High precision structural light scanning viewpoint planning for aircraft blade morphology

-

摘要:

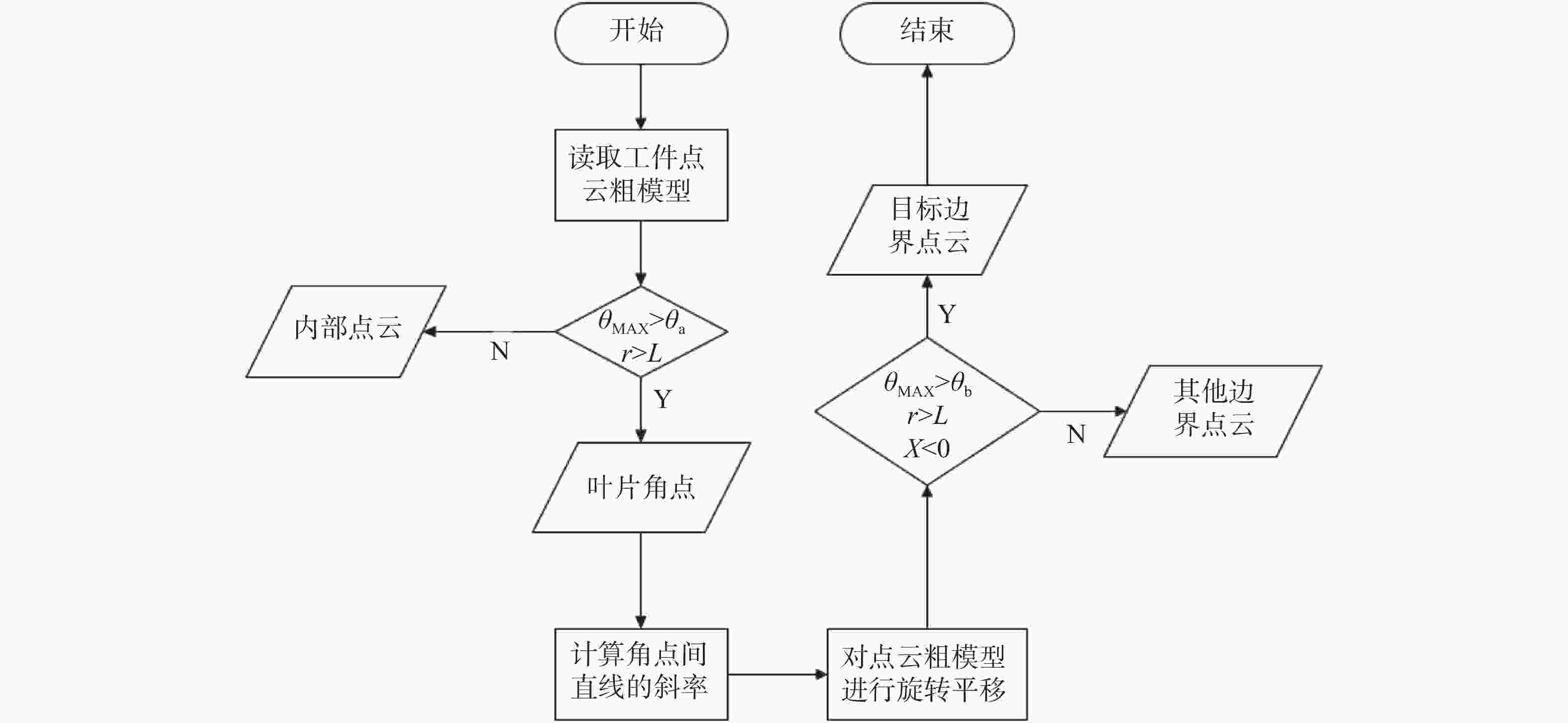

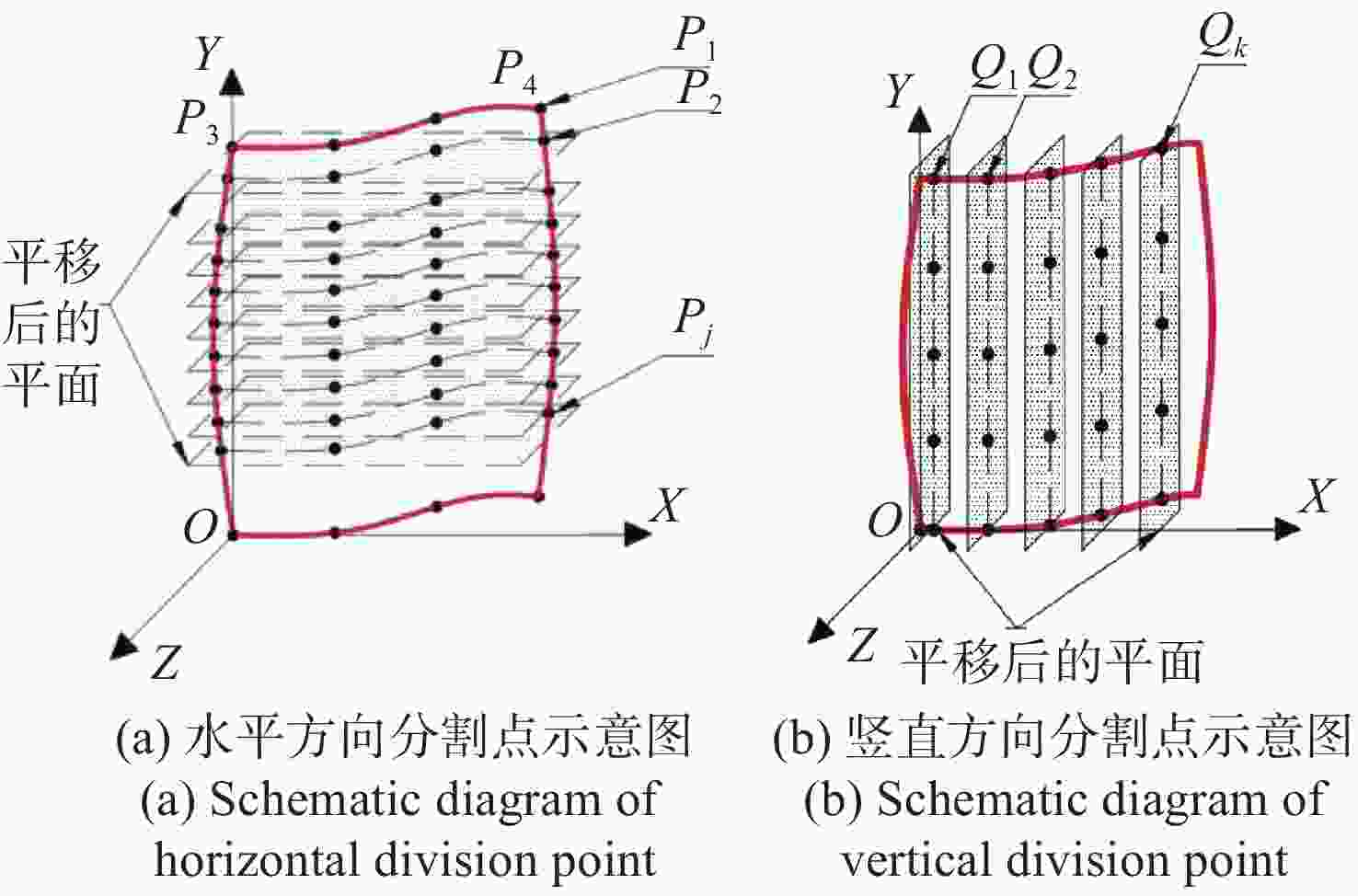

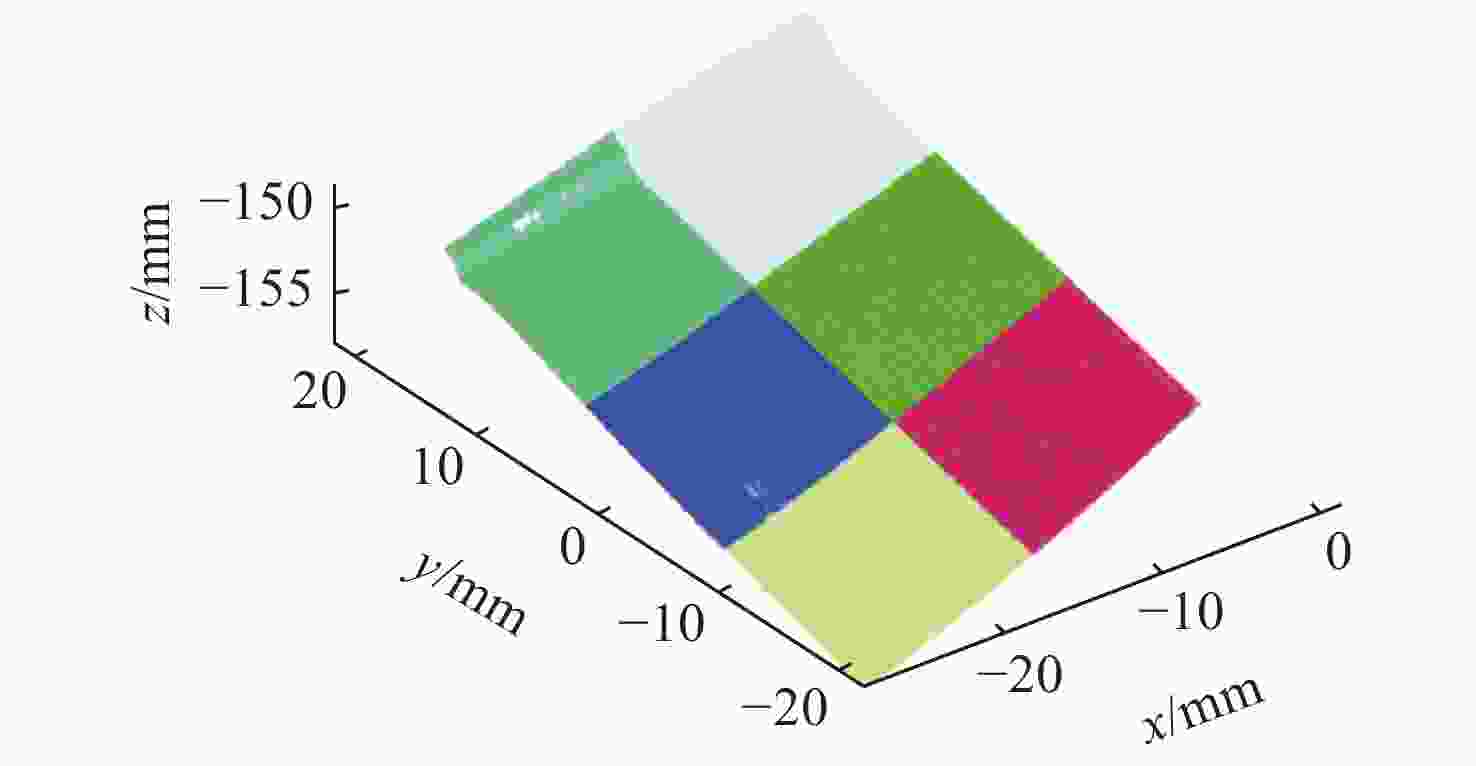

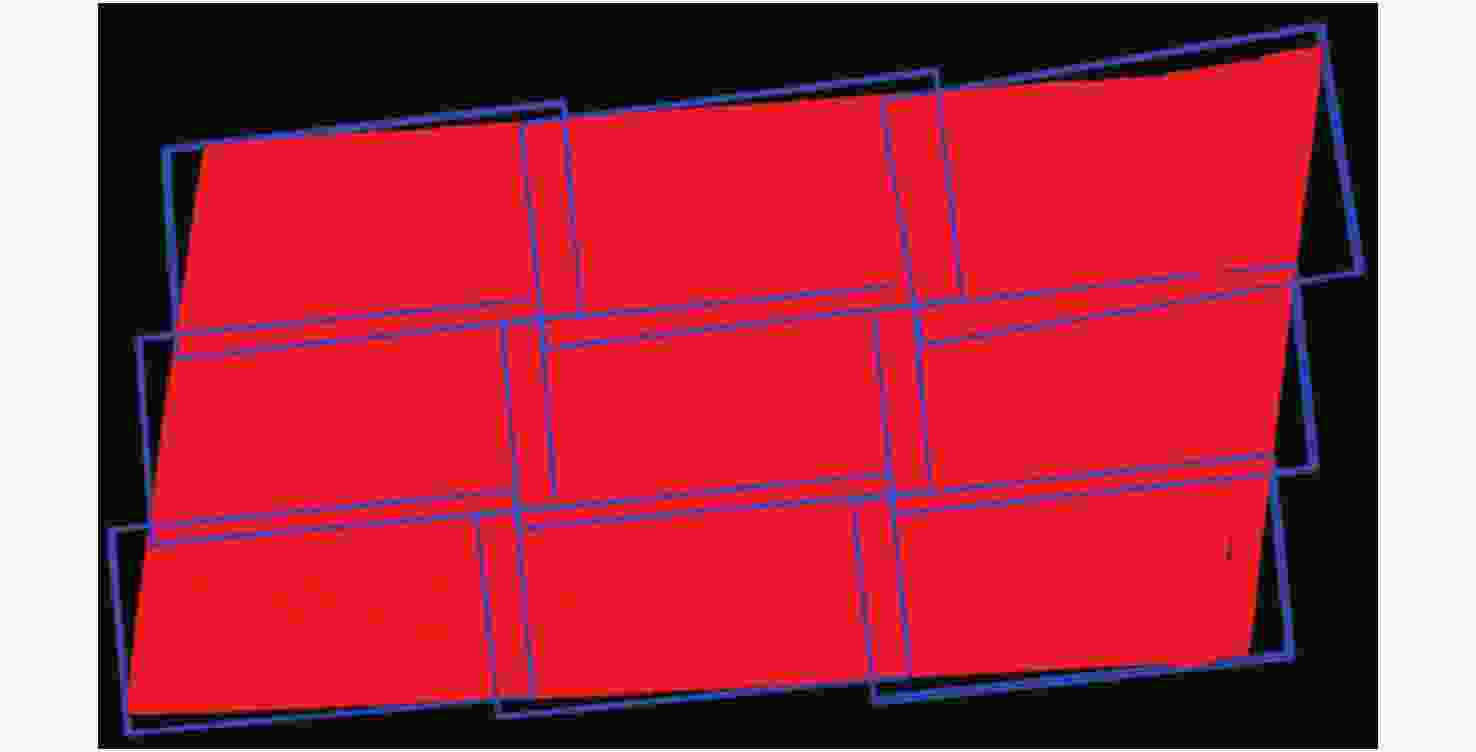

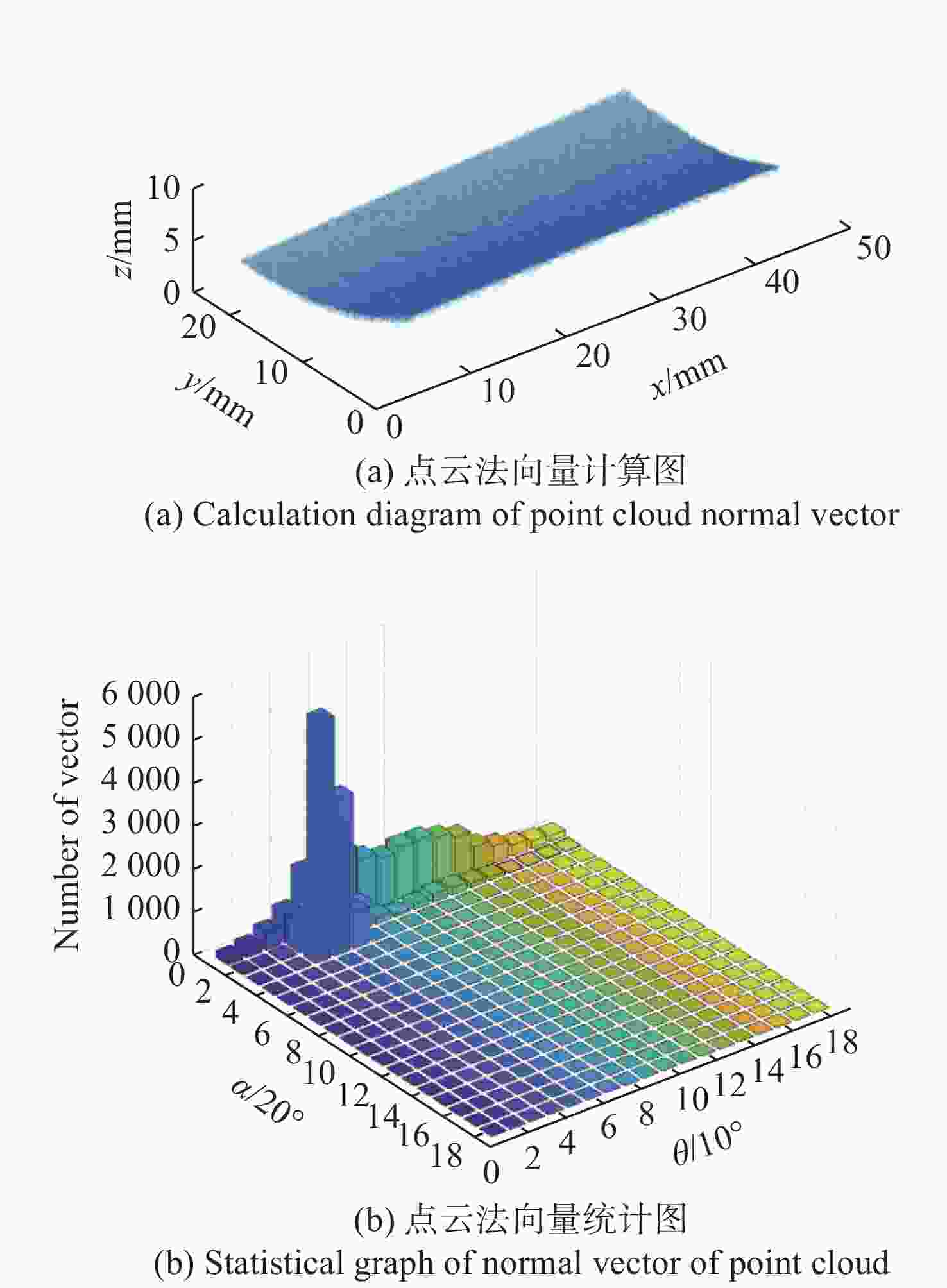

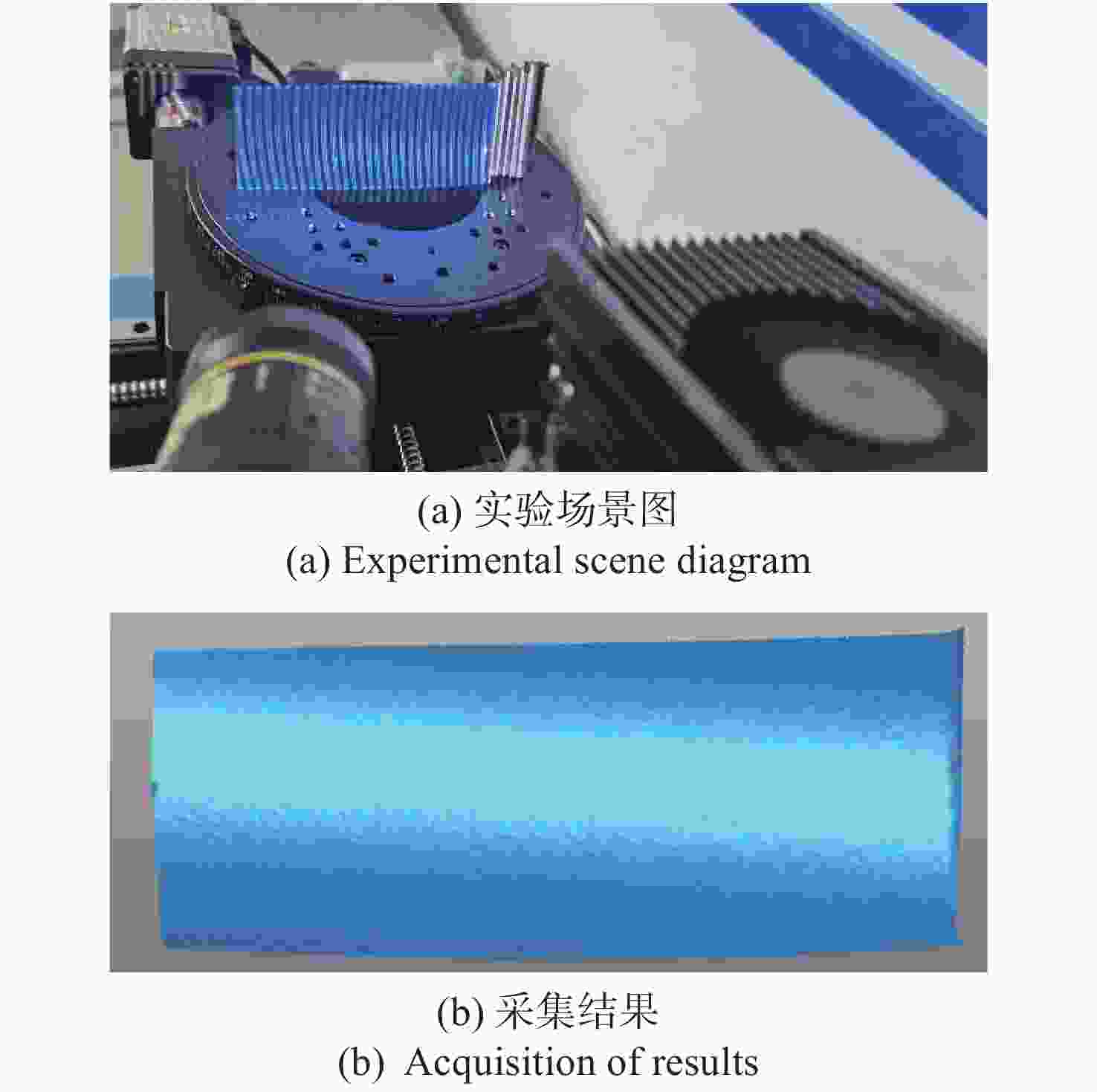

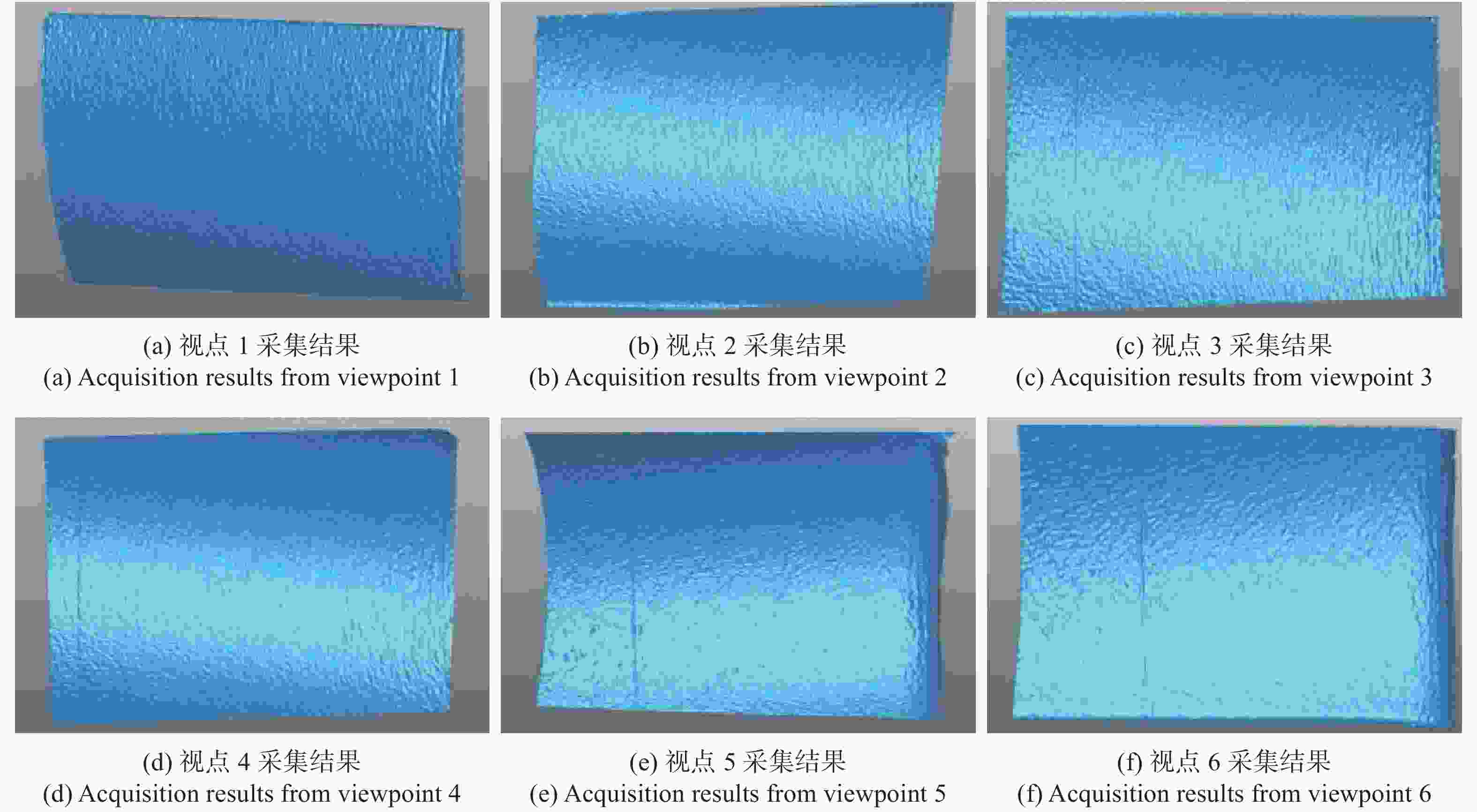

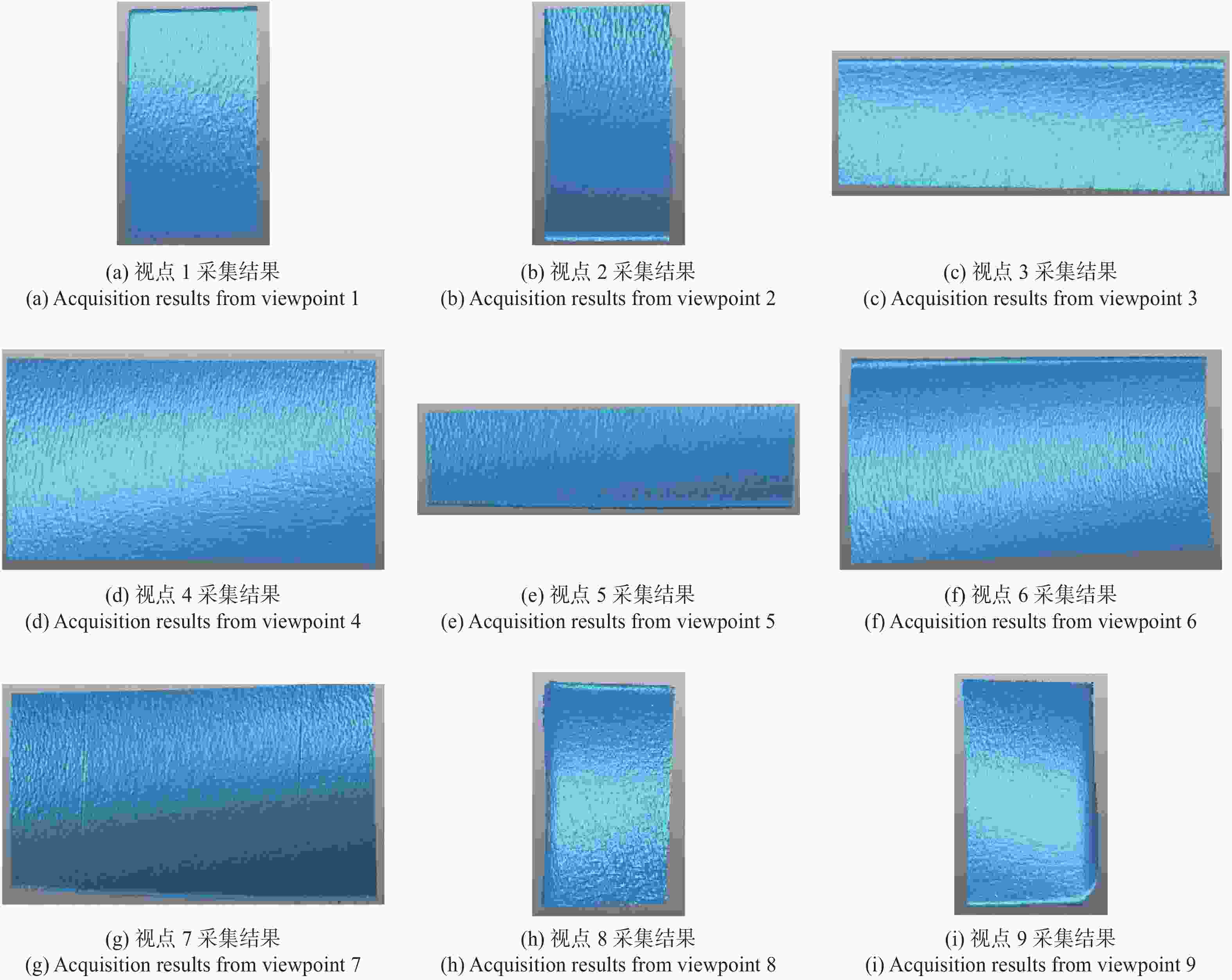

航空发动机叶片的加工质量与检测精度对于叶片的使用寿命有着十分重要的影响。本文提出一种基于结构光的高精度扫描视点规划方法以提高叶片检测精度。首先,对叶片整体尺寸进行粗扫描,获取粗模型数据,并根据相机分辨率与采集精度确定视野范围。其次,利用改进Angle Criterion算法进行边界提取,根据边界坐标与视野范围完成边界分割点的确定,利用曲面的截面线法对粗模型进行切片,根据切片结果确定内部分割点,从而完成点云均匀分割。然后,对分割后的点云数据建立有向包围盒获取中心点坐标,并对其法向量进行统计,确定主法线方向,从而生成高精度扫描的视点坐标。最后,对叶片进行表面形貌检测验证,实验结果表明,与超体素分割的视点采集结果相比,本文方法的平均标准差降低了0.0054 mm,且采集视点减少了1/3。提出的视点规划方法在薄壁叶片在机加工检测领域具有良好的应用前景。

Abstract:The machining quality and detection accuracy of aero-engine blades have a very important influence on their service life of blades. To improve the accuracy of blade detection, a high-precision scanning viewpoint planning method based on structured light is proposed in this paper. Firstly, coarse model data was obtained by coarse scanning under the overall size of the blade, and the field of view was determined according to the camera resolution and acquisition accuracy. Secondly, an improved Angle Criterion algorithm was used to extract the boundary, and the boundary segmentation points were determined according to the boundary coordinates and the range of the visual field. The coarse model was sliced by the section line method for a surface, and the internal segmentation points were determined according to the slice results to complete the uniform segmentation of point clouds. Then, a directed bounding box was established for the segmented point cloud data to obtain the coordinates of the center point, and the normal vector was statistically analyzed to determine the orientation of the main normal to generate the viewpoint coordinates for high-precision scanning. Finally, the surface morphology of the blade was tested and verified. The experimental results show that the average standard deviation of the proposed method is reduced by 0.0054 mm and the collected viewpoint is reduced by 1/3 compared with the viewpoint acquisition result of the supervoxel segmentation, which has good application prospects in the machining inspection of thin-walled blades.

-

表 1 MER-130-30UM-L型相机主要参数

Table 1. Main parameters of MER-130-30UM-L camera

性能参数 参数值 分辨率 1280(H)×1024(W) 帧率(frame·s-1) 30 传感器类型 CMOS 靶面尺寸(mm) 7.2 x 5.3 像素尺寸(μm) 5.2 x 5.2 表 2 包围盒中心点坐标值

Table 2. Coordinate values of bounding box center point

(Unit: mm) 视点位置 X坐标 Y坐标 Z坐标 点云块1 25.225 34.222 376.931 点云块2 24.617 57.156 373.603 点云块3 14.811 33.602 378.520 点云块4 15.119 57.602 376.472 点云块5 54.549 33.045 379.674 点云块6 54.706 57.098 379.530 表 3 实验数据采集结果偏差分析表

Table 3. Deviation analysis table of experimental data acquisition results

视点 点云偏差分析(mm) 偏差数据(mm) 叶片

整体

视野

尺寸

采集

本文分割方法采集结果偏差分析 超体素分割方法采集结果偏差分析 本文方法视点采集结果 点云偏差分析(mm) 偏差数据(mm) 超体素方法视点采集结果 点云偏差分析(mm) 偏差数据(mm) 视

点

1

视

点

1

视

点

2

视

点

2

视

点

3

视

点

3

视

点

4

视

点

4

视

点

5

视

点

5

视

点

6

视

点

7

视

点

6

视

点

8

视

点

9

-

[1] 冯萍, 刘震. 舵面角度测量中结构光光条图像自动定位方法[J]. 中国光学,2014,7(6):911-916.FENG P, LIU ZH. Automatic localization method of the multi-planar strip in rudder angle measurement[J]. Chinese Optics, 2014, 7(6): 911-916. (in Chinese) [2] 秦训鹏, 丁吉祥, 董寰宇, 等. 基于直线空间旋转的十字结构光标定[J]. 光学 精密工程,2021,29(6):1430-1439. doi: 10.37188/OPE.20212906.1430QIN X P, DING J X, DONG H Y, et al. Calibration of cross structured light based on linear space rotation[J]. Optics and Precision Engineering, 2021, 29(6): 1430-1439. (in Chinese) doi: 10.37188/OPE.20212906.1430 [3] GOSPODNETIĆ P, MOSBACH D, RAUHUT M, et al. Viewpoint placement for inspection planning[J]. Machine Vision and Applications, 2022, 33(1): 1-21. doi: 10.1007/s00138-021-01252-z [4] VASQUEZ-GOMEZ J I, SUCAR L E, MURRIETA-CID R. View/state planning for three-dimensional object reconstruction under uncertainty[J]. Autonomous Robots, 2017, 41(1): 89-109. doi: 10.1007/s10514-015-9531-3 [5] VASQUEZ-GOMEZ J I, SUCAR L E, MURRIETA-CID R, et al. Volumetric next-best-view planning for 3D object reconstruction with positioning error[J]. International Journal of Advanced Robotic Systems, 2014, 11(10): 159. doi: 10.5772/58759 [6] PENG W X, WANG Y N, MIAO ZH Q, et al. Viewpoints planning for active 3-D reconstruction of profiled blades using estimated occupancy probabilities (EOP)[J]. IEEE Transactions on Industrial Electronics, 2021, 68(5): 4109-4119. doi: 10.1109/TIE.2020.2987286 [7] 苏成志, 金俊杰, 毛英坤, 等. 面向未知复杂曲面的视点自主规划方法[J]. 机床与液压,2022,50(9):103-111.SU CH ZH, JIN J J, MAO Y K, et al. A method for automatic view planning of unknown complex surfaces[J]. Machine Tool &Hydraulics, 2022, 50(9): 103-111. (in Chinese) [8] MAVRINAC A, CHEN X, ALARCON-HERRERA J L. Semiautomatic model-based view planning for active triangulation 3-D inspection systems[J]. IEEE/ASME Transactions on Mechatronics, 2015, 20(2): 799-811. doi: 10.1109/TMECH.2014.2318729 [9] LEI Z K, CHEN X, CHEN X, et al. Radial coverage strength for optimization of multi-camera deployment[J]. arXiv:, 2004, 00787: 2020. [10] 朱超, 苗腾, 许童羽, 等. 基于骨架和最优传输距离的玉米点云茎叶分割和表型提取[J]. 农业工程学报,2021,37(4):188-198.ZHU CH, MIAO T, XU T Y, et al. Segmentation and phenotypic trait extraction of maize point cloud stem-leaf based on skeleton and optimal transportation distances[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(4): 188-198. (in Chinese) [11] VO A V, TRUONG-HONG L, LAEFER D F, et al. Octree-based region growing for point cloud segmentation[J]. ISPRS Journal of Photogrammetry and Remote Sensing, 2015, 104: 88-100. doi: 10.1016/j.isprsjprs.2015.01.011 [12] 王玮婕, 薛河儒, 武晓东, 等. 基于法线估计的鼢鼠头骨三维点云分割算法[J]. 应用金宝搏188软件怎么用 ,2022,42(5):141-150.WANG W J, XUE H R, WU X D, et al. Three-dimensional point cloud segmentation algorithm of Zokor skull based on normal estimation[J]. Applied Laser, 2022, 42(5): 141-150. (in Chinese) [13] 张兴岩, 李琦, 梁栋, 等. 一种邻接区域平面元融合的桥面分割方法[J]. 大地测量与地球动力学,2022,42(8):863-869.ZHANG X Y, LI Q, LIANG D, et al. A bridge deck segmentation method based on fusion of plane elements in adjacent regions[J]. Journal of Geodesy and Geodynamics, 2022, 42(8): 863-869. (in Chinese) [14] 李茂月, 刘泽隆, 赵伟翔, 等. 面结构光在机检测的叶片反光抑制技术[J]. 中国光学,2022,15(3):464-475. doi: 10.37188/CO.2021-0194LI M Y, LIU Z L, ZHAO W X, et al. Blade reflection suppression technology based on surface structured light on-machine detection[J]. Chinese Optics, 2022, 15(3): 464-475. (in Chinese) doi: 10.37188/CO.2021-0194 [15] ARGÜELLES-FRAGA R, ORDÓÑEZ C, GARCÍA-CORTÉS S, et al. Measurement planning for circular cross-section tunnels using terrestrial laser scanning[J]. Automation in Construction, 2013, 31: 1-9. doi: 10.1016/j.autcon.2012.11.023 [16] GRONLE M, OSTEN W. View and sensor planning for multi-sensor surface inspection[J]. Surface Topography:Metrology and Properties, 2016, 4(2): 024009. doi: 10.1088/2051-672X/4/2/024009 [17] GALLARDO-GUTIÉRREZ E A, PARTINGTON J R. Supercyclic vectors and the angle criterion[J]. Studia Mathematica, 2005, 166(1): 93-99. doi: 10.4064/sm166-1-7 [18] 郑鹏飞, 邹培玲, 赵菊娣, 等. 点云曲面空间网格化加密求交算法[J]. 浙江大学学报(工学版),2018,52(3):605-612.ZHENG P F, ZOU P L, ZHAO J D, et al. Intersection algorithm of point cloud surface by spatial mesh and refinement[J]. Journal of Zhejiang University (Engineering Science), 2018, 52(3): 605-612. (in Chinese) [19] 陈岳坪, 靳龙, 卢海燕, 等. 基于三角网格模型的复杂曲面测点规划[J]. 机床与液压,2015,43(23):42-45,53.CHEN Y P, JIN L, LU H Y, et al. Measured point planning of complex surfaces based on triangular mesh models[J]. Machine Tool &Hydraulics, 2015, 43(23): 42-45,53. (in Chinese) [20] 王张飞, 刘春阳, 隋新, 等. 基于深度投影的三维点云目标分割和碰撞检测[J]. 光学 精密工程,2020,28(7):1600-1608. doi: 10.37188/OPE.20202807.1600WANG ZH F, LIU CH Y, SUI X, et al. Three-dimensional point cloud object segmentation and collision detection based on depth projection[J]. Optics and Precision Engineering, 2020, 28(7): 1600-1608. (in Chinese) doi: 10.37188/OPE.20202807.1600 -

下载:

下载: