差值约占镜面P-V值的1/6;为改善热畸变的不一致性,提高镜体强度,对主镜进行拓扑优化设计,优化后主镜轻量化达54.5%,辐照区热畸变一致性好,镜面热畸变量减小了近1/3;不同俯仰姿态下,主镜重力变形值基本相同,不足10 nm;环境温度的改变会引起主镜的镜面畸变和平移,稳态温差值越大,主镜面形P-V值和镜面平移量越大;模态分析显示主镜基频满足系统要求。本文研究结果将对金宝搏188软件怎么用 空间合束系统的设计提供依据。

-

关键词:

- 大功率金宝搏188软件怎么用 /

- 空间合束 /

- 主镜 /

- 金宝搏188软件怎么用 热畸变 /

- 轻量化设计

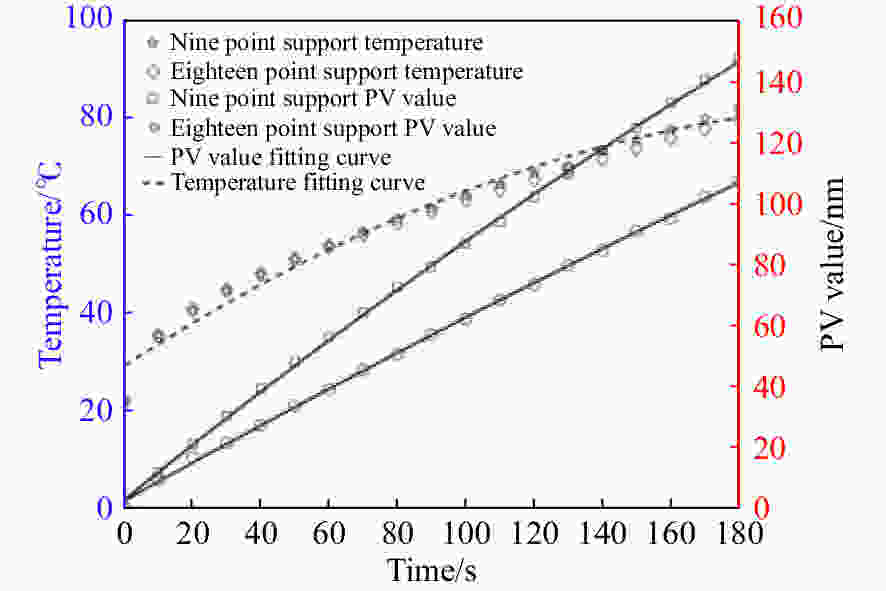

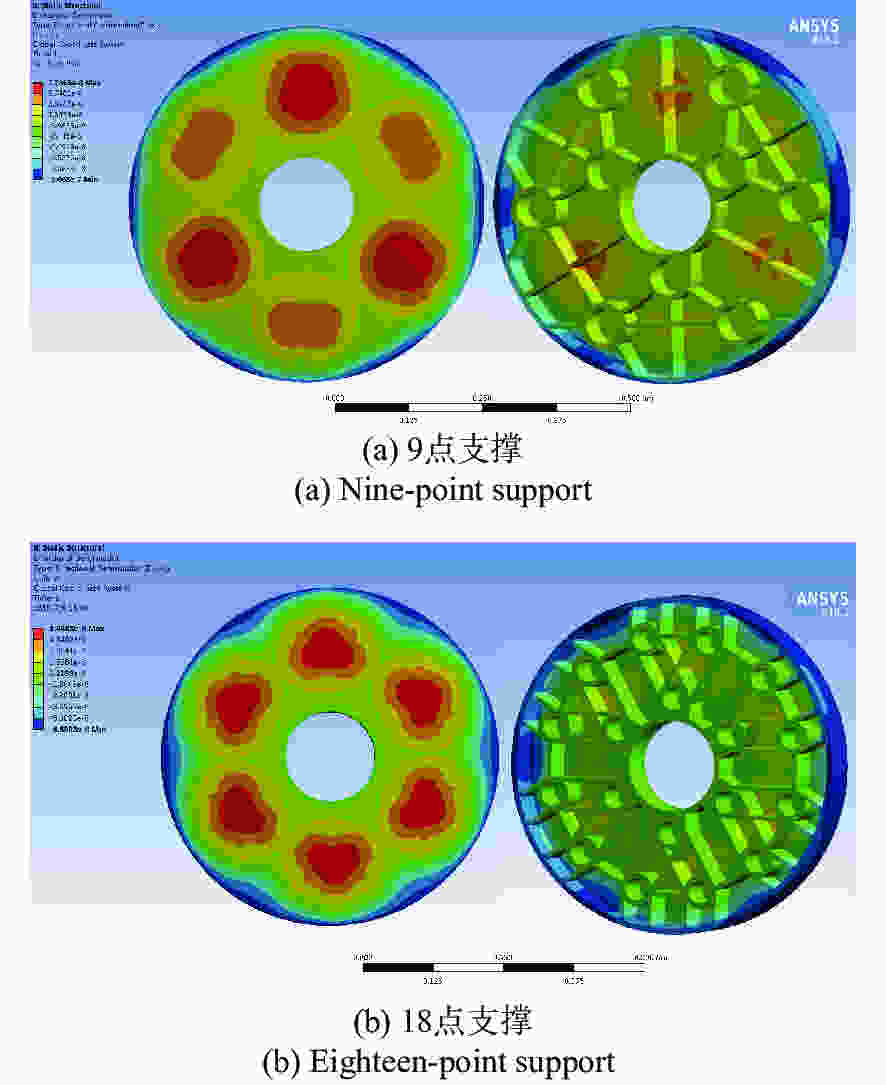

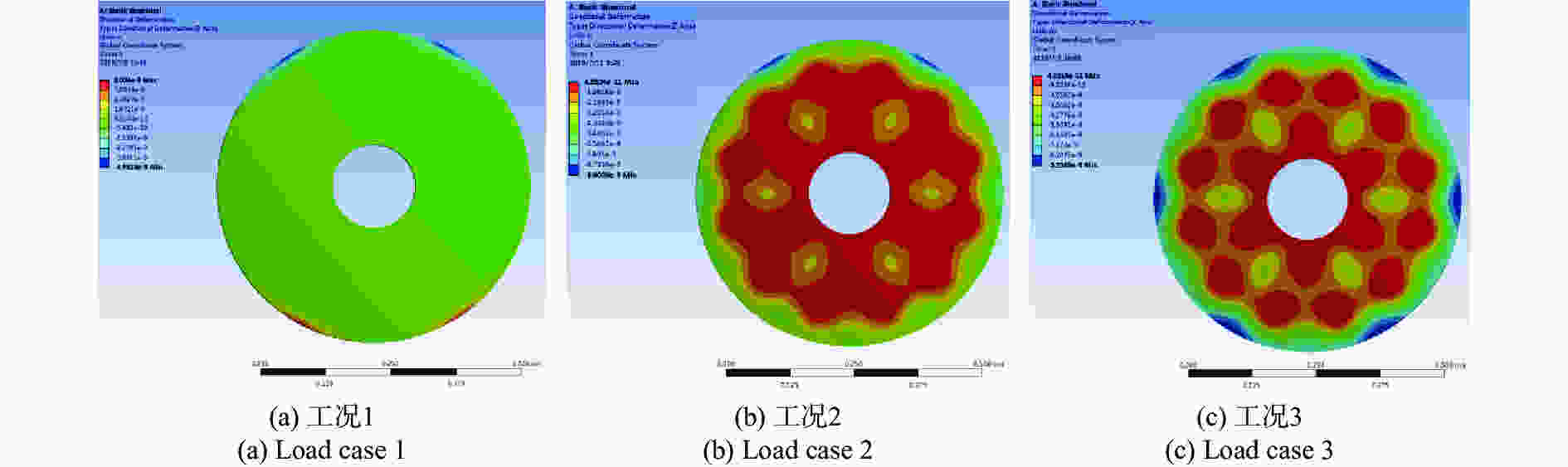

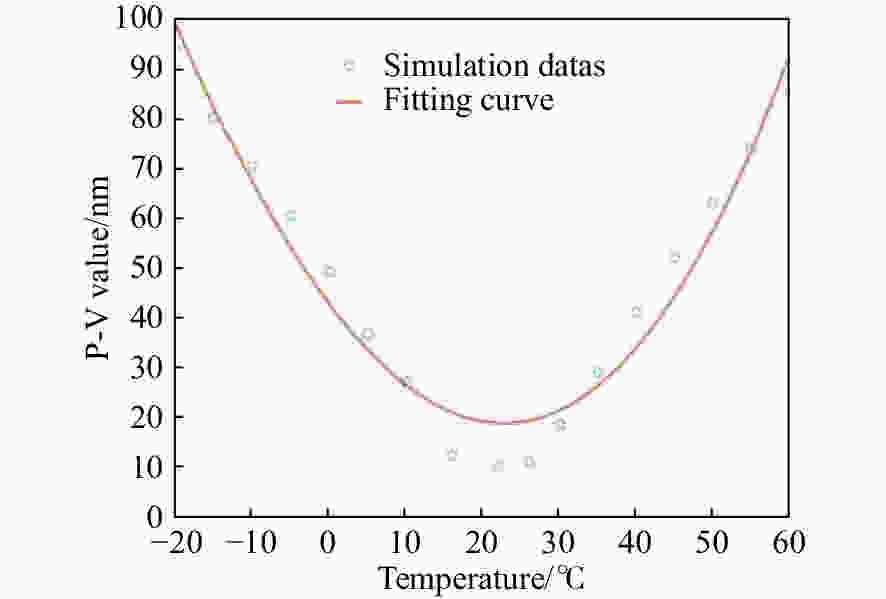

Abstract: A primary mirror for a high-power laser incoherent combining system was designed and analyzed. Firstly, the material and the thickness of the primary mirror, it's supporting way and it's lightweight scheme were determined through theoretical analysis. Then, the thermal deformation of the primary mirror was calculated by the finite element method, and the topology optimization was executed according to thermal deformation results. Finally, the impact of gravity, base frequency and ambient temperature on the P-V value of the primary mirror was analyzed. The calculation results show that the temperature rise ΔT and the P-V value of the primary mirror gradually increase when irradiated by six lasers with a power of 10 kW over a greater amount of time. When laser irradiation time reaches 3 min, the temperature rise ΔT and the P-V value of the unoptimized primary mirror are 83.4 ℃ and 155 nm respectively, resulting in thermal deformation values in the irradiated area that are inconsistently affecting by the structure. Its D-value was about 1/6 that of the primary mirror. After topology optimization, the lightweight rate of the primary mirror was 54.5%, the thermal deformation value in the laser-irradiated area was consistent, and the P-V value of the primary mirror reduced to 1/3. The gravity deformation value of the primary mirror at different pitching angles was basically the same and the maximum P-V value was less than 10 nm. The ambient temperature causes distortion and defocus aberration, and with an increase in ambient temperature, the aberration grows. Modal analysis shows that the base frequency of the primary mirror meets the system requirement. These conclusions have a referential value for high power laser incoherent combining systems.-

Key words:

- high power laser /

- incoherent combining /

- primary mirror /

- laser thermal deformation /

- light weight

-

表 1 常见主镜材料的热物理参数

Table 1. Main parameters of common primary mirror materials

材料 密度(g/cm3) 弹性模量(GPa) 比刚度(E/ρ:106) 比热C (J/kg∙℃) 热膨胀系数α(10−6/K) 热导率K(W/mK) 热畸变(α/K:10−8) 泊松比μ SiC 3.05 400 12.6 680 2.2 185 1.3 0.16 Zerodur 2.5 92 3.7 821 0.05 1.46 3.4 0.24 ULE 2.2 67 3.1 766 0.03 1.3 2.3 0.17 Be 1.85 280 15.1 1 925 11.4 160 7.2 0.05 熔石英 2.2 74 3.36 1 210 0.56 1.38 40.5 0.17 -

[1] FAN T Y. Laser beam combining for high-power, high-radiance sources[J]. IEEE Journal of Selected Topics in Quantum Electronics, 2005, 11(3): 567-577. doi: 10.1109/JSTQE.2005.850241 [2] LEGER J R, NILSSON J, HUIGNARD J P, et al. Introduction to the issue on laser beam combining and fiber laser systems[J]. IEEE Journal of Selected Topics in Quantum Electronics, 2009, 15(2): 237-239. doi: 10.1109/JSTQE.2009.2015363 [3] 刘泽金, 周朴, 王小林, 等. 金宝搏188软件怎么用 相干合成的历史、现状与发展趋势(邀请论文)[J]. 中国金宝搏188软件怎么用 ,2010,37(9):2221-2234. doi: 10.3788/CJL20103709.2221LIU Z J, ZHOU P, WANG X L, et al. The history, development and tend of coherent combining of laser beams[J]. Chinese Journal of Lasers, 2010, 37(9): 2221-2234. (in Chinese) doi: 10.3788/CJL20103709.2221 [4] MADASAMY P, LOFTUS T, THOMAS A, et al. Comparison of spectral beam combining approaches for high power fiber laser systems[J]. Proceedings of SPIE, 2008, 6952: 695207. doi: 10.1117/12.783147 [5] SPRANGLE P, TING A, PENANO J, et al. Incoherent combining and atmospheric propagation of high-power fiber lasers for directed-energy applications[J]. IEEE Journal of Quantum Electronics, 2009, 45(2): 138-148. doi: 10.1109/JQE.2008.2002501 [6] 王富国, 杨洪波, 赵文兴, 等. 1.2 m SiC主镜轻量化设计与分析[J]. 光学 精密工程,2009,17(1):85-91.WANG F G, YANG H B, ZHAO W X, et al. Lightweight design and analysis of a 1.2 m SiC primary mirror[J]. Optics and Precision Engineering, 2009, 17(1): 85-91. (in Chinese) [7] 王富国, 杨洪波, 杨飞, 等. 大口径主镜轴向支撑点位置优化分析[J]. 红外与金宝搏188软件怎么用 工程,2007,36(6):877-880. doi: 10.3969/j.issn.1007-2276.2007.06.028WANG F G, YANG H B, YANG F, et al. Optimization and analysis for the axis support points position of the large aperture mirrors[J]. Infrared and Laser Engineering, 2007, 36(6): 877-880. (in Chinese) doi: 10.3969/j.issn.1007-2276.2007.06.028 [8] 宫辉, 连华东. 大口径SiC反射镜背部筋板布局设计研究[J]. 航天返回与遥感,2009,30(2):56-61, 69. doi: 10.3969/j.issn.1009-8518.2009.02.009GONG H, LIAN H D. Study on design of back ribs for large-aperture SiC mirror[J]. Spacecraft Recovery &Remote Sensing, 2009, 30(2): 56-61, 69. (in Chinese) doi: 10.3969/j.issn.1009-8518.2009.02.009 [9] 包奇红, 沙巍, 陈长征, 等. 中心支撑φ610 mm圆形主镜的超轻量化设计[J]. 光子学报,2016,45(9):0912007. doi: 10.3788/gzxb20164509.0912007BAO Q H, SHA W, CHEN CH ZH, et al. Ultra-lightweight design of φ610 mm circular primary mirror supported in centre[J]. Acta Photonica Sinica, 2016, 45(9): 0912007. (in Chinese) doi: 10.3788/gzxb20164509.0912007 [10] 王克军. 天基大口径反射镜轻量化设计及复合支撑技术研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2016.WANG K J. Research on the lightweight design and compound support of the large-aperture mirror for space-based telescope[D]. Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, 2016. (in Chinese) [11] 汤伟, 郭劲, 邵俊峰, 等. 金宝搏188软件怎么用 重频对脉冲非稳腔TEA CO2金宝搏188软件怎么用 远场传输特性的影响分析[J]. 红外与金宝搏188软件怎么用 工程,2013,42(9):2380-2385. doi: 10.3969/j.issn.1007-2276.2013.09.015TANG W, GUO J, SHAO J F, et al. Analysis of far-field characteristics with repetition frequency of TEA CO2 laser[J]. Infrared and Laser Engineering, 2013, 42(9): 2380-2385. (in Chinese) doi: 10.3969/j.issn.1007-2276.2013.09.015 [12] 伞晓刚, 孙宁, 卓仁善, 等. 大口径光电经纬仪主反射镜支撑结构设计[J]. 光学 精密工程,2013,21(12):3111-3117. doi: 10.3788/OPE.20132112.3111SAN X G, SUN N, ZHUO R SH, et al. Design of supporting structure for primary mirror of large aperture theodolite[J]. Optics and Precision Engineering, 2013, 21(12): 3111-3117. (in Chinese) doi: 10.3788/OPE.20132112.3111 -

下载:

下载: