Optimization of structural parameters and fabrication of monocrystalline silicon gratings with small blazed angle

-

摘要:

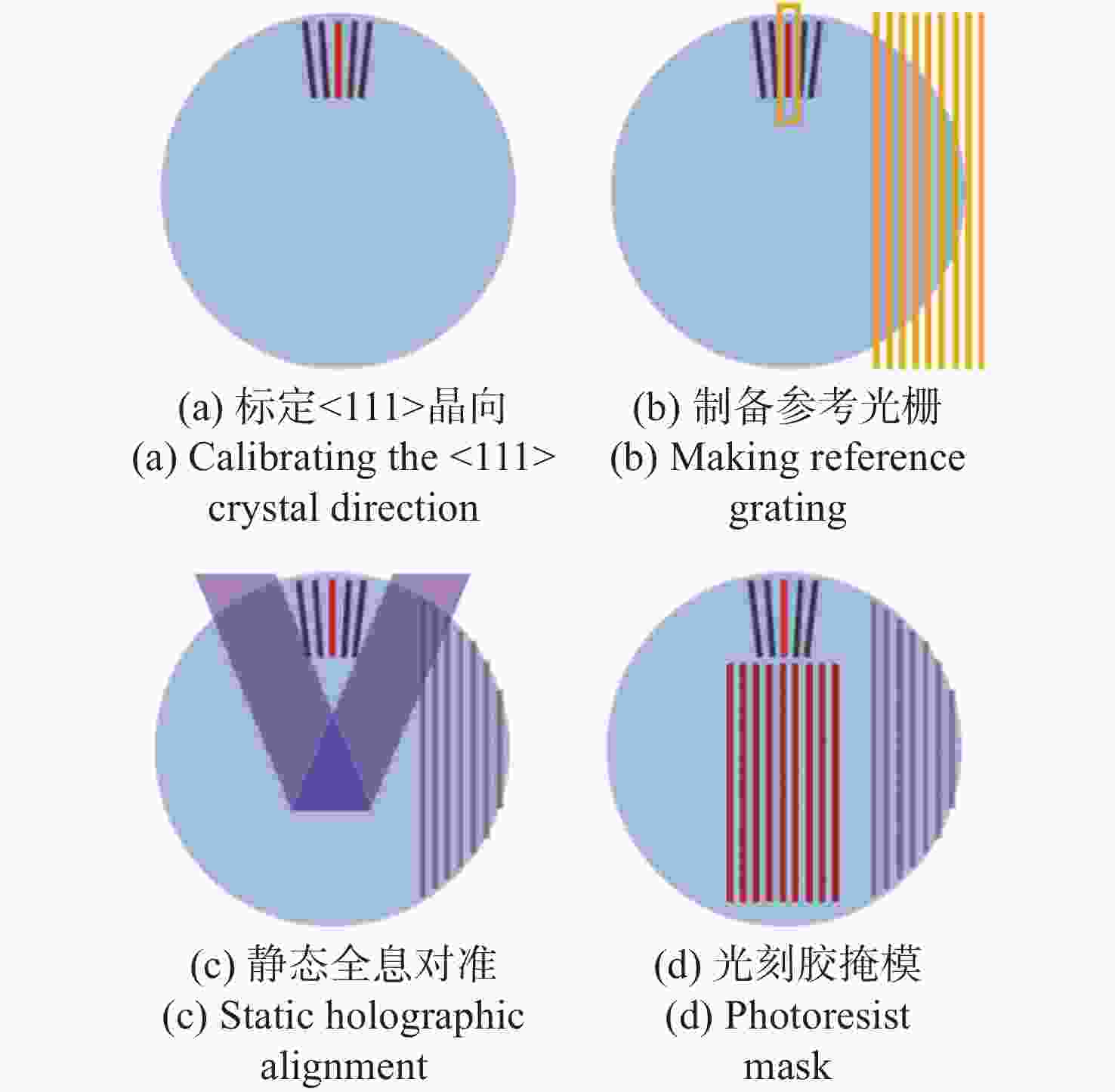

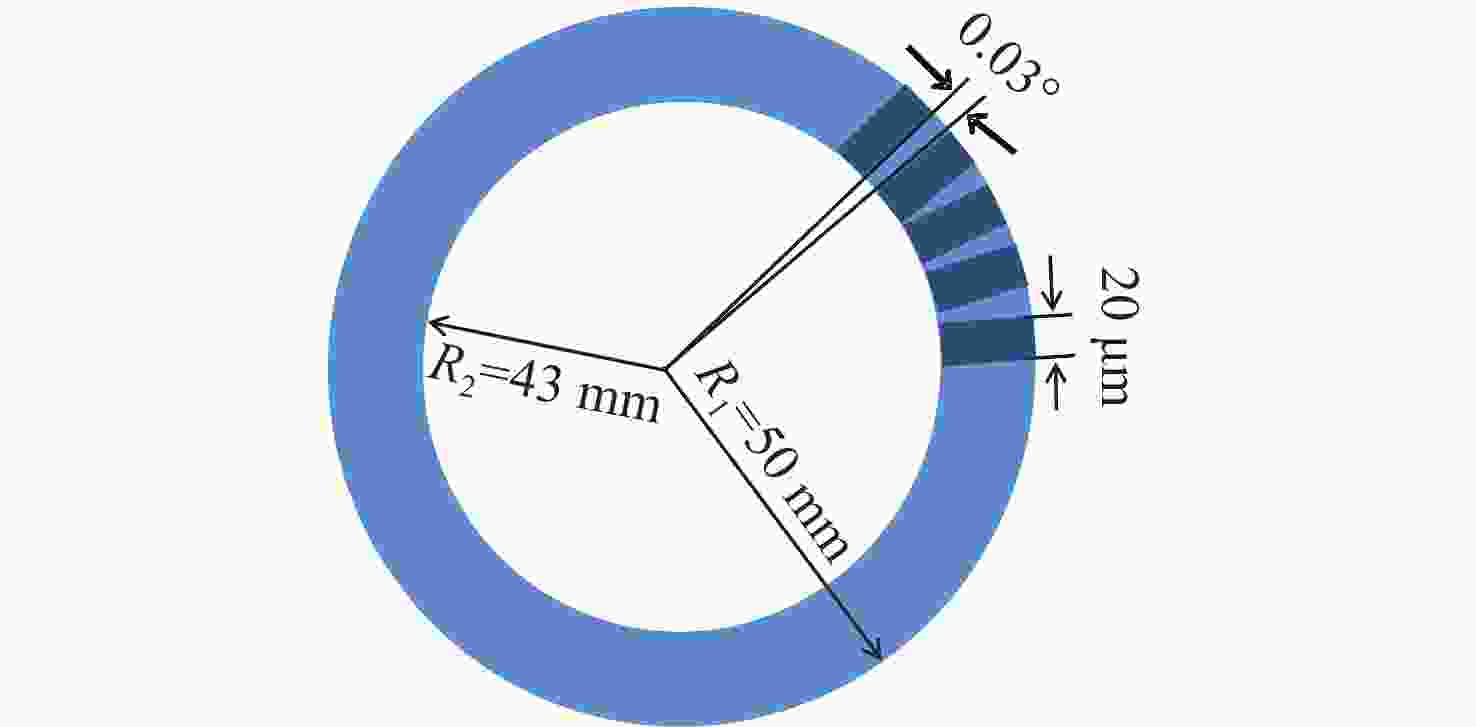

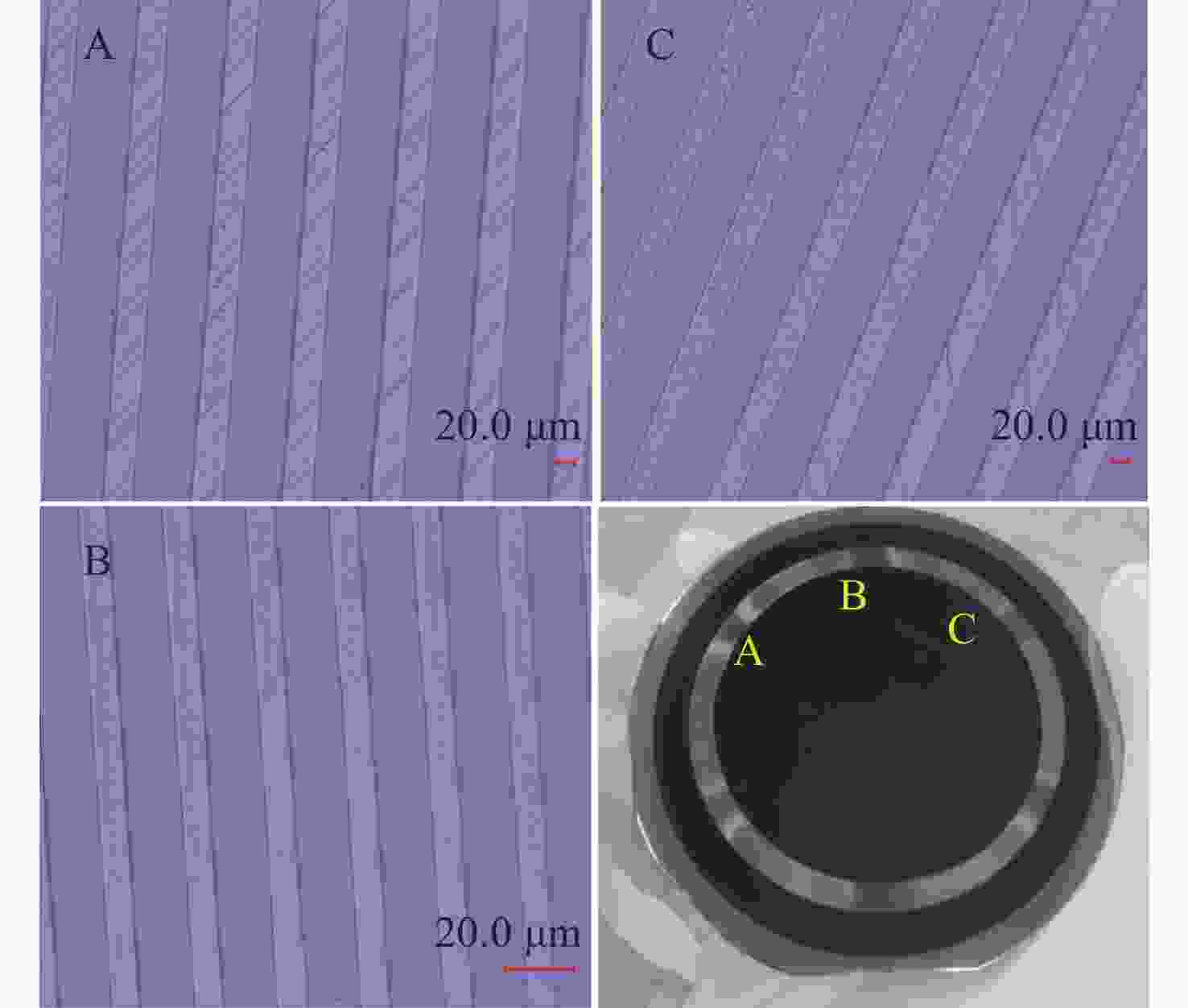

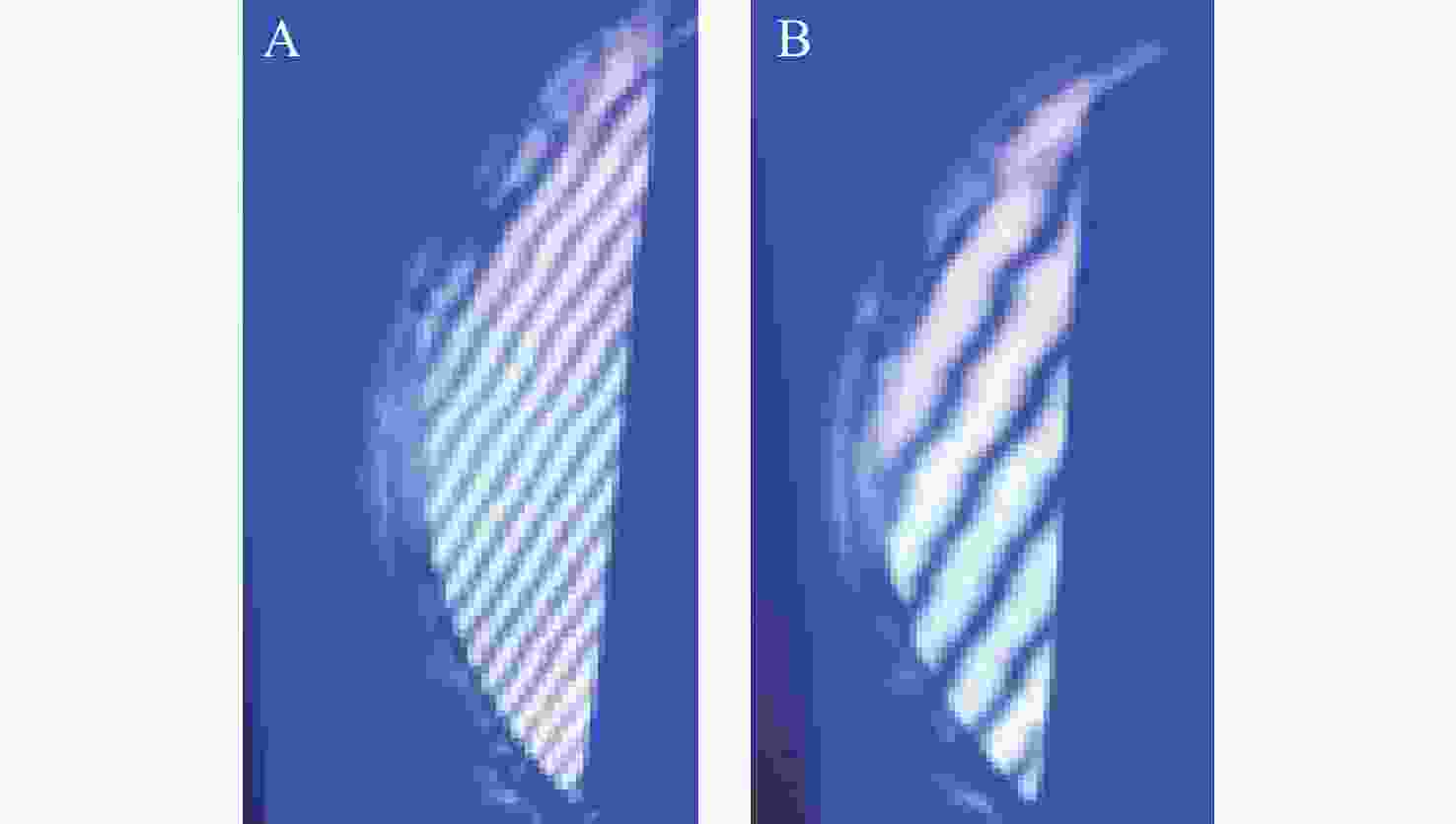

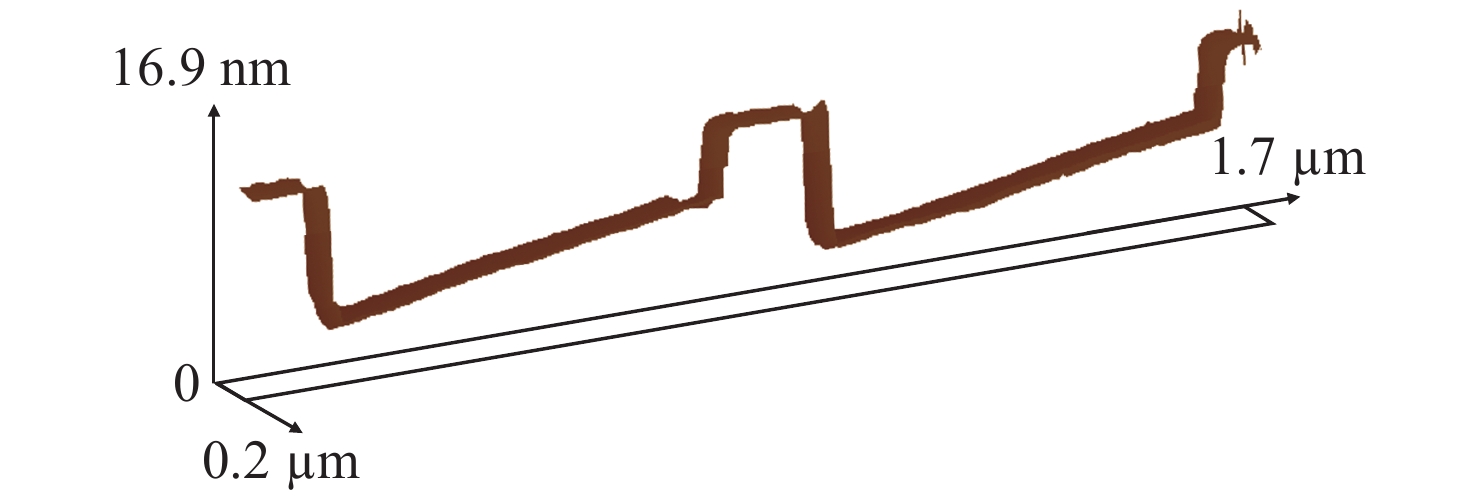

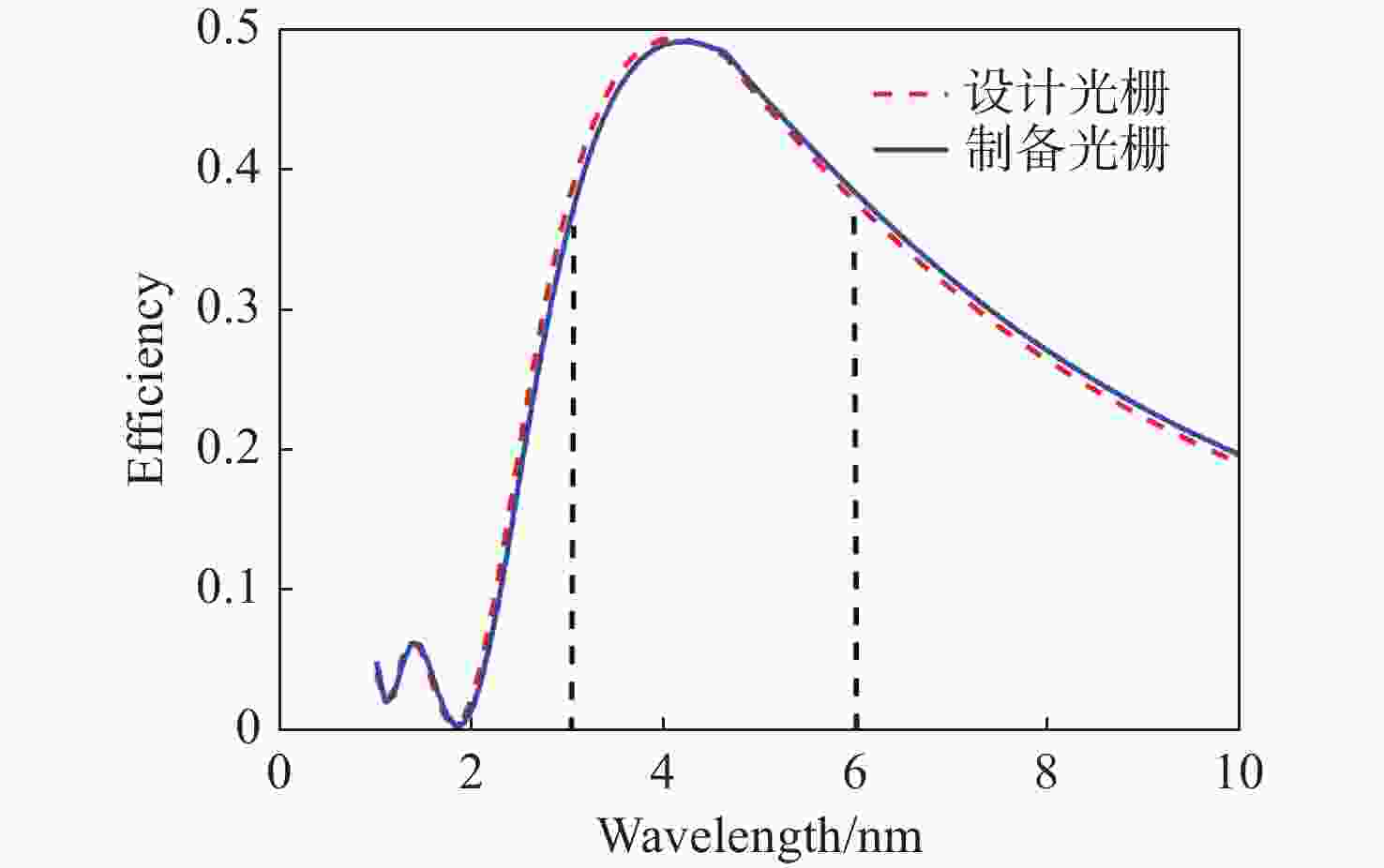

本文开展了对单晶硅小闪耀角光栅的各向异性湿法刻蚀制备工艺研究,制备了适用于软X射线中波波段的闪耀光栅,以满足国家同步辐射光源的需要。首先,基于严格耦合波法对小闪耀角光栅进行了结构参数优化及工艺容差分析。在晶向对准过程中,先通过环形预刻蚀确定硅片晶向,再基于倍频调整法实现光栅掩模与单晶硅<111>晶向的对准。研究了光刻胶灰化技术及活性剂对光栅槽形质量的影响,并通过单晶硅各向异性湿法刻蚀工艺成功制备了接近于理想锯齿槽形的闪耀光栅。实验结果证明:所制备光栅闪耀角为1°,刻线密度为

1200 gr/mm,闪耀面均方根粗糙度在0.5 nm以内。此方法可以应用于软X射线中波波段闪耀光栅的制作,在获得较高衍射效率的同时可以大大减少制作难度及成本。Abstract:In order to meet the requirements of the national synchrotron radiation source, the anisotropic wet-etching technology of monocrystalline silicon grating with small blazed angle is studied, and the blazed grating suitable for the medium wave soft X-ray band is prepared. Based on the rigorously coupled wave theory, the structural parameters and process tolerance of the small blazed angle grating are designed. In the crystal alignment process, the crystal orientation of the silicon wafer is determined by ring-preetching, and then the grating mask is aligned with the crystal direction of monocrystalline silicon <111> based on the frequency doubling adjustment method. At the same time, the effect of the photoresist ashing technique and the active agent on the groove quality of the grating is investigated, and the scintillating gratings close to the ideal sawtooth groove shape are successfully prepared by the monocrystalline silicon anisotropic wet etching process. The experimental results show that the blazed angle of the prepared grating is 1°, the linear density is

1200 gr/mm, and the root mean square roughness of the blazed surface is less than 0.5 nm. This method can be applied to the fabrication of the medium wave soft X-ray blazed grating, which can greatly reduce the difficulty and cost of fabrication while achieving high diffraction efficiency.-

Key words:

- blazed grating /

- monocrystalline silicon /

- crystalline alignment /

- wet etching

-

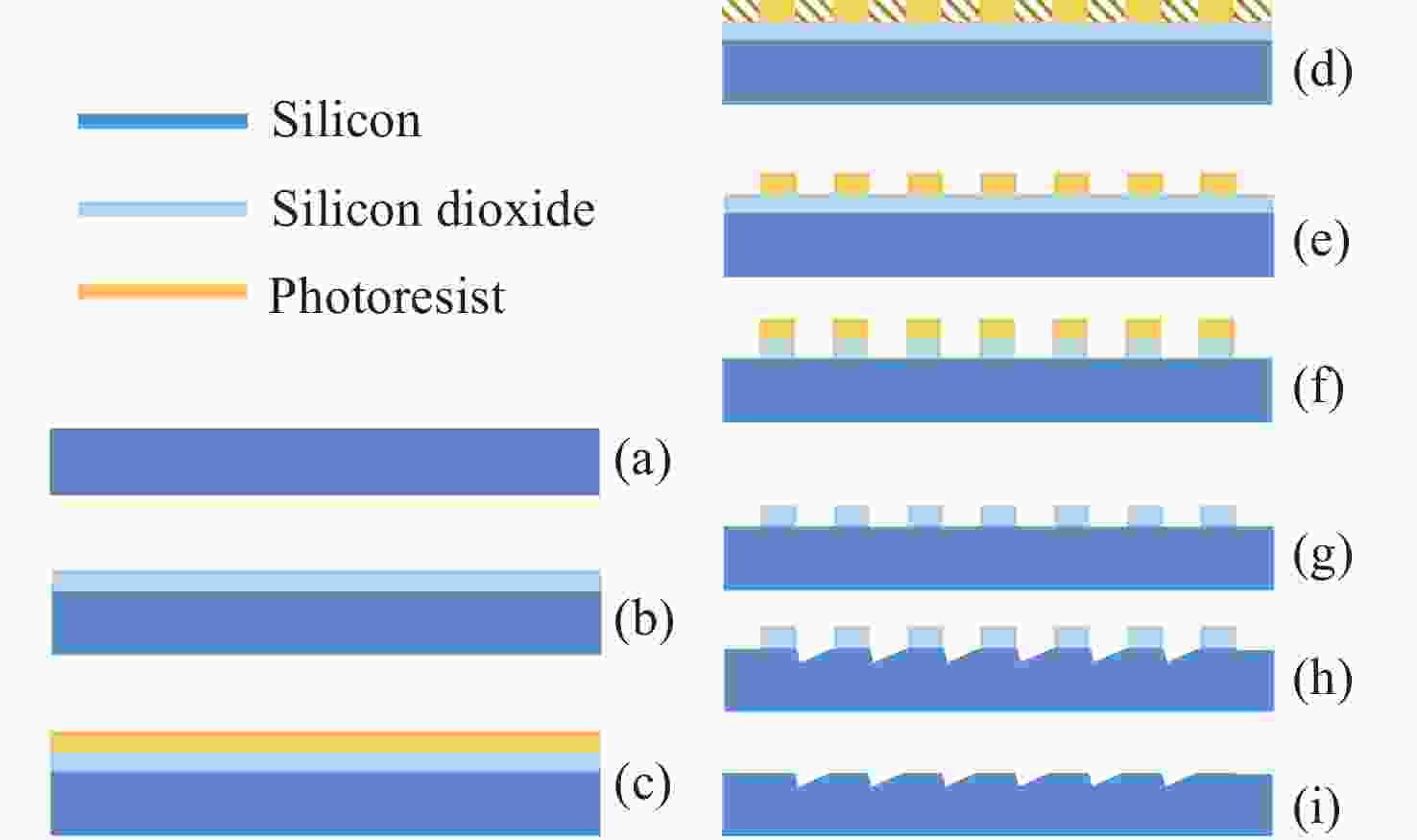

图 14 光栅制备工艺流程。(a)硅片清洁;(b)氧化层制备;(c)旋涂光刻胶;(d)对准曝光;(e)显影;(f)光刻胶图形转移;(g)氧化层掩模制备;(h)湿法刻蚀;(i)去除表面掩模

Figure 14. Grating preparation process. (a) Silicon wafer cleaning; (b) preparation of oxide layer; (c) spin coated photoresist; (d) alignment exposure; (e) development; (f) photoresist pattern transfer; (g) preparation of oxide mask; (h) wet etching; (i) remove the surface mask

表 1 光栅技术指标

Table 1. Specification of grating

指标参数 数值 波长范围/nm 3~6 衍射级次 −1 入射状态 掠入射 衍射效率 >40% 表 2 光栅槽形参数

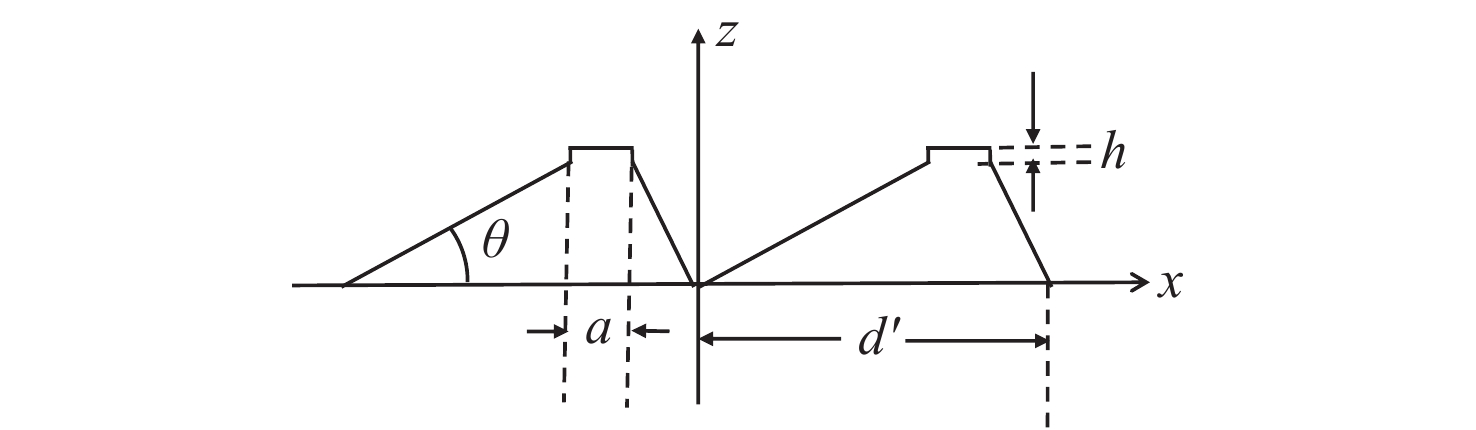

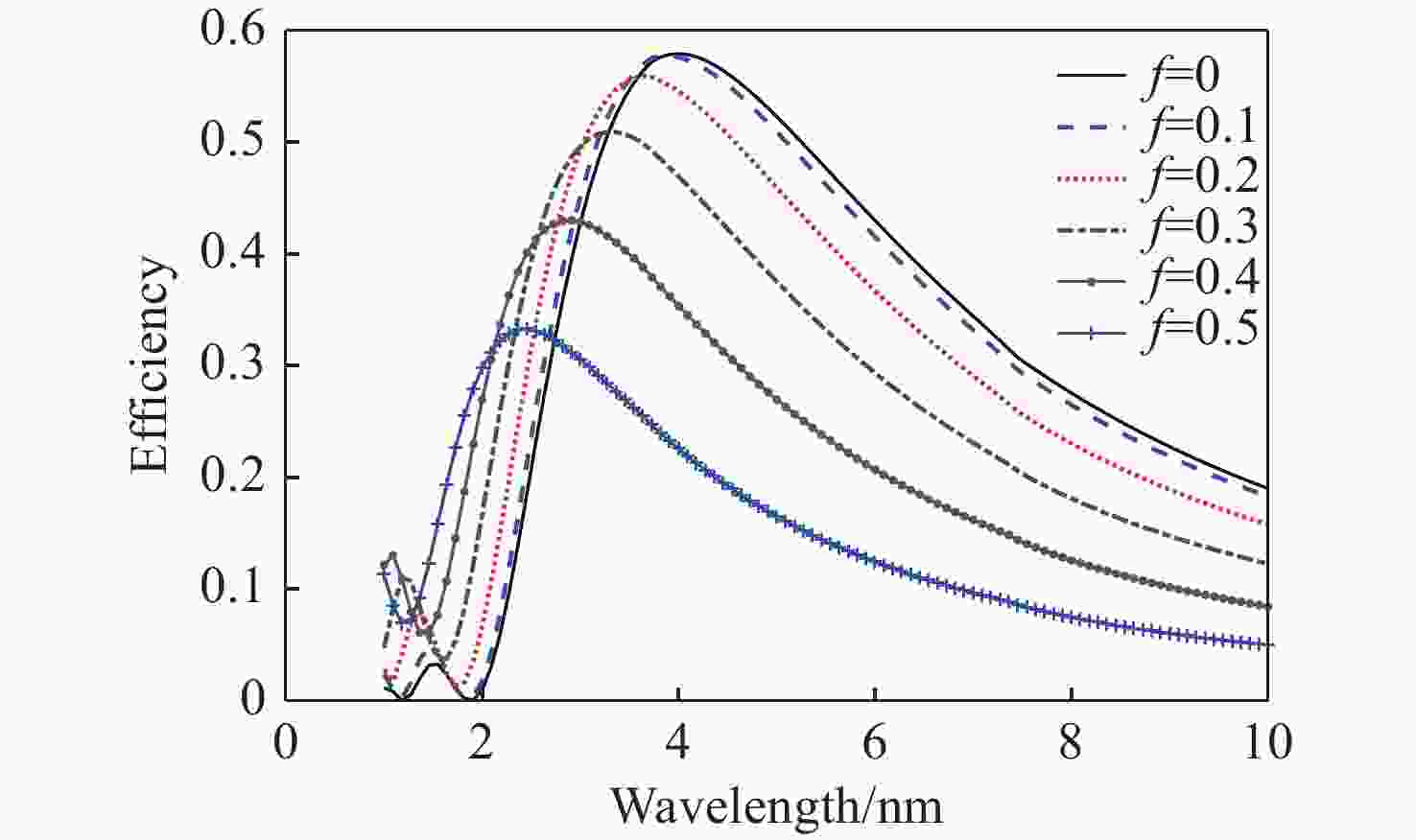

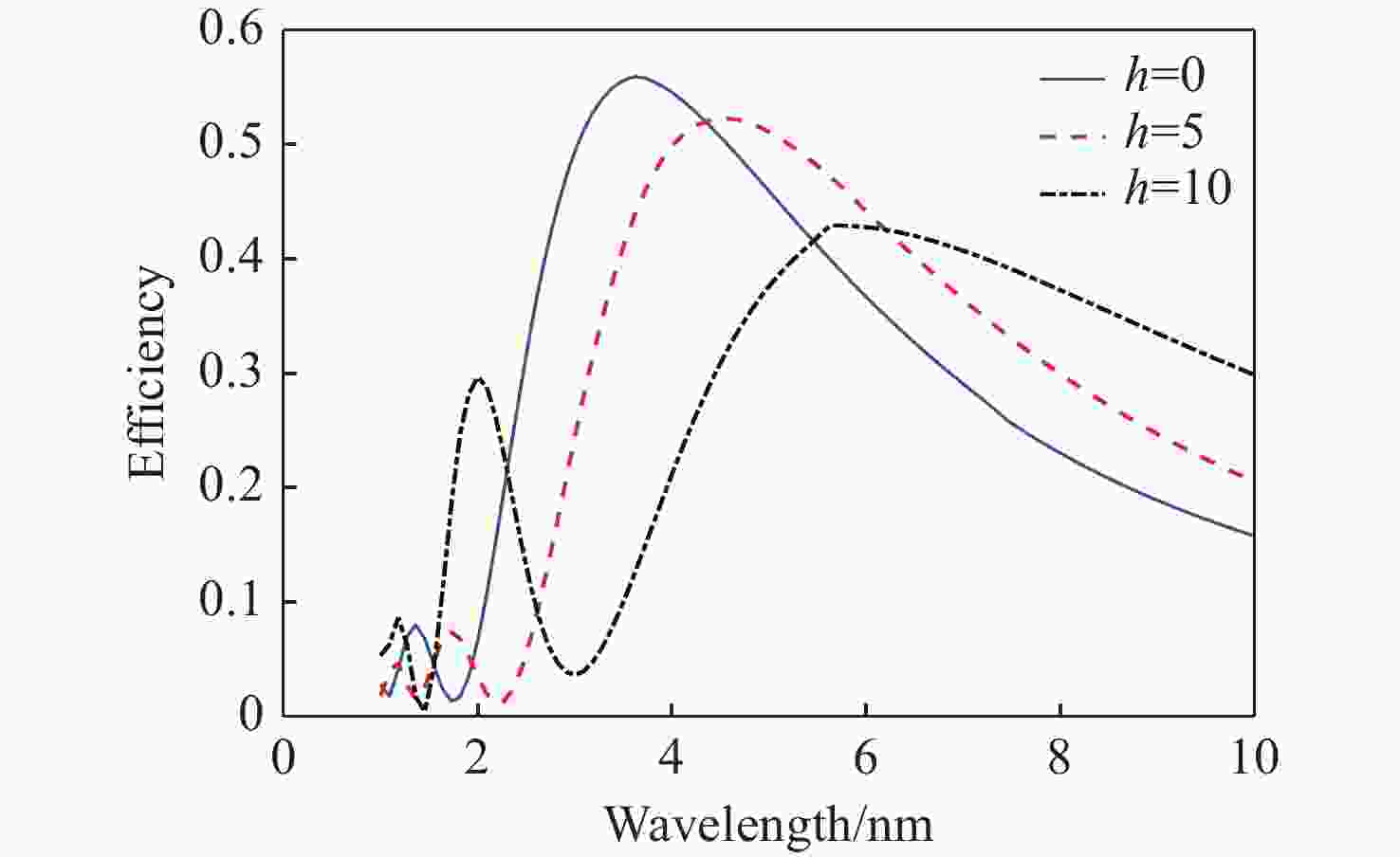

Table 2. Grating groove parameters

槽形参数 数值 闪耀角/(°) 1±0.1 周期/nm 833 f 0<f<0.3 h/nm 0<h<8 表 3 AFM粗糙度测量结果

Table 3. AFM roughness measurement results (Unit: nm)

测量点 Rq 1 0.287 2 0.436 3 0.365 4 0.253 5 0.220 6 0.379 7 0.409 8 0.293 9 0.333 10 0.400 平均值 0.3375 表 4 闪耀角测量结果

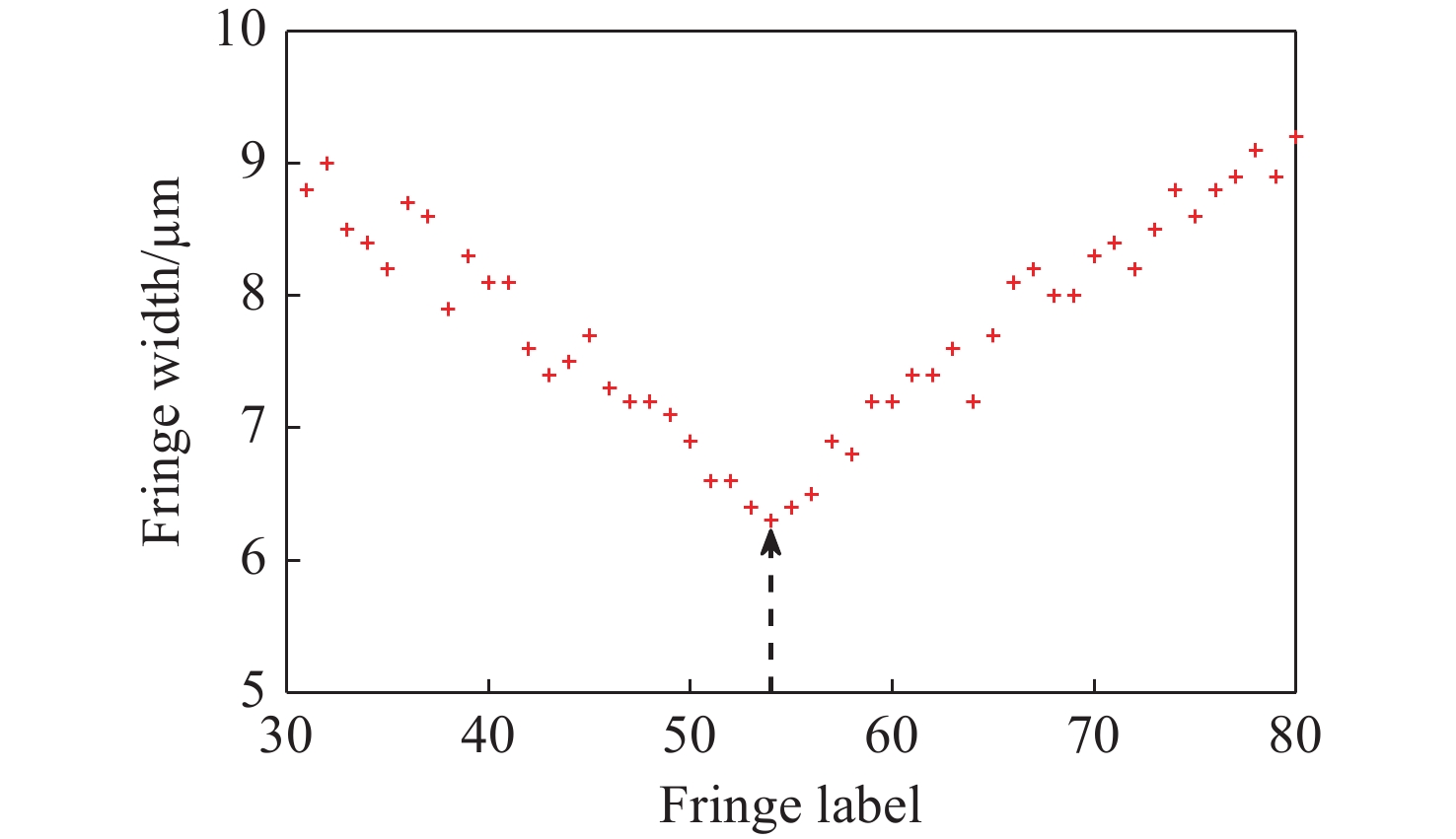

Table 4. Blazed angle measurement results

测量点 闪耀角 1 0.969° 2 1.023° 3 0.974° 4 1.015° 5 1.009° 平均值 0.998° -

[1] 焦毅, 潘卫民. 高能同步辐射光源[J]. 强金宝搏188软件怎么用 与粒子束,2022,34(10):104002.JIAO Y, PAN W M. High energy photon source[J]. High Power Laser and Particle Beams, 2022, 34(10): 104002. (in Chinese) [2] JIN S SH, ZHAO Y K, SUN B G, et al. Design of an interference system for measuring the transverse beam size in HLS-II[J]. International Journal of Optomechatronics, 2022, 16(1): 18-28. doi: 10.1080/15599612.2022.2048151 [3] JOSIFOVSKA N, ANDJELIC S, LUMI X, et al. Synchrotron-based FTIR microspectroscopy of human primary retinal pigmented epithelial cells as a model for age-related macular degeneration[J]. Acta Ophthalmologica, 2022, 100(S275). [4] NALETTO G, TONDELLO G, CIMINO R. Design of a high-flux low-energy synchrotron radiation monochromator[J]. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2006, 556(1): 371-378. [5] ALEXANDER J, BANERJEE N, VAN LOON L. Application of synchrotron radiation X-ray diffraction (SR-XRD) and electron probe microanalysis to understanding gold mineralization at the vertigo target, White Gold District, west-Central Yukon Territory, Canada[J]. Microscopy and Microanalysis, 2020, 26(S2): 994-997. doi: 10.1017/S1431927620016608 [6] WADDINGHAM M T, TSUCHIMOCHI H, SONOBE T, et al. Using synchrotron radiation imaging techniques to elucidate the actions of hexarelin in the heart of small animal models[J]. Frontiers in Physiology, 2022, 12: 766818. doi: 10.3389/fphys.2021.766818 [7] 张宝庆, 于硕, 吉日嘎兰图, 等. 铝膜层数对机械刻划光栅塑性成槽过程的影响[J]. 塑性工程学报,2021,28(10):141-147.ZHANG B Q, YU SH, JIRIGALANTU, et al. Effect of aluminum film layer number on plastic grooving process of mechanical grating ruling[J]. Journal of Plasticity Engineering, 2021, 28(10): 141-147. (in Chinese) [8] JIRIGALANTU, LI X T, ZHANG SH W, et al. Ruling of echelles and gratings with a diamond tool by the torque equilibrium method[J]. Applied Optics, 2016, 55(28): 8082-8088. doi: 10.1364/AO.55.008082 [9] MAMUN M A A, CADUSCH P J, KATKUS T, et al. Quantifying end-face quality of cleaved fibers: femtosecond laser versus mechanical scribing[J]. Optics and Laser Technology, 2021, 141: 107111. doi: 10.1016/j.optlastec.2021.107111 [10] 王琼, 沈晨, 谭鑫, 等. 摆动刻蚀法制作高衍射效率凸面闪耀光栅[J]. 强金宝搏188软件怎么用 与粒子束,2019,31(6):061001. doi: 10.11884/HPLPB201931.180298WANG Q, SHEN CH, TAN X, et al. Fabrication of high-efficiency convex blazed gratings by swing ion beam etching[J]. High Power Laser and Particle Beams, 2019, 31(6): 061001. (in Chinese) doi: 10.11884/HPLPB201931.180298 [11] ZHANG K D, LI H SH, ZHANG CH, et al. Effect of ion beam etching on the tribological performance of laser textured Co-Cr-Mo alloy[J]. Optics & Laser Technology, 2023, 160: 109097. [12] SHEN CH, TAN X, JIAO Q B, et al. Convex blazed grating of high diffraction efficiency fabricated by swing ion-beam etching method[J]. Optics express, 2018, 26(19): 25381-25398. doi: 10.1364/OE.26.025381 [13] 杨子江, 潘俏, 朱嘉诚, 等. 紫外光刻-湿法刻蚀硅中阶梯光栅的研制[J]. 光学学报,2023,43(13):1305001. doi: 10.3788/AOS230446YANG Z J, PAN Q, ZHU J CH, et al. Fabrication of silicon echelle grating by ultraviolet lithography combined with wet etching[J]. Acta Optica Sinica, 2023, 43(13): 1305001. (in Chinese) doi: 10.3788/AOS230446 [14] GAO J, CHEN P, WU L, et al. A review on fabrication of blazed gratings[J]. Journal of Physics D:Applied Physics, 2021, 54(31): 313001. doi: 10.1088/1361-6463/abfd6a [15] 聂秋玉. 基于偏晶向(111)硅基的MOEMS扫描光栅微镜关键技术研究[D]. 重庆: 重庆大学, 2017.NIE Q Y. Research on key technologies of MOEMS scanning grating mirror based on tilted (111) silicon wafer[D]. Chongqing: Chongqing University, 2017. (in Chinese) [16] JIAO Q B, ZHU CH L, TAN X, et al. The effect of ultrasonic vibration and surfactant additive on fabrication of 53.5 gr/mm silicon echelle grating with low surface roughness in alkaline KOH solution[J]. Ultrasonics Sonochemistry, 2018, 40: 937-943. doi: 10.1016/j.ultsonch.2017.09.011 [17] SHENG B, XU X D, LIU Y, et al. Vacuum-ultraviolet blazed silicon grating anisotropically etched by native-oxide mask[J]. Optics Letters, 2009, 34(8): 1147-1149. doi: 10.1364/OL.34.001147 [18] VORONOV D L, LUM P, NAULLEAU P, et al. X-ray diffraction gratings: precise control of ultra-low blaze angle via anisotropic wet etching[J]. Applied Physics Letters, 2016, 109: 043112. doi: 10.1063/1.4960203 [19] MOKHOV D V, BEREZOVSKAYA T N, SHUBINA K Y, et al. Optimization of triangular-profiled Si-grating fabrication technology for EUV and SXR applications[J]. Technical Physics, 2022, 67(8): 1009-1014. -

下载:

下载: