Differential chromatic confocal roughness evaluation system and experimental research

-

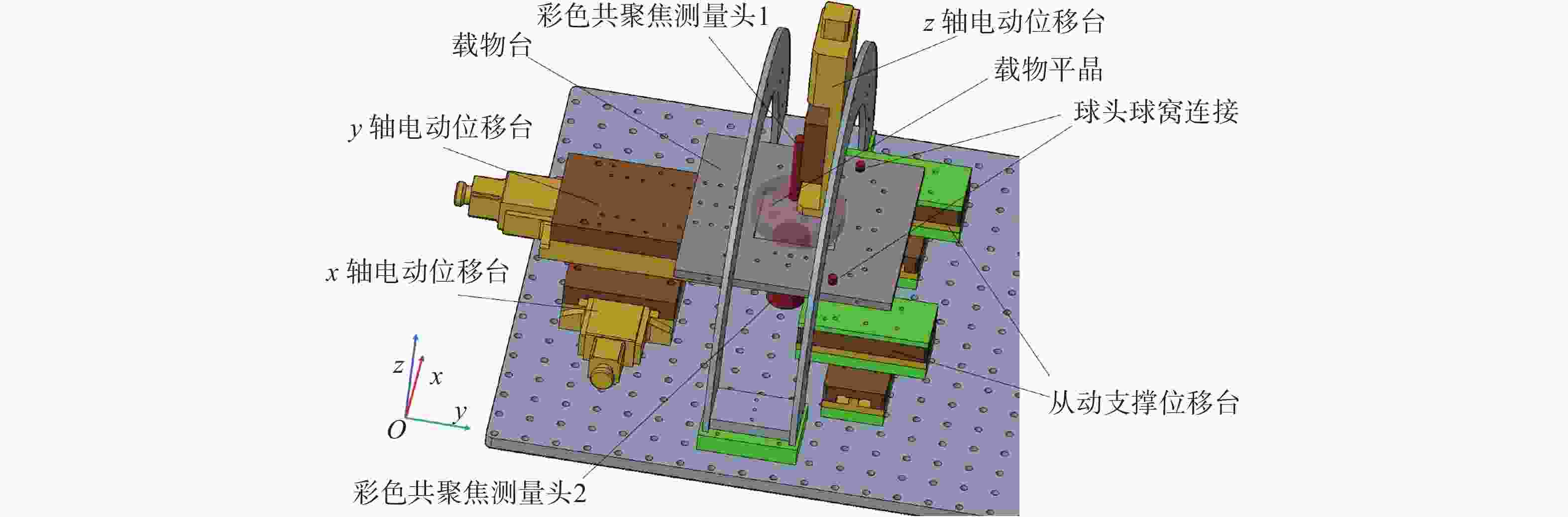

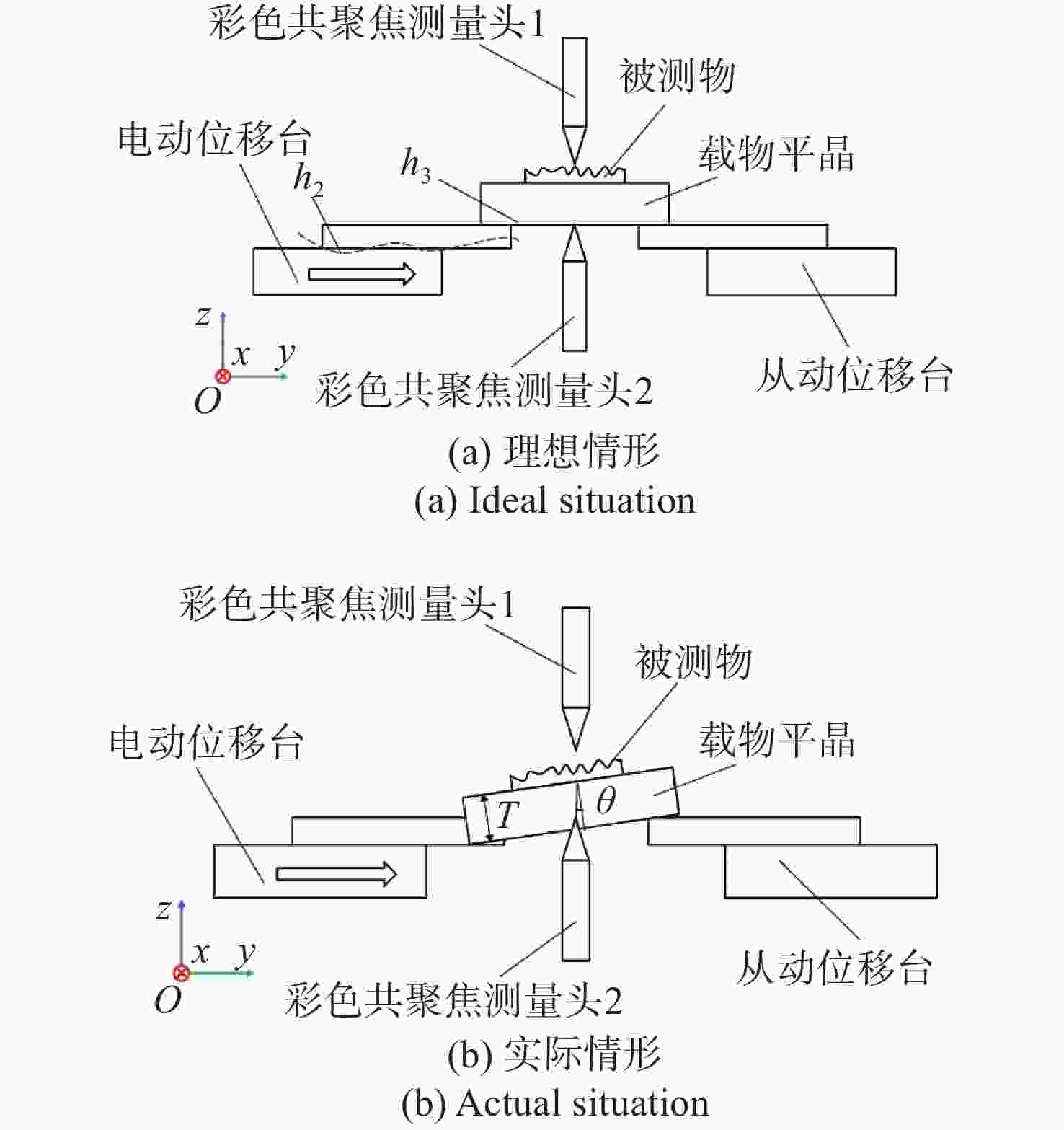

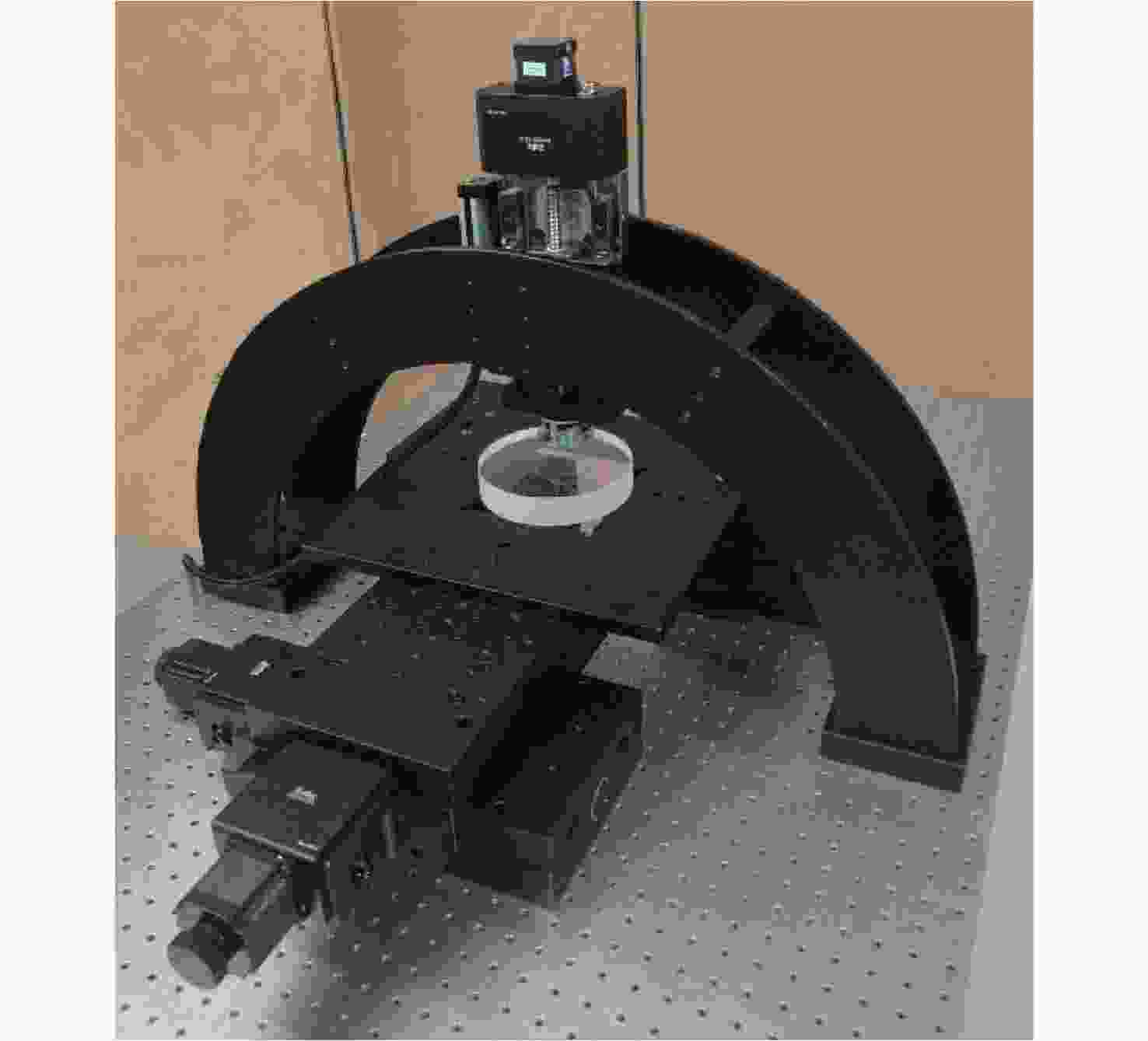

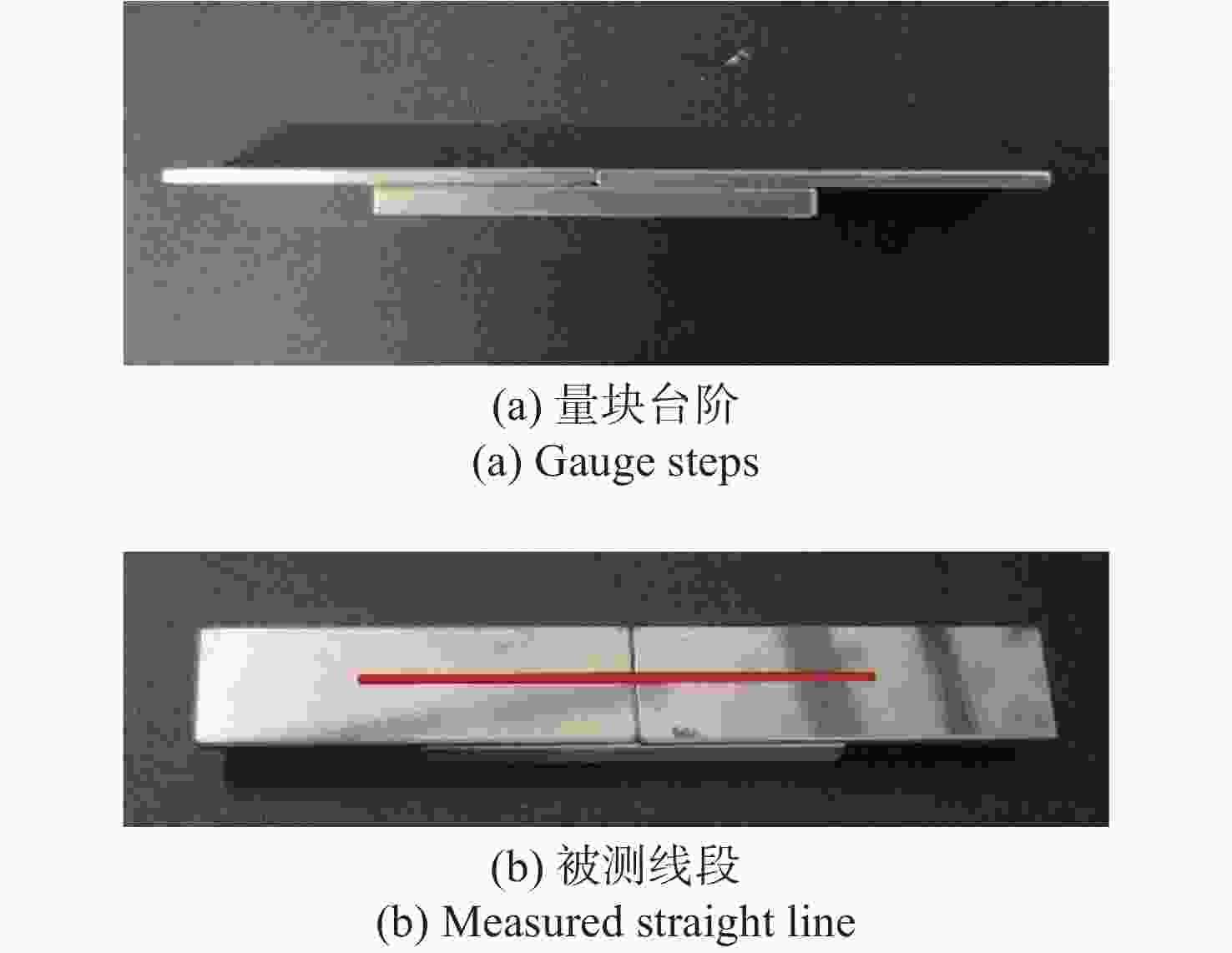

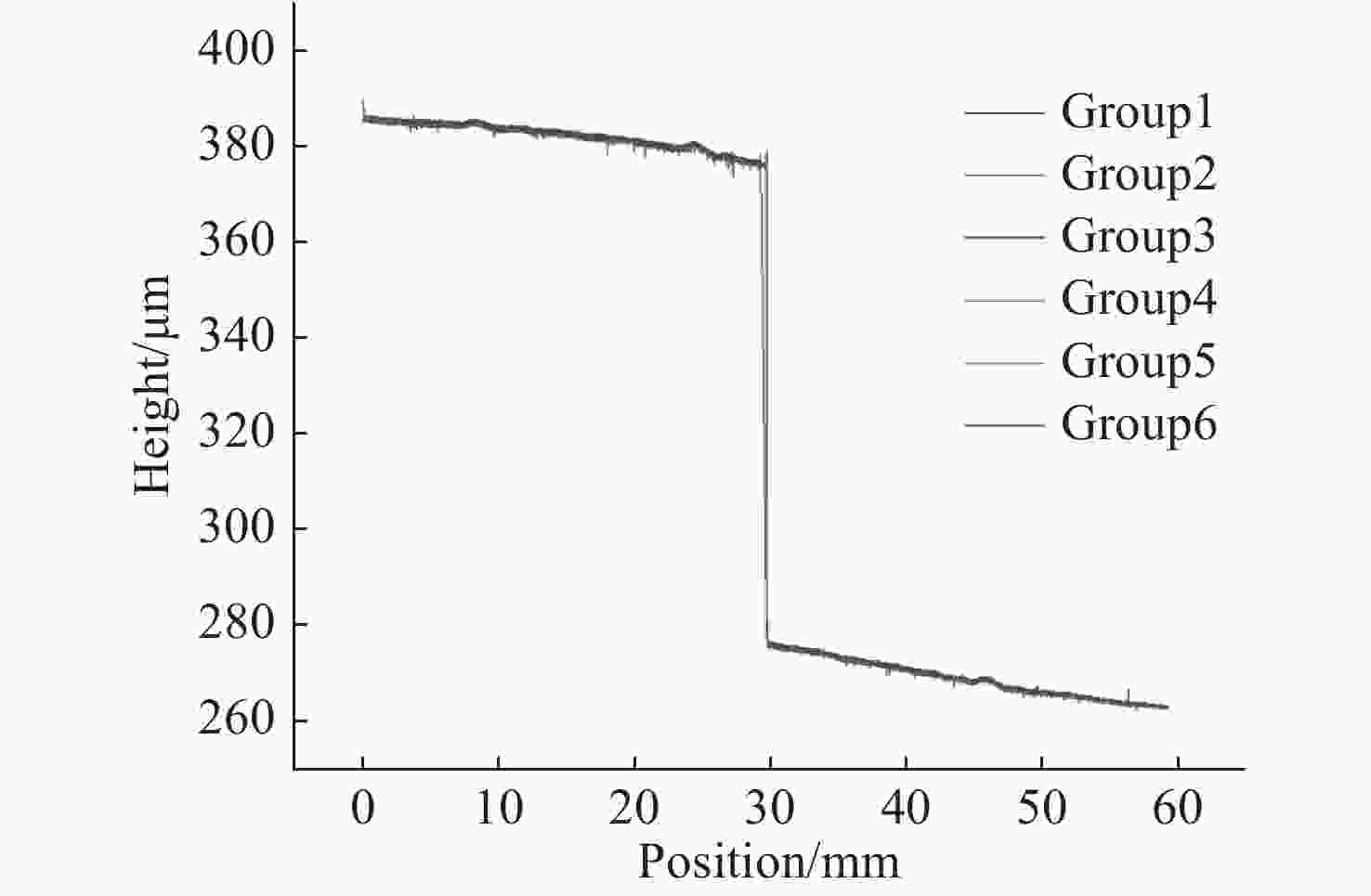

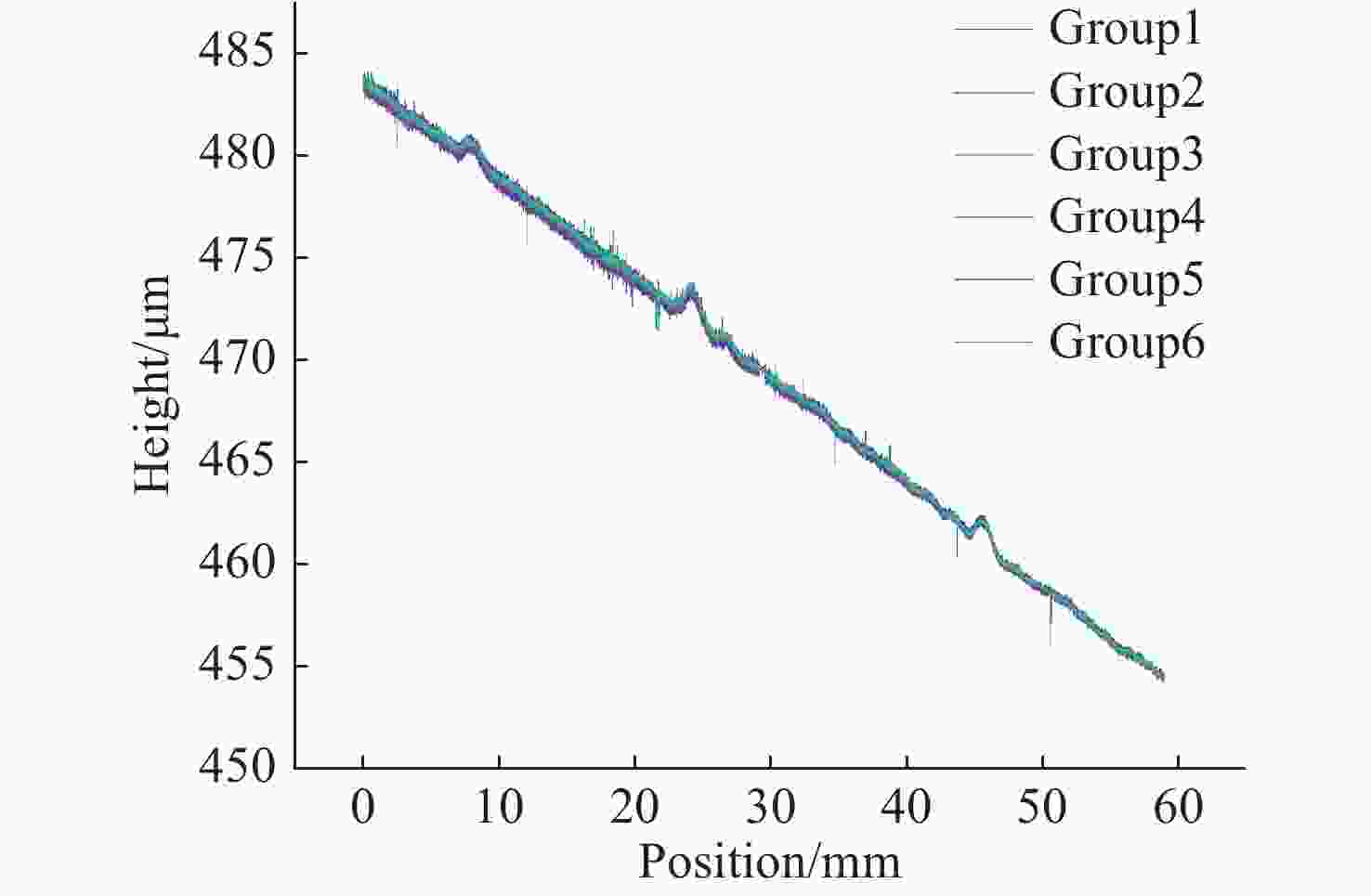

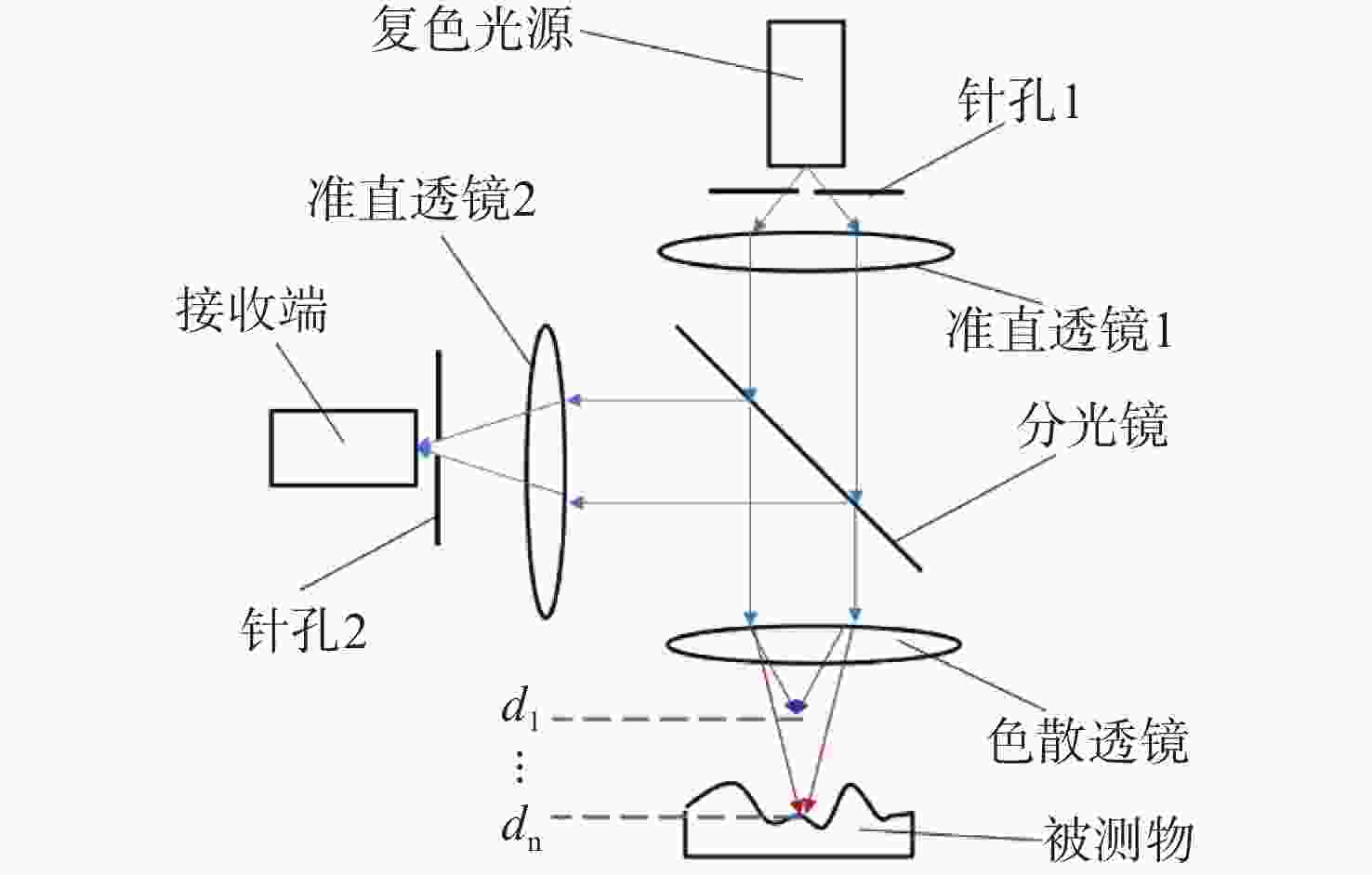

摘要: 为了满足大范围表面粗糙度测量评定的需求,本文介绍了一种基于彩色共聚焦传感器的差动式非接触测量评定系统和方法。在所提出的系统中,两个彩色共聚焦传感器和一个光学平晶构成差动式测量系统,并通过球头球窝连接方式与机械运动平台耦合。使用这种差动式结构可以补偿机械运动平台的直线度误差,并可以有效地提高测量评定精度。在此基础上,本文建立了表面粗糙度测量、误差补偿和测量性能评估的方法。为了验证所提出系统的性能,对标准高度台阶量块和粗糙度量块进行了测量评定实验。台阶高度的测量实验结果表明,在60 mm的行程范围内,所提出系统6次重复测量的标准偏差s为0.16 μm,相对标准偏差RSD为0.054%,机械运动平台的直线度误差得到了有效补偿;在测量粗糙度量块时,粗糙度参数Ra和Rq的测量误差分别为0.032 μm和0.073 μm。所提出系统的粗糙度测量评定能力满足大多数工程应用的需求。Abstract: In order to meet the demand of large-area surface roughness measurement, a non-contact differential measurement system based on chromatic confocal sensors is presented in this paper. In the proposed system, two chromatic sensors and an optical flat, forming a differential measurement structure, are coupled with the motion system with a ball-to-socket connection. Using this differential configuration, the straightness error of the motion system is compensated and the measurement accuracy can be effectively improved. Based on this system, the methodology of surface roughness measurement, error compensation and measurement performance evaluation is established. In order to verify the measurement performance of the proposed system, standard step heights and roughness comparators are measured. For the step height measurement, the experimental results show that in the travel range of 60 mm, the standard deviation of the proposed system in six repeated measurements is 0.16 μm and the relative standard deviation RSD is 0.054%. From the results, it can be concluded that the straightness error of the motion system has been effectively overcome. When measuring the roughness comparators, the measurement errors of Ra and Rq are 0.032 μm and 0.073 μm, respectively. Therefore, the roughness measurement capability of the proposed system meets the requirements of most engineering applications.

-

表 1 直线导轨选型表

Table 1. Linear guide types and corresponding parameters

名 称 型 号 行 程/mm 闭环分辨率/μm x、y轴位移台 卓立Uksa100 100 0.1 z轴位移台 卓立Ksa050 50 1 从动位移台 THK VRU6210 110 — 表 2 测头技术参数

Table 2. Probe's technical parameters

名称 量程/μm 轴向分辨率/nm 彩色共聚焦测量头1 1000 5 彩色共聚焦测量头2 600 3 表 3 粗糙度Ra对比数据(μm)

Table 3. Comparative data of Ra (μm)

Mahr XR20 本文评定装置 样品 Ra 标准偏差s Ra 标准偏差s 6.3 5.810 0.000577 5.842 0.003971 3.2 2.728 0.001000 2.736 0.002338 1.6 1.471 0.000577 1.493 0.002317 0.8 0.622 0.000577 0.589 0.002251 表 4 Rq对比数据(μm)

Table 4. Comparative data of Rq (μm)

Mahr XR20 本文评定装置 样品 Rq 标准偏差s Rq 标准偏差s 6.3 6.728 0.000577 6.753 0.006623 3.2 3.234 0.001000 3.238 0.003559 1.6 1.737 0.000577 1.746 0.001049 0.8 0.787 0.000577 0.714 0.000753 -

PARK J B, YANG S M, KO Y. Evaluation of the surface characteristics of various implant abutment materials using confocal microscopy and white light interferometry[J]. Implant Dentistry, 2015, 24(6): 650-656. 何宝凤, 丁思源, 魏翠娥, 等. 三维表面粗糙度测量方法综述[J]. 光学 精密工程,2019,27(1):78-93. doi: 10.3788/OPE.20192701.0078HE B F, DING S Y, WEI C E, et al. Review of measurement methods for a real surface roughness[J]. Optics and Precision Engineering, 2019, 27(1): 78-93. (in Chinese) doi: 10.3788/OPE.20192701.0078 ZHENG Y, ZHANG X, WANG SH D, et al. Similarity evaluation of topography measurement results by different optical metrology technologies for additive manufactured parts[J]. Optics and Lasers in Engineering, 2020, 126: 105920. doi: 10.1016/j.optlaseng.2019.105920 何宝凤, 魏翠娥, 刘柄显, 等. 三维表面粗糙度的表征和应用[J]. 光学 精密工程,2018,26(8):1994-2011. doi: 10.3788/OPE.20182608.1994HE B F, WEI C E, LIU B X, et al. Three-dimensional surface roughness characterization and application[J]. Optics and Precision Engineering, 2018, 26(8): 1994-2011. (in Chinese) doi: 10.3788/OPE.20182608.1994 张金峰, 封超, 马芸慧, 等. 微铣金属表面微沟槽结构的粗糙度及形貌分析[J]. 光学 精密工程,2018,26(12):2998-3011. doi: 10.3788/OPE.20182612.2998ZHANG J F, FENG CH, MA Y H, et al. Analysis of roughness and morphology of metal surface grooves by micro milling[J]. Optics and Precision Engineering, 2018, 26(12): 2998-3011. (in Chinese) doi: 10.3788/OPE.20182612.2998 LIN T, HU Y, KONG L T, et al. Effect of surface roughness on plasticity of Zr52.5Cu17.9Ni14.6Al10Ti5 bulk metallic glass[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1407-1411. doi: 10.1016/S1003-6326(11)61333-2 KONG F X, SUN T, GENG Y Q, et al. Measurement method of Wolter-I type mandrel based on a contact-type profilometer[J]. Proceedings of the Institution of Mechanical Engineers,Part B:Journal of Engineering Manufacture, 2019, 233(11): 2173-2182. doi: 10.1177/0954405419830010 周秋凤. GB/T 1031—2009《产品几何技术规范(GPS)表面结构 轮廓法 表面粗糙度参数及其数值》介绍[J]. 机械工业标准化与质量,2010(3):30-32, 37. doi: 10.3969/j.issn.1007-6905.2010.03.007ZHOU Q F. Introduction to GB/T 1031-2009 Geometrical Product Specifications (GPS). Surface texture: profile method, Surface roughness parameters and their values[J]. Machinery Industry Standardization &Quality, 2010(3): 30-32, 37. (in Chinese) doi: 10.3969/j.issn.1007-6905.2010.03.007 FU SH W, CHENG F, TJAHJOWIDODO T, et al. A non-contact measuring system for in-situ surface characterization based on laser confocal microscopy[J]. Sensors, 2018, 18(8): 2657. doi: 10.3390/s18082657 XUE B, GENG Y Q, YAN Y D, et al. Effects of AFM tip wear on evaluating the surface quality machined by ultra-precision machining process[J]. The International Journal of Advanced Manufacturing Technology, 2019, 105(11): 4663-4675. doi: 10.1007/s00170-019-03958-x 徐伟. 基于光纤传感器的深孔内表面粗糙度测量方法研究[D]. 镇江: 江苏大学, 2018.XU W. Research on detection method of inner surface roughness for deep hole based on fiber optical sensor [D]. Zhenjiang: Jiangsu University, 2018. (in Chinese) 任志英, 高诚辉, 申丁, 等. 双树复小波稳健滤波在工程表面粗糙度评定中的应用[J]. 光学 精密工程,2014,22(7):1820-1827. doi: 10.3788/OPE.20142207.1820REN ZH Y, GAO CH H, SHEN D, et al. Application of DT-CWT robust filtering to evaluation of engineering surface roughness[J]. Optics and Precision Engineering, 2014, 22(7): 1820-1827. (in Chinese) doi: 10.3788/OPE.20142207.1820 齐兴华. 三维表面粗糙度测量与评定[D]. 哈尔滨: 哈尔滨理工大学, 2017.QI X H. Measurement and evaluation of three dimensional surface roughness [D]. Harbin: Harbin University of Science and Technology, 2017. (in Chinese) 张恒, 孙建春, 向芬, 等. 隧道施工通风壁面粗糙度评定方法及其工程应用[J]. 安全与环境学报,2019,19(1):217-225.ZHANG H, SUN J CH, XIANG F, et al. Assessment method to deal with the wall face roughness in the tunnel construction and its application[J]. Journal of Safety and Environment, 2019, 19(1): 217-225. (in Chinese) 刘颖, 郎治国, 唐文彦. 表面粗糙度光切显微镜测量系统的研制[J]. 红外与金宝搏188软件怎么用 工程,2012,41(3):775-779. doi: 10.3969/j.issn.1007-2276.2012.03.042LIU Y, LANG ZH G, TANG W Y. Development of measurement system about light-section microscope for surface roughness[J]. Infrared and Laser Engineering, 2012, 41(3): 775-779. (in Chinese) doi: 10.3969/j.issn.1007-2276.2012.03.042 瞿雪元, 顾廷权, 方百友. 带钢表面粗糙度在线检测技术最新进展[J]. 电子测量与仪器学报,2017,31(4):493-500.QU X Y, GU T Q, FANG B Y. Review of surface roughness online measurement techniques of steel strip[J]. Journal of Electronic Measurement and Instrumentation, 2017, 31(4): 493-500. (in Chinese) 蔡雯, 陈培锋, 王英, 等.基于金宝搏188软件怎么用 散射的表面粗糙度测量系统研究 [J/OL]. 金宝搏188软件怎么用 技术: 1-10[2020-01-09]. http://kns.cnki.net/kcms/detail/51.1125.TN.20191206.1456.002.html.CAI W, CHEN P F, WANG Y, et al.. Research of surface roughness measurement system based on laser scattering[J/OL]. Laser Technology: 1-10[2020-01-09]. http://kns.cnki.net/kcms/detail/51.1125.TN.20191206.1456.002.html. (in Chinese) 易怀安. 基于色彩信息的机器视觉粗糙度检测方法研究[D]. 长沙: 湖南大学, 2017.YI H A. Research on the machine vision methods for roughness detection based on color information [D]. Changsha: Hunan University, 2017. (in Chinese) 李业学, 张学林, 徐福卫, 等. 工件粗糙度在线检测的试验研究[J]. 实验力学,2018,33(5):807-815. doi: 10.7520/1001-4888-17-065LI Y X, ZHANG X L, XU F W, et al. Experimental study on online detection of workpiece roughness[J]. Journal of Experimental Mechanics, 2018, 33(5): 807-815. (in Chinese) doi: 10.7520/1001-4888-17-065 韩晓芹, 宋永锋, 刘雨, 等. 基于超声无损评价的表面粗糙度测量方法[J]. 中国机械工程,2019,30(8):883-889. doi: 10.3969/j.issn.1004-132X.2019.08.001HAN X Q, SONG Y F, LIU Y, et al. A surface roughness measurement method based on ultrasonic nondestructive evaluations[J]. China Mechanical Engineering, 2019, 30(8): 883-889. (in Chinese) doi: 10.3969/j.issn.1004-132X.2019.08.001 朱南南, 张骏. 表面粗糙度金宝搏188软件怎么用 散射检测的多波长光纤传感器[J]. 红外与金宝搏188软件怎么用 工程,2016,45(5):522003. doi: 10.3788/irla201645.0522003ZHU N N, ZHANG J. Multi-wavelength fiber sensor for measuring surface roughness based on laser scattering[J]. Infrared and Laser Engineering, 2016, 45(5): 522003. (in Chinese) doi: 10.3788/irla201645.0522003 臧俊涛. 基于机器视觉与机器学习的磨削齿面粗糙度测量研究[D]. 长沙: 湖南大学, 2018.ZANG J T. Research on grinding gear surface roughness measurement methods based on machine vision and machine learning [D]. Changsha: Hunan University, 2018. (in Chinese) 余卿, 余晓芬, 崔长彩, 等. 并行共焦测量中的并行光源技术综述[J]. 中国光学,2013,6(5):652-659.YU Q, YU X F, CUI CH C, et al. Survey of parallel light source technology in parallel confocal measurement[J]. Chinese Optics, 2013, 6(5): 652-659. (in Chinese) BAI J, LI X H, WANG X H, et al. Chromatic confocal displacement sensor with optimized dispersion probe and modified centroid peak extraction algorithm[J]. Sensors, 2019, 19(16): 3592. doi: 10.3390/s19163592 ZINT M, STOCK K, CLAUS D, et al. Development and verification of a snapshot dental intraoral three-dimensional scanner based on chromatic confocal imaging[J]. Journal of Medical Imaging, 2019, 6(3): 033502. 朱鸿. 光谱共焦位移传感器信号处理与校准研究[D]. 武汉: 华中科技大学, 2019.ZHU H. Research on signal processing and calibration of spectral confocal displacement sensor [D]. Wuhan: Huazhong University of Science and Technology, 2019. (in Chinese) 西北工业大学机械原理及机械零件教研室. 机械原理[M]. 北京: 高等教育出版社, 1987.Teaching and Research Section of Mechanical Principle and Mechanical Parts of Northwest Polytechnic University. Theory of Machines and Mechanisms[M]. Beijing: Higher Education Press, 1987. (in Chinese) -

下载:

下载: