-

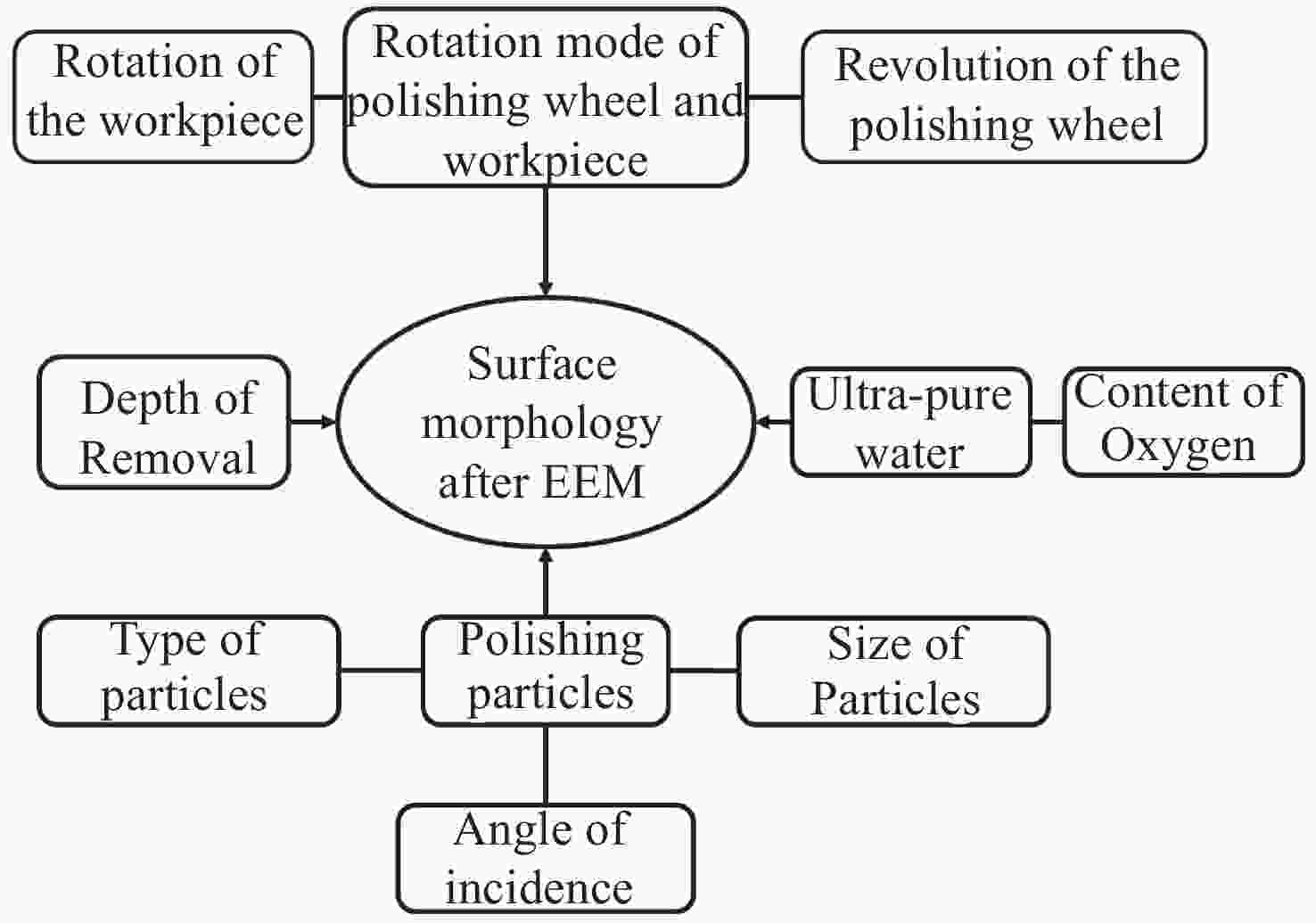

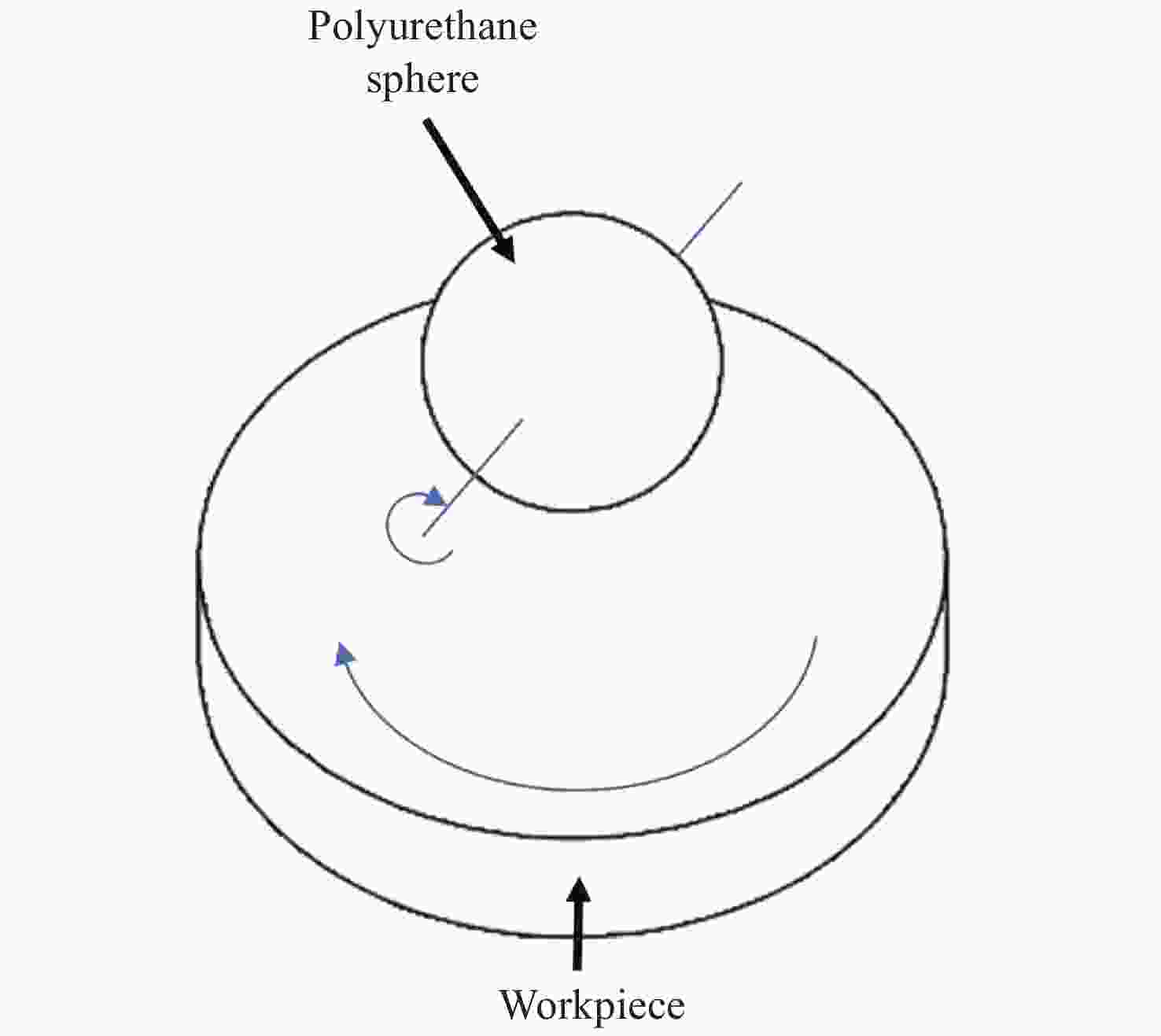

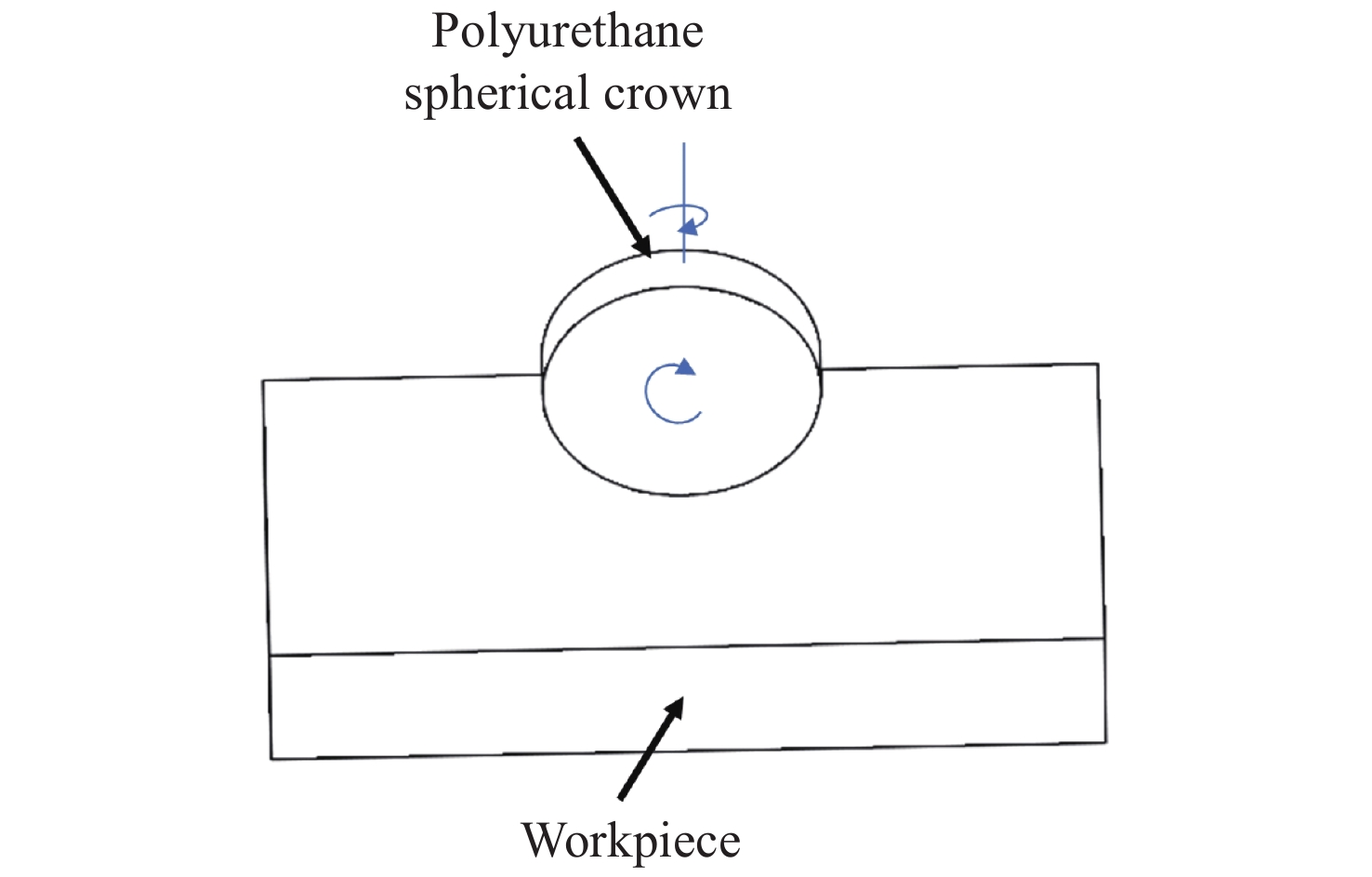

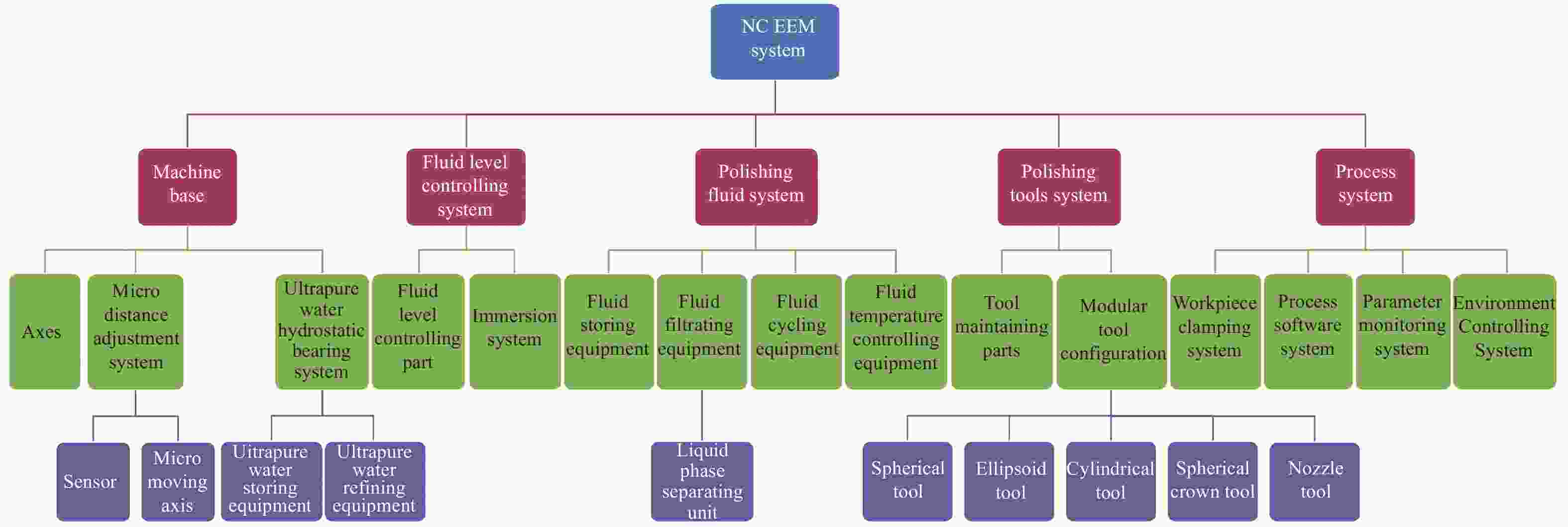

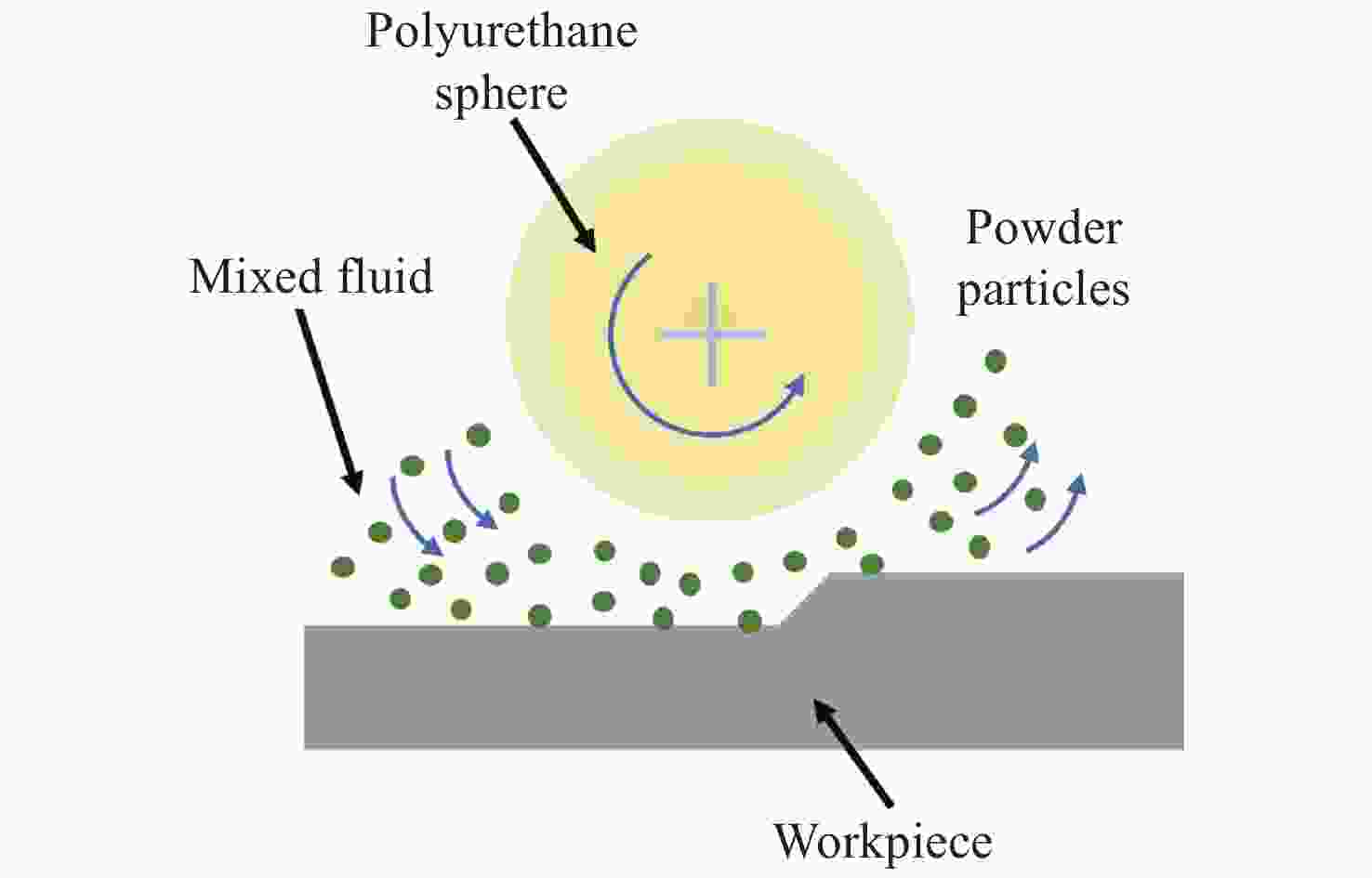

摘要: 深紫外光刻、极紫外光刻和先进光源等现代光学工程需求牵引先进光学制造技术持续发展,要求超光滑光学元件表面粗糙度达到原子级水平以及表面全频段面形误差达到RMS(Root Mean Square)亚纳米量级甚至几十皮米,推动超光滑光学元件制造要求不断逼近物理极限。目前,对于如何实现上述超高精度要求的超光滑加工技术及装备仍然存在技术挑战。尤其对如何实现柱面,椭球面,超环面等复杂曲面的原子量级超光滑加工仍是国内外前沿研究方向。弹性发射加工技术是一种去除函数稳定,超低亚表面缺陷,面向原子级的超光滑加工方法,可以作为加工上述精度要求光学元件的手段。本文总结了弹性发射加工技术的国内外研究现状及最新进展,归纳了弹性发射加工技术的原理,包含流体特性、抛光颗粒运动特性和化学特性,弹性发射加工装备,影响弹性发射加工技术表面粗糙度提升和材料去除效率的因素,分析了弹性发射加工技术面临的问题,展望了未来的发展方向,期望为弹性发射加工技术进一步发展和应用提供一定的参考。Abstract: The requirements of modern optical engineering in fields such as deep ultraviolet lithography, extreme ultraviolet lithography and advanced light sources drive the continuous development of advanced optical manufacturing technology. Modern optical engineering requires the surface roughness of ultra-smooth optical components to reach the atomic level and the surface shape profile error in the full spatial frequency to reach RMS(Root Mean Square) sub-nanometer or even a few dozen picometers. This drives the manufacturing requirements of ultra-smooth optical components to approach the processing limits. At present, there are still technical challenges to achieve the ultra-smooth polishing technology and equipment required for the above ultra-high precision needs. Atomic level ultra-smooth polishing of complex surfaces such as cylinders, ellipsoids and toroids is still a primary direction of research at both domestically and abroad. Elastic emission machining is an atomic-level ultra-smooth processing method with stable removal functionality and ultra-low subsurface defect creation, which can be used for manufacturing optical components with the above-mentioned accuracy requirements. We summarize the research progress of elastic emission machining and equipment at both domestically and abroad, the principles of elastic emission machining which contains fluid characteristics, the movement characteristics of polishing particles and chemical characteristics, the equipment of elastic emission machining, and the factors affecting the improvement of surface roughness and material removal rate of elastic emission machining. Then we analyze the problems faced by elastic emission machining and equipment and look forward to their prospects. It is expected that this paper will provide a reference for the further development and application of elastic emission machining.

-

表 1 弹性发射加工技术流体驱动方式[9, 19, 26, 43, 44]

Table 1. Fluid-driven methods of elastic emission machining[9, 19, 26, 43, 44]

Category Polishing tool form Advantage ■ and Disadvantage ● Polishing ball type EEM Spherical

■ It can polish curved optical components.

● It has a low material removal rate and has

side leakage.Ellipsoid

■ Enlarge the interaction area and material

removal rate.

■ The curvature of the tool will change, and

the curved surface can be processed, which is

more suitable for concave components.Polishing wheel type EEM Cylindrical

■ Expand the processing area, improve the

material removal rate and there is no side

leakage.

■ The removal function is linear, and only

planes and cylinders with a single curvature

can be processed.Spherical crown

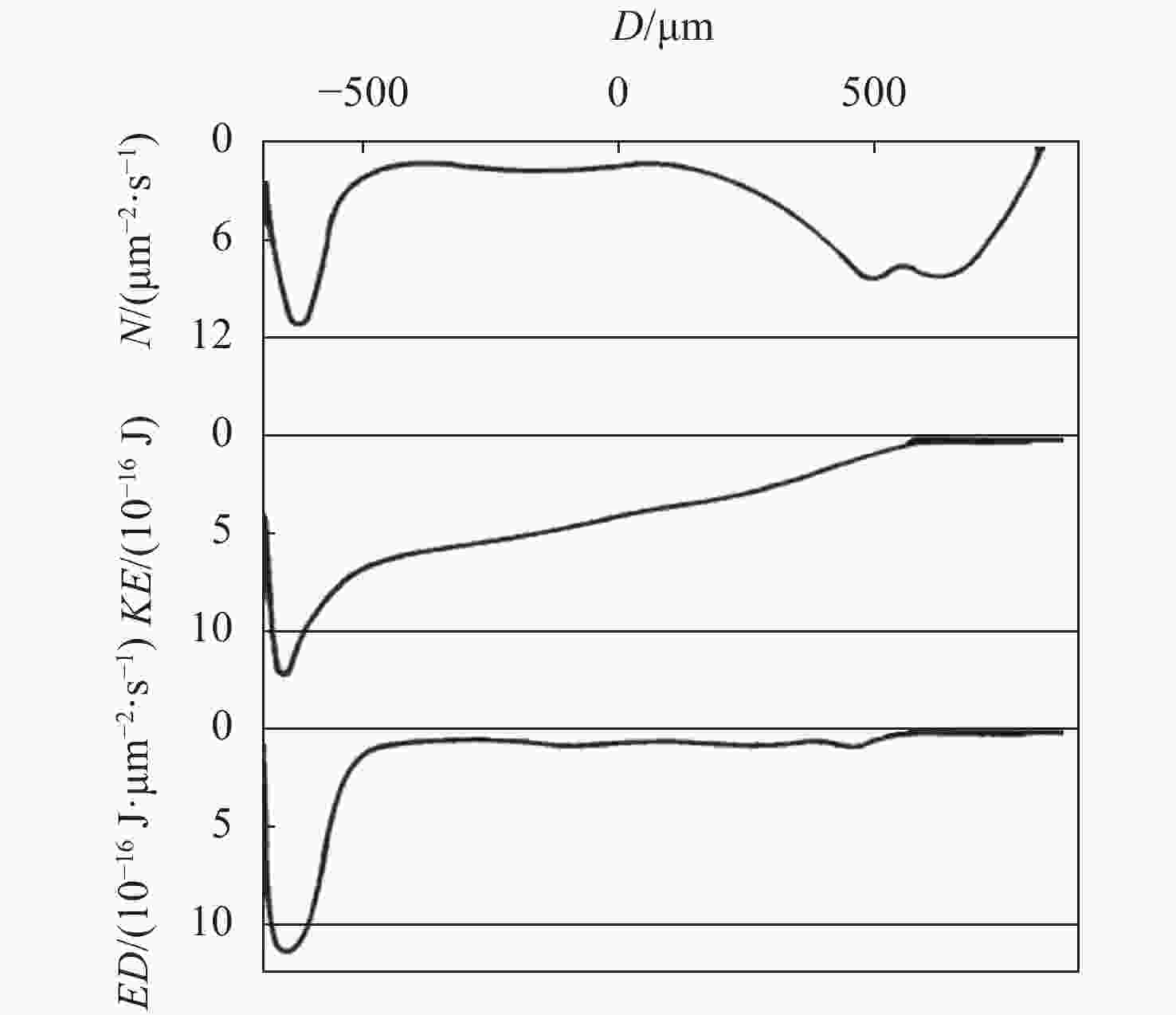

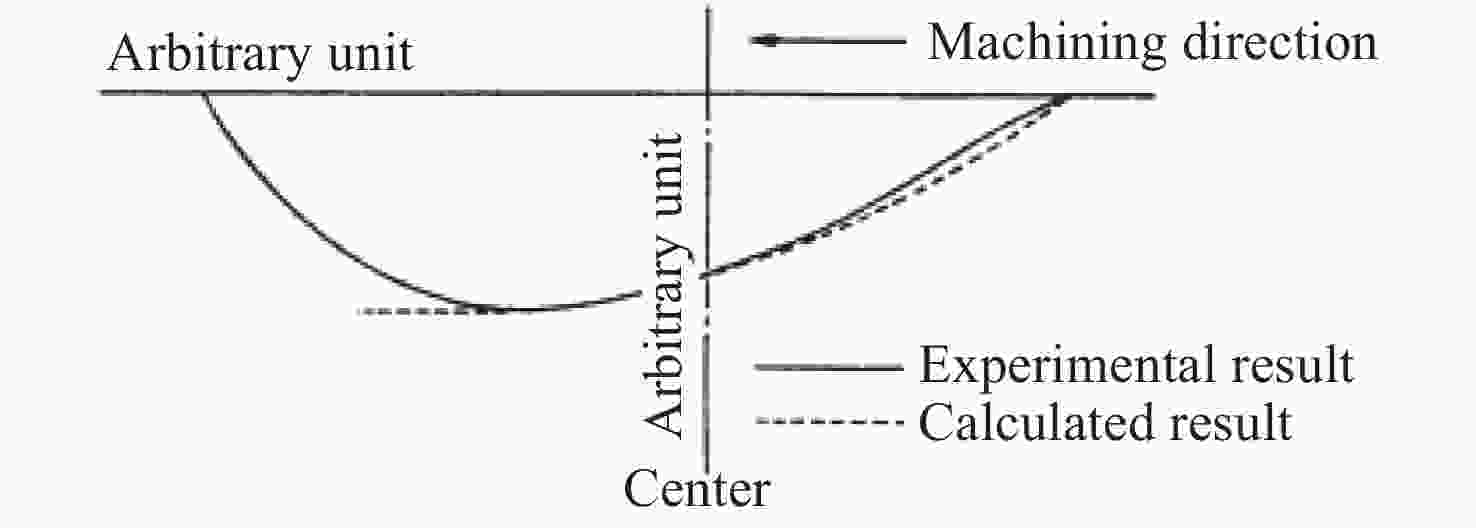

■ It can polish curved optical components. Nozzle type EEM

■ It is easy to control and can accurately

polish optical components.

■ It is not constrained by the shape of optical

components.表 2 用不同形状的抛光颗粒加工光学表面前后的表面质量和材料去除效率[51]

Table 2. Surface quality and material removal rate of preprocessed and EEM processed surfaces for polishing particles with different shapes[51]

Preprocessed surface Processed using spherical particles Processed using

agglomerated

particlesP-V/nm 2.286 0.9360 1.412 RMS/nm 0.1940 0.0980 0.1410 Material removal rate/(nm·h−1) 1.000 120.00 表 3 影响剪切力的因素

Table 3. Factors affecting shear stress in EEM

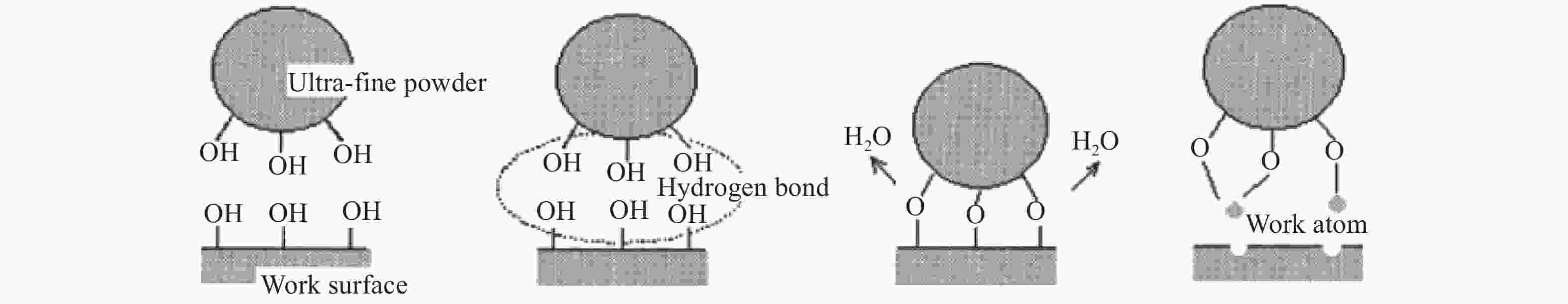

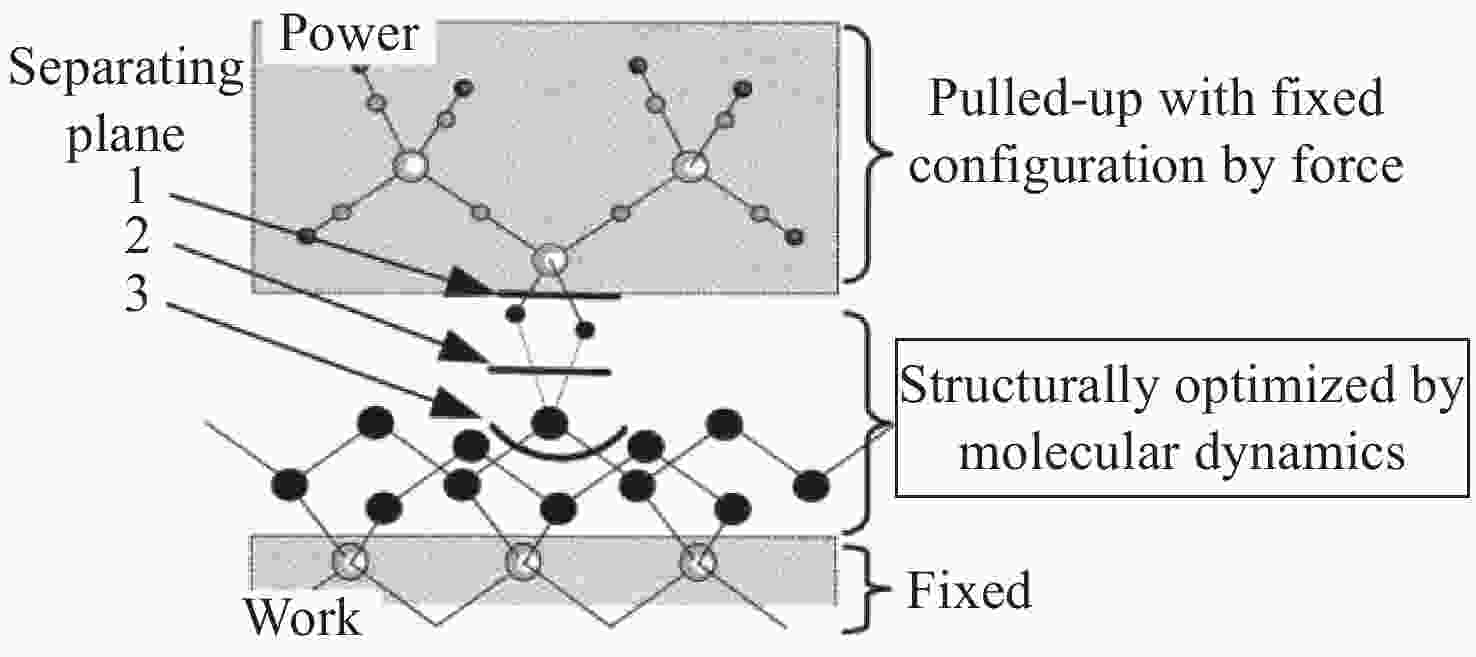

Parameter types Factors Processing parameters Liquid film thickness. Applied load Polishing fluid parameters The size, surface morphology, lattice orientation

and incident angle of polishing particles.

Ultrapure water temperature.

The viscosity and concentration of polishing fluidPolishing tool parameters The shape, curvature, speed, surface roughness,

material elastic modulus of polishing toolOptical component parameters The material, lattice orientation,

surface roughness, ripple, geometric

parameters of optical components表 4 参数与剪切力在不同状态下的关系

Table 4. The relationship of parameters with shear stress in different conditions

IR IE VE Polishing tool rotation Negative Positive Positive Polishing fluid viscosity Negative Positive Positive Pressure-viscosity coefficient — — Negative Elastic modulus — Positive Positive Polishing tool radius Positive Positive Positive Load Positive Positive Positive 表 5 弹性发射加工技术在表面粗糙度和材料去除效率方面的研究现状[10, 12, 14, 24, 45, 51, 55]

Table 5. Research status of surface roughness and material removal rates in EEM[10, 12, 14, 24, 45, 51, 55]

Material Surface roughness(RMS) Material removal rate Si 0.080 nm 120 nm/h Zerodur 0.085 nm 1.25×10−3 mm3/h 4H-SiC 0.089 nm − SiC 0.640 nm − Fused silica 0.085 nm − -

[1] YUMOTO H, KOYAMA T, MATSUYAMA S, et al. Ultra-high-precision surface processing techniques for nanofocusing ellipsoidal mirrors in hard X-ray region[J]. Proceedings of SPIE, 2014, 9206: 920605. [2] TAKEI Y, KUME T, MOTOYAMA H, et al. Development of a numerically controlled elastic emission machining system for fabricating mandrels of ellipsoidal focusing mirrors used in soft x-ray microscopy[J]. Proceedings of SPIE, 2013, 8848: 88480C. [3] YUMOTO H, KOYAMA T, MATSUYAMA S, et al. Ellipsoidal mirror for two-dimensional 100-nm focusing in hard X-ray region[J]. Scientific Reports, 2017, 7: 16408. doi: 10.1038/s41598-017-16468-1 [4] 赵晨行, 卢启鹏, 宋源, 等. 自由电子金宝搏188软件怎么用 光束线反射镜无应力夹持设计与分析[J]. 中国光学,2020,13(4):787-794. doi: 10.37188/CO.2019-0131ZHAO CH X, LU Q P, SONG Y, et al. Design and analysis of stress-free clamping of mirrors used in free-electron laser beamlines[J]. Chinese Optics, 2020, 13(4): 787-794. (in Chinese) doi: 10.37188/CO.2019-0131 [5] SIEWERT F, BUCHHEIM J, GWALT G, et al. On the characterization of a 1 m long, ultra-precise KB-focusing mirror pair for European XFEL by means of slope measuring deflectometry[J]. Review of Scientific Instruments, 2019, 90(2): 021713. doi: 10.1063/1.5065473 [6] WEISER M. Ion beam figuring for lithography optics[J]. Nuclear Instruments and Methods in Physics Research Section B:Beam Interactions with Materials and Atoms, 2009, 267(8-9): 1390-1393. doi: 10.1016/j.nimb.2009.01.051 [7] LIN B, JIANG X M, CAO ZH CH, et al. Novel disc hydrodynamic polishing process and tool for high-efficiency polishing of ultra-smooth surfaces[J]. Micromachines, 2018, 9(7): 333. doi: 10.3390/mi9070333 [8] 袁巨龙, 吴喆, 吕冰海, 等. 非球面超精密抛光技术研究现状[J]. 机械工程学报,2012,48(23):167-177. doi: 10.3901/JME.2012.23.167YUAN J L, WU ZH, LÜ B H, et al. Review on ultra-precision polishing technology of aspheric surface[J]. Journal of Mechanical Engineering, 2012, 48(23): 167-177. (in Chinese) doi: 10.3901/JME.2012.23.167 [9] YAMAMURA K, MIMURA H, YAMAUCHI K, et al. Aspheric surface fabrication in nm-level accuracy by numerically controlled plasma chemical vaporization machining (CVM) and elastic emission machining (EEM)[J]. Proceedings of SPIE, 2002, 4782: 265-270. doi: 10.1117/12.453749 [10] KANAOKA M, TAKINO H, NOMURA K, et al. Removal properties of low-thermal-expansion materials with rotating-sphere elastic emission machining[J]. Science and Technology of Advanced Materials, 2007, 8(3): 170-172. doi: 10.1016/j.stam.2006.12.003 [11] 彭文强. 基于材料弹性域去除的超光滑表面加工关键技术研究[D]. 长沙: 国防科学技术大学, 2014.PENG W Q. Study on the key technology of ultrasmooth surface fabrication based on the material removal in elastic mode[D]. Changsha: Graduate School of National University of Defense Technology, 2014. (in Chinese) [12] KUBOTA A, SHINBAYASHI Y, MIMURA H, et al. Investigation of the surface removal process of silicon carbide in elastic emission machining[J]. Journal of Electronic Materials, 2007, 36(1): 92-97. doi: 10.1007/s11664-006-0006-3 [13] PENG W Q, LI SH Y, GUAN CH L, et al. Improvement of magnetorheological finishing surface quality by nanoparticle jet polishing[J]. Optical Engineering, 2013, 52(4): 043401. doi: 10.1117/1.OE.52.4.043401 [14] KUBOTA A, MIMURA H, INAGAKI K, et al. Preparation of ultrasmooth and defect-free 4H-SiC(0001) surfaces by elastic emission machining[J]. Journal of Electronic Materials, 2005, 34(4): 439-443. doi: 10.1007/s11664-005-0124-3 [15] HIRATA T, TAKEI Y, MIMURA H. Machining property in smoothing of steeply curved surfaces by elastic emission machining[J]. Procedia CIRP, 2014, 13: 198-202. doi: 10.1016/j.procir.2014.04.034 [16] SIDPARA A. Elastic Emission Machining[M]. Boca Raton: CRC Press, 2017. [17] MORI Y, TSUWA H, SUGIYAMA K. EEM (Elastic Emission Machining) (1st Report): concept of EEM and its feasibility[J]. Journal of the Japan Society of Precision Engineering, 1977, 43(509): 542-548. doi: 10.2493/jjspe1933.43.542 [18] TURNER T. Superpolished optics enable high-sensitivity laser applications[EB/OL]. https://www.photonics.com/Articles/Superpolished_Optics_Enable_High-Sensitivity/a52258. [19] KIM J D. Motion analysis of powder particles in EEM using cylindrical polyurethane wheel[J]. International Journal of Machine Tools and Manufacture, 2002, 42(1): 21-28. doi: 10.1016/S0890-6955(01)00095-5 [20] MORI Y, IKAWA N, OKUDA T, et al. Numerically controlled elastic emission machining: motion analysis of fluid and distribution of film thickness[J]. Journal of the Japan Society of Precision Engineering, 1983, 49(11): 1540-1548. doi: 10.2493/jjspe1933.49.1540 [21] ZHANG L H, WANG J L, ZHANG J. Super-smooth surface fabrication technique and experimental research[J]. Applied Optics, 2012, 51(27): 6612-6617. doi: 10.1364/AO.51.006612 [22] CAO ZH CH, LIN B, JIANG X M, et al. Flow field analysis of the thin fluid film in disc hydrodynamic polishing[J]. Procedia CIRP, 2018, 77: 363-366. doi: 10.1016/j.procir.2018.09.036 [23] KANAOKA M, TAKINO H, NOMURA K, et al.. Factors affecting changes in removal rate of elastic emission machining[C]. Proceedings of ASPE 2008 Annual Meeting and the Twelfth ICPE, 2008: 615-618. [24] KANAOKA M, LIU CH L, NOMURA K, et al. Processing efficiency of elastic emission machining for low-thermal-expansion material[J]. Surface and Interface Analysis, 2008, 40(6-7): 1002-1006. doi: 10.1002/sia.2818 [25] 徐兴芹. 弹性发射加工中磨粒群运动特性的研究[D]. 大连: 大连理工大学, 2013.XU X Q. Study of behaviour of particle group movement in elastic emission machining[D]. Dalian: Dalian University of Technology, 2013. (in Chinese) [26] MORI Y. Elastic emission machining and its surface[J]. Journal of the Japan Society of Precision Engineering, 1980, 46(6): 659-666. doi: 10.2493/jjspe1933.46.659 [27] MORI Y, OKUDA T, SUGIYAMA K, et al. Numerically controlled elastic emission machining: consideration of machining property by motion analysis of powder particle in fluid[J]. Journal of the Japan Society of Precision Engineering, 1985, 51(5): 1033-1039. doi: 10.2493/jjspe1933.51.1033 [28] KANAOKA M, NOMURA K, YAMAUCHI K, et al.. Efficiency-enhanced elastic emission machining on the basis of processing mechanism[C]. Proceedings of the 12th Euspen International Conference, 2012: 193-196. [29] KANAOKA M, NOMURA K, YAMAUCHI K, et al. Powder particle behavior at the processing point of elastic emission machining[J]. The Proceedings of the Manufacturing &Machine Tool Conference, 2012, 9: 143-144. [30] YAMAUCHI K, HIROSE K, GOTO H, et al. First-principles simulations of removal process in EEM (Elastic Emission Machining)[J]. Computational Materials Science, 1999, 14(1-4): 232-235. doi: 10.1016/S0927-0256(98)00112-8 [31] MORI Y, YAMAUCHI K, ENDO K. Elastic emission machining[J]. Precision Engineering, 1987, 9(3): 123-128. doi: 10.1016/0141-6359(87)90029-8 [32] INAGAKI K, YAMAUCHI K, MIMURA H, et al. First-principles evaluations of machinability dependency on powder material in elastic emission machining[J]. Materials Transactions, 2001, 42(11): 2290-2294. doi: 10.2320/matertrans.42.2290 [33] PENG W Q, GUAN CH L, LI SH Y. Efficient fabrication of ultrasmooth and defect-free quartz glass surface by hydrodynamic effect polishing combined with ion beam figuring[J]. Optics Express, 2014, 22(11): 13951-13961. doi: 10.1364/OE.22.013951 [34] 宋孝宗. 纳米颗粒胶体射流抛光机理及试验研究[D]. 哈尔滨: 哈尔滨工业大学, 2010.SONG X Z. Research on mechanism and experiments of nanoparticle colloid jet polishing[D]. Harbin: Harbin Institute of Technology, 2010. (in Chinese) [35] PENG W Q, GUAN CH L, LI SH Y. Defect-free surface of quartz glass polished in elastic mode by chemical impact reaction[J]. Journal of Central South University, 2014, 21(12): 4438-4444. doi: 10.1007/s11771-014-2446-x [36] 何宗海, 赵永彬. JP-25型重力式平衡机原理——兼讨论十字弹簧特性[J]. 试验技术与试验机,1984(4):10-17, 72.HE Z H, ZHAO Y B. The principle of JP-25 gravity balancing machine-discussing the characteristics of cross spring[J]. Engineering and Testing, 1984(4): 10-17, 72. (in Chinese) [37] MORI Y. Polishing device: Japan, 62-088565A[P]. 1987-04-23. [38] MORI Y. Polishing device: Japan, 62-199353A[P]. 1987-09-03. [39] 张富. 弹性约束游离磨料超光滑表面加工技术的研究[D]. 长春: 吉林大学, 2007.ZHANG F. Study on elastically constrained and dissociated abrasive polishing for ultra-smooth surfaces[D]. Changchun: Jilin University, 2007. (in Chinese) [40] 朱崇涛. 液流悬浮超光滑加工机理及抛光动压力的研究[D]. 长春: 吉林大学, 2007.ZHU CH T. Study on principle of hydrodynamic suspension ultra-smooth machining and dynamic pressure of polishing[D]. Changchun: Jilin University, 2007. (in Chinese) [41] 张恩忠. 液流悬浮超光滑加工不同材料的对比研究[D]. 长春: 吉林大学, 2006.ZHANG E ZH. Contrastive investigation into hydrodynamic suspension ultra-smooth processing different material[D]. Changchun: Jilin University, 2006. (in Chinese) [42] WANG J L, WANG SH ZH, LIU J, et al.. Polishing device for fork type support: CN, WO2013091208A1[P]. 2013-06-27. [43] 王君, 金春水, 王丽萍, 等. 一种用于弹性发射加工的工具轮: 中国, 105563271A[P]. 2016-05-11.WANG J, JIN CH SH, WANG L P, et al.. Tool wheels used for elastic emission machining: CN, 105563271A[P]. 2016-05-11. (in Chinese) [44] 李庆宇. 基于流体动力润滑效应的双转弹性发射加工技术研究[D]. 长沙: 国防科学技术大学, 2015.LI Q Y. Study on the technology of elastic emission machining with dual-rotor based on hydrodynamic lubrication[D]. Changsha: Graduate School of National University of Defense Technology, 2015. (in Chinese) [45] MORI Y, YAMAUCHI Y, YAMAMURA K, et al. Development of plasma chemical vaporization machining and elastic emission machining systems for coherent X-ray optics[J]. Proceedings of SPIE, 2001, 4501: 30-42. doi: 10.1117/12.448496 [46] YAMAUCHI K, KATAOKA T, ENDO K, et al. A study on EEM (Elastic Emission Machining): influences of dissolved oxygen to Si wafer surface[J]. Journal of the Japan Society for Precision Engineering, 1998, 64(6): 907-912. doi: 10.2493/jjspe.64.907 [47] MORI Y, IKAWA N, SUGIYAMA K, et al. Elastic Emission Machining (2nd Report): stress field and feasibility of introduction and activation of lattice defect[J]. Journal of the Japan Society of Precision Engineering, 1985, 51(6): 1187-1194. doi: 10.2493/jjspe1933.51.1187 [48] KUBOTA A, MIMURA H, INAGAKI K, et al. Morphological stability of Si(001) surface immersed in fluid mixture of ultrapure water and silica powder particles in elastic emission machining[J]. Japanese Journal of Applied Physics, 2005, 44(8R): 5893-5897. [49] 宋辞, 李圣怡, 李庆宇, 等. 一种用于获取超光滑表面的双转轮式弹性发射加工装置: 中国, 105345640A[P]. 2016-02-24.SONG C, LI SH Y, LI Q Y, et al.. Double-turning-wheel type elastic emission machining device used for obtaining super-smooth surface: CN, 105345640A[P]. 2016-02-24. (in Chinese) [50] SU Y T, WANG S Y, CHAO P Y, et al. Investigation of elastic emission machining process: lubrication effects[J]. Precision Engineering, 1995, 17(3): 164-172. doi: 10.1016/0141-6359(94)00014-Q [51] KUBOTA A, MIMURA H, INAGAKI K, et al. Effect of particle morphology on removal rate and surface topography in elastic emission machining[J]. Journal of the Electrochemical Society, 2006, 153(9): G874. doi: 10.1149/1.2220068 [52] PENG W Q, GUAN CH L, LI SH Y. Ultrasmooth surface polishing based on the hydrodynamic effect[J]. Applied Optics, 2013, 52(25): 6411-6416. doi: 10.1364/AO.52.006411 [53] 彭文强, 关朝亮, 胡旭东, 等. 流体动压超光滑加工关键工艺参数优化[J]. 国防科技大学学报,2017,39(4):179-184. doi: 10.11887/j.cn.201704028PENG W Q, GUAN CH L, HU X D, et al. Key process parameters optimization of hydrodynamic effect polishing[J]. Journal of National University of Defense Technology, 2017, 39(4): 179-184. (in Chinese) doi: 10.11887/j.cn.201704028 [54] TAKEI Y, MIMURA H. Effect of focusing flow on stationary spot machining properties in elastic emission machining[J]. Nanoscale Research Letters, 2013, 8(1): 237. doi: 10.1186/1556-276X-8-237 [55] TAKINO H, KANAOKA M, NOMURA K. Ultraprecision machining of optical surfaces[C]. Proceedings of International Symposium on Ultraprecision Engineering and Nanotechnology, 2011: 5-10. [56] OHASHI H, TSUMURA T, OKADA H, et al. Microstitching interferometer and relative angle determinable stitching interferometer for half-meter-long X-ray mirror[J]. Proceedings of SPIE, 2007, 6704: 670405. doi: 10.1117/12.733476 [57] LAUNDY D, SAWHNEY K, NISTEA I, et al. Development of a multi-lane X-ray mirror providing variable beam sizes[J]. Review of Scientific Instruments, 2016, 87(5): 051802. doi: 10.1063/1.4950732 [58] DA SILVA J C, PACUREANU A, YANG Y, et al. Efficient concentration of high-energy X-rays for diffraction-limited imaging resolution[J]. Optica, 2017, 4(5): 492-495. doi: 10.1364/OPTICA.4.000492 [59] WEN M W, KOZHEVNIKOV I V, SIEWERT F, et al. Effect of the surface roughness on X-ray absorption by mirrors operating at extremely small grazing angles[J]. Optics Express, 2018, 26(16): 21003-21018. doi: 10.1364/OE.26.021003 [60] YAMAUCHI K, YAMAMURA K, MIMURA H, et al. Two-dimensional submicron focusing of hard X-rays by two elliptical mirrors fabricated by plasma chemical vaporization machining and elastic emission machining[J]. Japanese Journal of Applied Physics, 2003, 42(11R): 7129-7134. [61] MORI Y, YAMAUCHI K, YAMAMURA K, et al. Fabrication technology of hard X-ray aspherical mirror optics and application to nanospectroscopy[J]. Proceedings of SPIE, 2004, 5193: 11-17. doi: 10.1117/12.515127 [62] YAMAUCHI K, YAMAMURA K, MIMURA H, et al. Fabrication technology of ultraprecise mirror optics to realize hard X-ray nanobeam[J]. Proceedings of SPIE, 2004, 5533: 116-123. doi: 10.1117/12.567501 [63] MIMURA H, YUMOTO H, MATSUYAMA S, et al. Surface figuring and measurement methods with spatial resolution close to 0.1 mm for X-ray mirror fabrication[J]. Proceedings of SPIE, 2005, 5921: 59210M. doi: 10.1117/12.623103 [64] YUMOTO H, MIMURA H, KOYAMA T, et al. Focusing of X-ray free-electron laser pulses with reflective optics[J]. Nature Photonics, 2013, 7(1): 43-47. doi: 10.1038/nphoton.2012.306 [65] TAKEI Y, MIMURA H. Development of surface profiler for master mandrel of X-ray ellipsoidal mirror[J]. Proceedings of SPIE, 2016, 9962: 99620C. [66] MATSUYAMA S, YASUDA S, YAMADA J, et al. 50-nm-resolution full-field X-ray microscope without chromatic aberration using total-reflection imaging mirrors[J]. Scientific Reports, 2017, 7: 46358. doi: 10.1038/srep46358 [67] 张帅, 侯溪. K-B镜面形高精度检测技术研究进展[J]. 中国光学,2020,13(4):660-675. doi: 10.37188/CO.2019-0231ZHANG SH, HOU X. Research progress of high-precision surface metrology of a K-B mirror[J]. Chinese Optics, 2020, 13(4): 660-675. (in Chinese) doi: 10.37188/CO.2019-0231 [68] KANAOKA M, HIGUCHI T, YAMAMOTO T, et al.. Ultra-precision surface polishing technologies achieved in the field of ultraviolet optics[C]. Optical Design and Fabrication 2017, Optical Society of America, 2017. [69] MURAKAMI K, OSHINO T, KONDO H, et al. Development progress of optics for extreme ultraviolet lithography at Nikon[J]. Journal of Micro/Nanolithography,MEMS,and MOEMS, 2009, 8(4): 041507. doi: 10.1117/1.3238522 -

下载:

下载: